A Throat Nozzle Combined with Bubble Crushing and Target Impact

A bubble crushing and target-type technology, which is applied in cracking, catalytic cracking, injection devices, etc., can solve the problems of high oil pressure, atmospheric liquid, and less application, and achieve improved atomization performance, low gas-liquid ratio, and atomized particles even diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

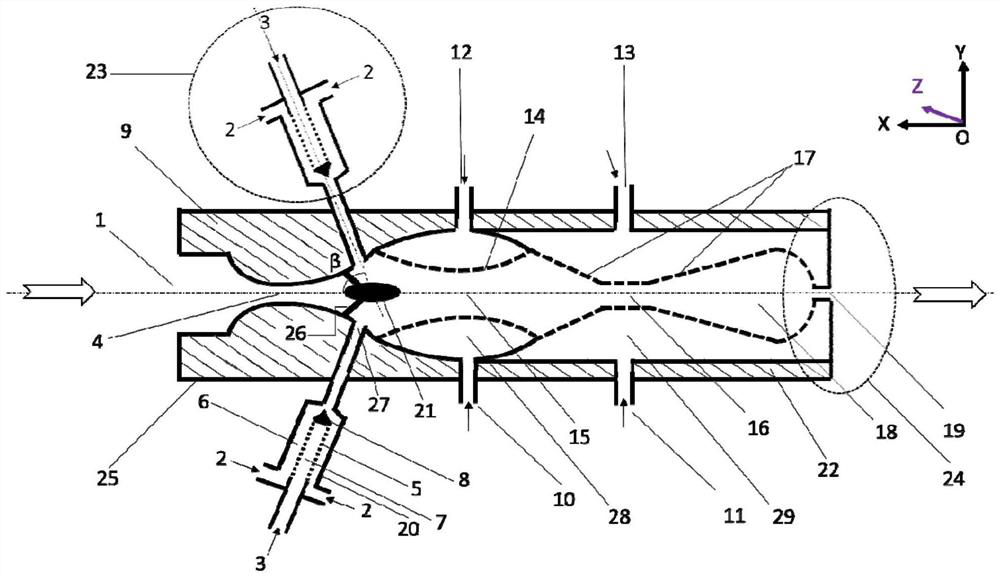

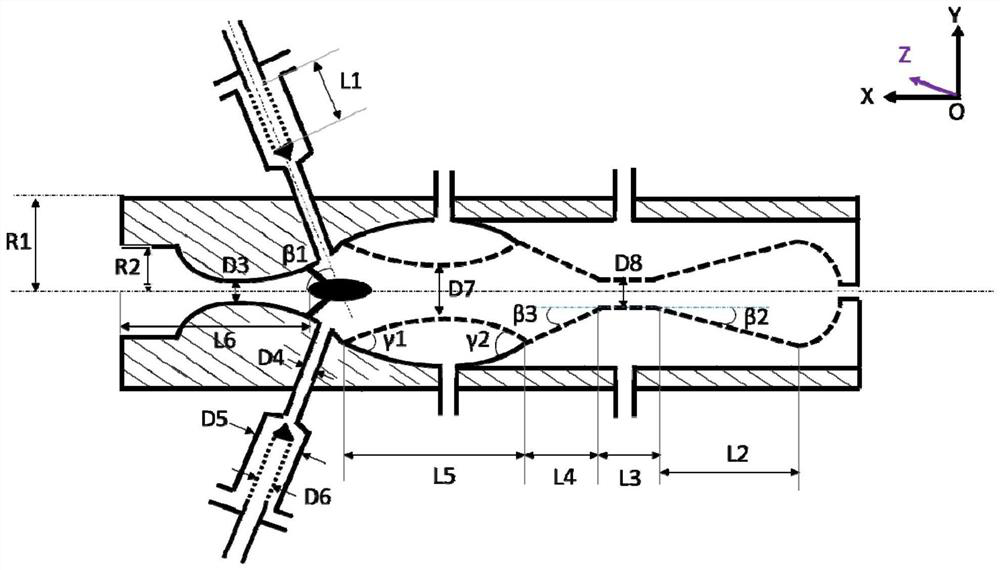

[0072] Daqing Crude Oil Atomization: A Throat Nozzle Combined with Bubble Breaking and Target Impact, such as figure 1 As shown, a certain flux of Daqing crude oil FLUX oil It is preheated to 220-250°C by an external device, pressurized by a high-pressure pump to about 10 atm, and sent to the nozzle inlet (2), and enters the outer chamber (6) to be mixed with water vapor. A certain amount of atomized superheated steam FLUX gas It is preheated to 250±20°C by an external device, pressurized by a compressor to about 10atm, and then sent to the steam inlet (3), then enters the inner chamber (7), and then flows out through the foamed porous tube wall (5), and in the tube The outer surface of the wall (5) is mixed with Daqing crude oil to form air bubbles. The bubble-like gas-liquid high-pressure mixed flow continues to flow along the outer cavity (6) to the outlet (27) of the gas-liquid microchannel mixer. Among them, the mass ratio of FLUX gas / FLUX oil =0.8, D5 is 14mm, D6 i...

Embodiment 2

[0083] No. 0 diesel oil atomization: Utilize the nozzle structure and parameters in Example 1, replace high-temperature crude oil with normal-temperature No. 0 diesel oil in Beijing, and replace high-temperature water vapor with normal-temperature air. Others are consistent with those in Example 1. Diesel mist droplets with an average particle size of 38 μm can be obtained, the droplet size is significantly reduced, the maximum particle size is 58 μm, and the particle size range is significantly narrowed.

Embodiment 3

[0088] No. 92 gasoline atomization: Utilize the nozzle structure and parameters in Example 1, replace high-temperature crude oil with No. 92 normal-temperature gasoline in the current Beijing area, and replace high-temperature water vapor with normal-temperature air. Others are consistent with those in Example 1. Gasoline mist droplets with an average particle size of 35 μm can be obtained, the droplet size is significantly reduced, the maximum particle size is 55 μm, and the particle size range is significantly narrowed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com