Resistance voltage division circuit

A resistance voltage divider circuit and voltage divider resistance technology, applied in electrical components, adjusting electrical variables, instruments, etc., can solve problems such as longer delay time, increased resistance value, and slow response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

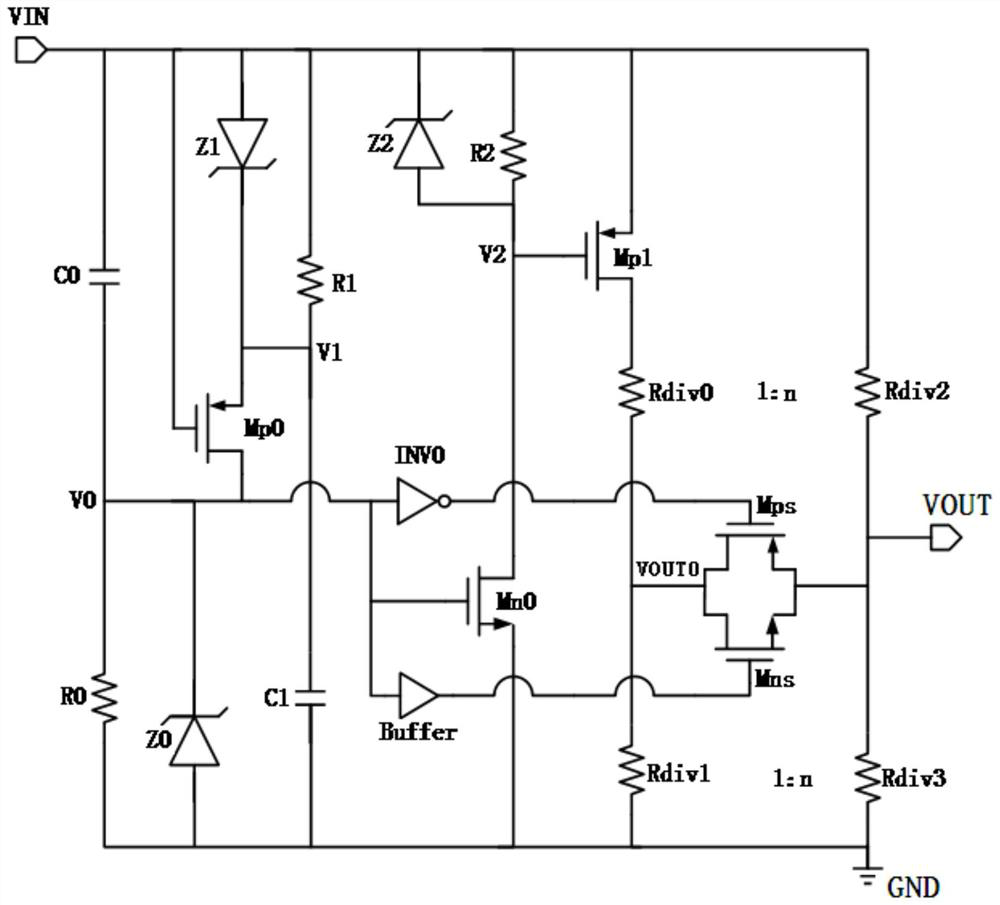

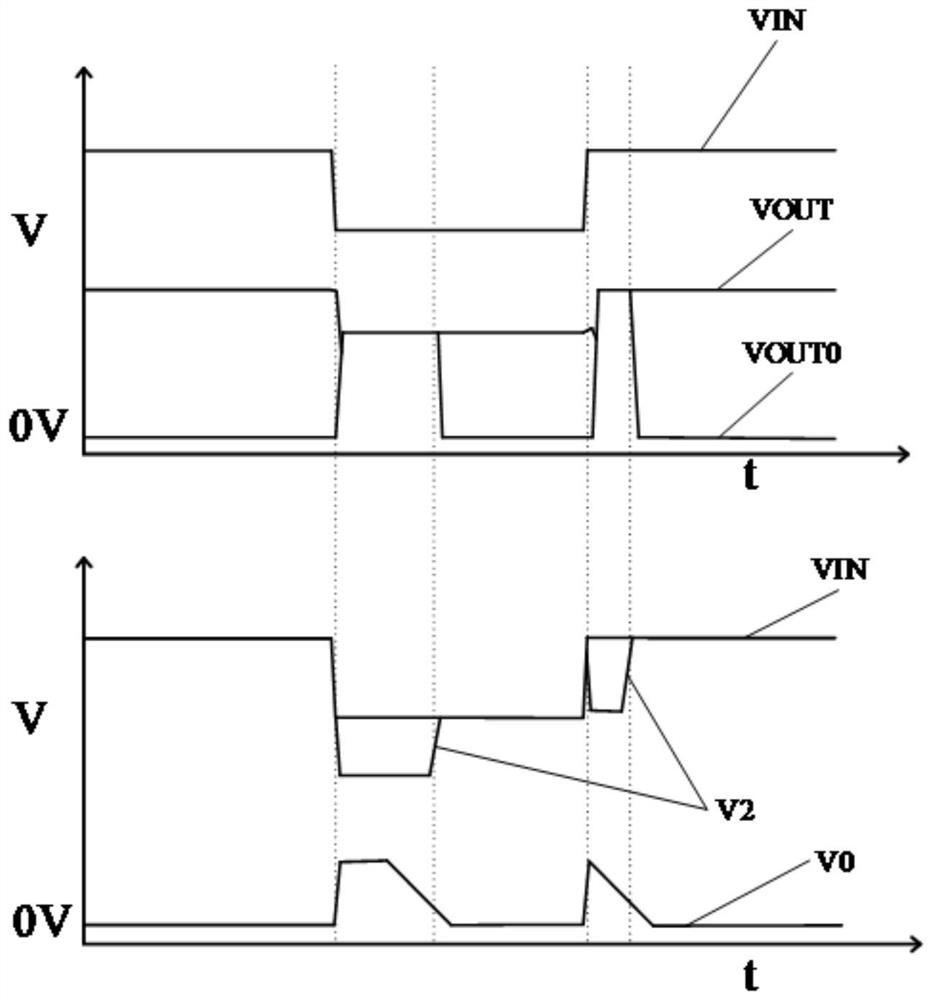

[0017] Below with the accompanying drawings ( Figure 1-Figure 2 ) to illustrate the present invention.

[0018] figure 1 It is a structural schematic diagram of a resistive voltage divider circuit implementing the present invention. figure 2 is in figure 1 A schematic diagram of the waveforms of the first node V0, the second node V1, the third node V2, the fourth node VOUT0, the input voltage terminal VIN and the output voltage terminal VOUT. Such as Figure 1 to Figure 2 As shown, a resistor divider circuit includes a voltage output terminal VOUT, and the voltage output terminal VOUT is respectively connected to one end of the third divider resistor Rdiv2, one end of the fourth divider resistor Rdiv3, and the source of the first NMOS switch tube Mns and the source of the second PMOS switch tube Mps, the other end of the third voltage dividing resistor Rdiv2 is connected to the voltage input terminal VIN, the other end of the fourth voltage dividing resistor Rdiv3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com