Method for improving emulsibility of alkaline extracted leaf biomass protein through enzymolysis chemical bonds and application of biomass protein as emulsifier

A biomass and protein technology, which is applied in food ingredients as emulsifiers, protein-containing food ingredients, food ingredients as antimicrobial preservation, etc., to improve product quality, improve texture characteristics, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

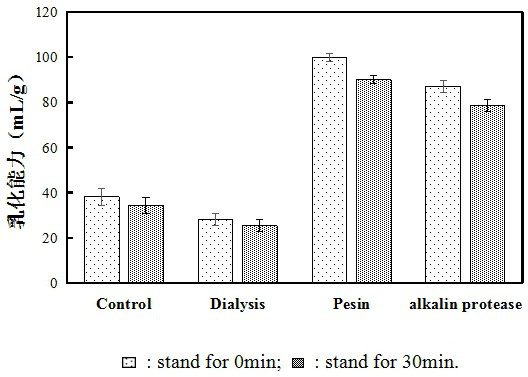

[0040] In order to make the objects and advantages of the present invention more clearly, the present invention will be described in detail below, but the embodiments described herein are intended to be used herein, and is not intended to limit the invention. Example 1

[0041] First extract protein products using alkali method:

[0042] (a): Tea pretreatment: eliminate poor leaves, cleans the dry leaves after cleaning;

[0043] (b): Extraction: The mass ratio of the pulp powder and the alkali solution obtained by step (a) is mixed according to the ratio of 1: 8, and a mixture is obtained after stirring at 95 ° C; the base solution is pH. 7 NaOH solution; (c): Separate: The mixture obtained by step (b) is separated to obtain an extract containing a protein complex;

[0044] (d): Purification: The extract obtained by the step (c) was mixed with 1 M HCl, pH adjusted to 3.5, precipitated, mixed with mixed separation, and obtained precipitation of the protein complex and reconciled wi...

Example Embodiment

[0051] Example 2: Preparation of emulsified sausages

[0052] (A): Raw meat trim: Put the fresh pig behind the legs, white, peeled off, remove bones, dirt. Tap the eggs, warm water, and drain the water, the dirt, etc., 100g.

[0053] (B): Marinated: Picking the salt 3G directly in the meat obtained by the step (a), marinated in the cold storage of 0 ~ 4 ° C, 4 hours or so, the marker of the marinated marker is 痩Pork showed uniform bright red, strong and elastic, stranded.

[0054] (C): Chopping: Extract the meat obtained by step (b), opening the chopping machine, adding ice water 71 kg, slowly adding taste 0.44 kg, white sugar 3.4 kg, red curved 0.006 kg, carmine Red 0.008 kg, Rouge Tree Orange 0.004 kg, temptation Red 0.002 kg, corn starch 8.0 kg, corn degenerative starch 8.0 kg, tripolyphosphate 0.6 kg, nitrite 0.004 kg, karaperin 1.0 kg, white pepper 0.24 kg, The compound preservative 0.6 kg, 0.03 kg of disadvantageous sodium, sodium lactate 4.0 kg, 0.6 kg of pork flavor. Emuls...

Example Embodiment

[0062] Example 3: Preparation of a cake

[0063] The main ingredient of the cake is egg white, low-gluten and sugar, and basic formulas are as follows.

[0064] Cake formula

[0065]

[0066] Other proteins are: soybean separation proteins, (alkali) tea slag proteins and (alkali + enzymatic) tea residue protein.

[0067] (A): Euta / (egg white protein + other protein) + tower powder + salt mixed, other protein concentrations of 10%, whitening to the medium speed gear to a large protein foam.

[0068] (B): Sugar 1 in the addition of materials to the foam to the foam, and then adding the remaining sugar to continue to stir the wet foam. (Surmeted in the cake is critical, you must send the protein to the wet foam, that is, when the foam is pulled by the rubber scraper, the tip type is hanging but does not fall.)

[0069] (C): Add flour (sieve 2) a faster one-molded baking (160 ° C, 18 min), a cooling, a molded article. After the cake is determined by the cake volume (mL) / cake mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com