Apparatus and method for checking at least one solder joint between a printed circuit board and a current sensor

A technology of current sensor and welding part, which is applied in the direction of adopting electrical devices, voltage/current isolation, measuring devices, etc., can solve the problems of increasing production costs, and achieve the effect of saving circuit consumption and saving external processors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

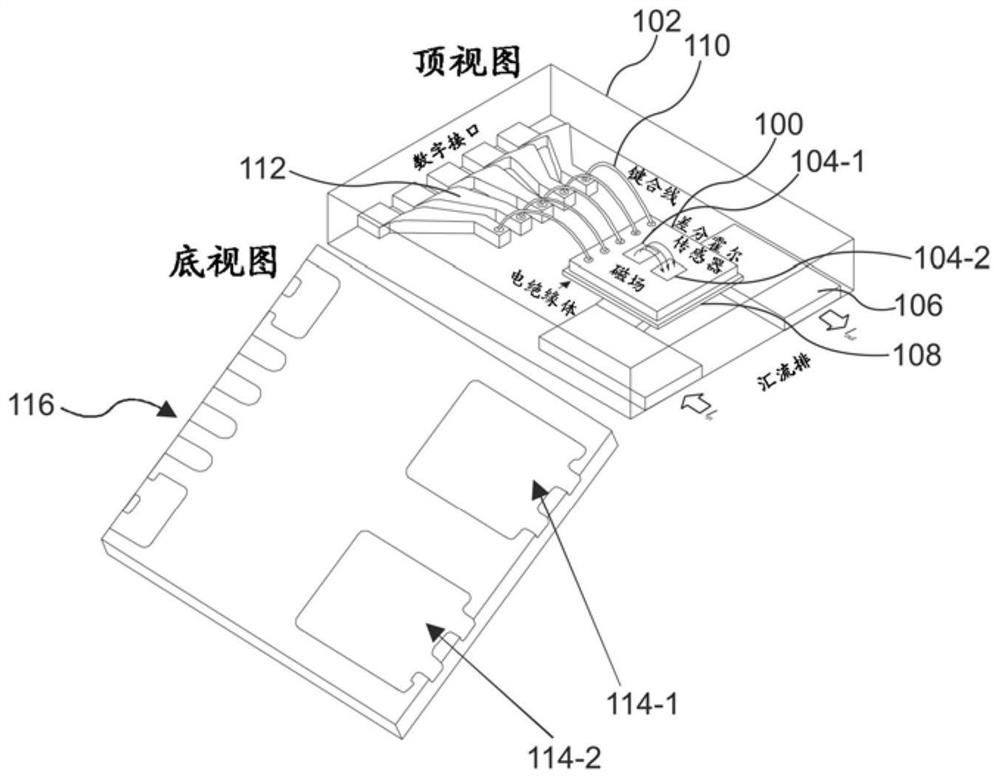

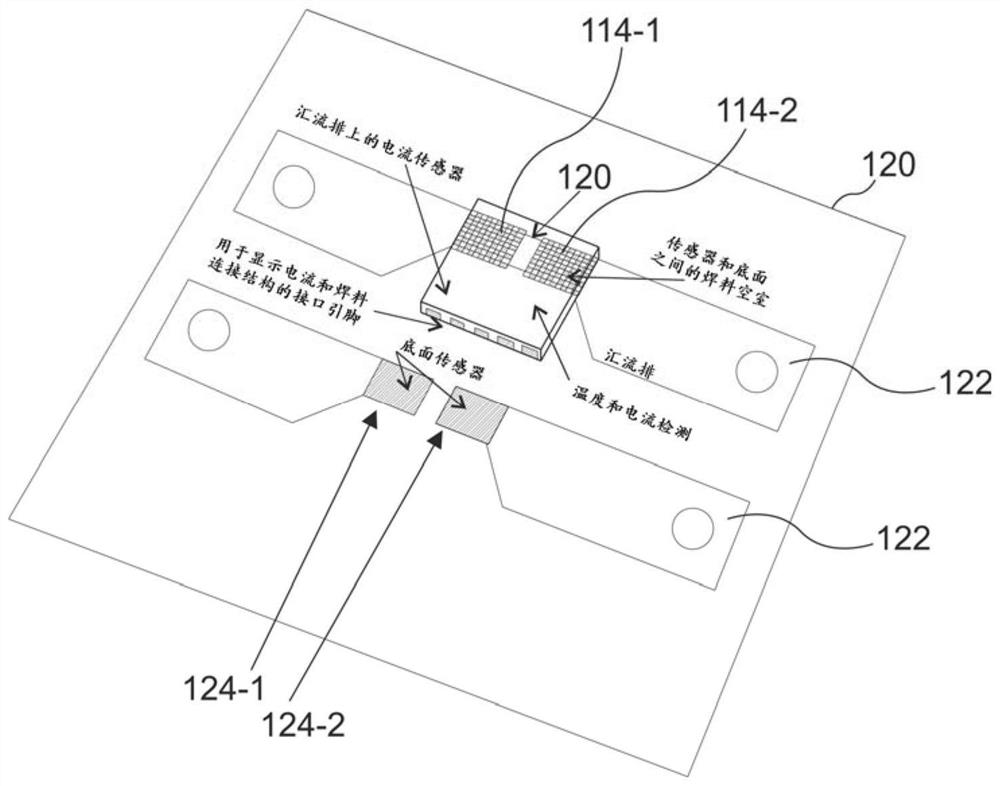

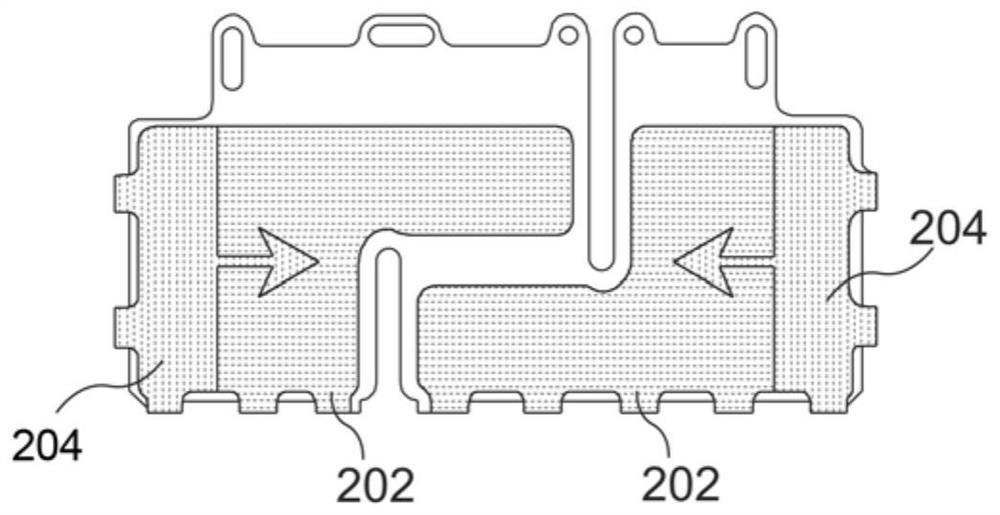

[0026] Various examples will now be described more fully with reference to the accompanying drawings in which some examples are shown. In the drawings, the thickness of lines, layers and / or regions may be exaggerated for clarity.

[0027] Therefore, while further examples are capable of various modifications and alternative forms, some specific examples thereof are shown in the drawings and described in detail later. However, this detailed description does not limit the additional examples to the specific forms described. Additional examples may cover all modifications, equivalents, and alternatives falling within the scope of the disclosure. Like reference numerals denote like or similar elements in the description of the figures, which when compared to each other may be implemented in the same or in a modified form, while providing the same or similar functions.

[0028] It will be understood that when an element is referred to as being "connected" or "coupled" to another ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com