A scramjet combustion chamber support plate with right-angled triangular grooves

A right-angled triangle and scramming technology, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of poor fuel/oxidant mixing effect and poor fuel atomization performance, and achieve the promotion of fuel/oxidant mixing, high heat Load capacity, effect of improving spanwise distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

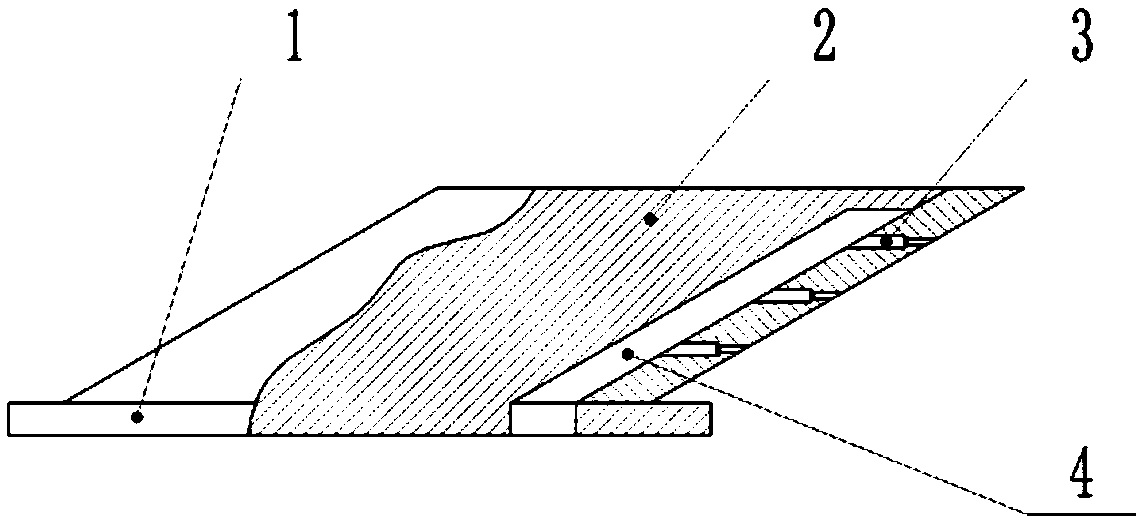

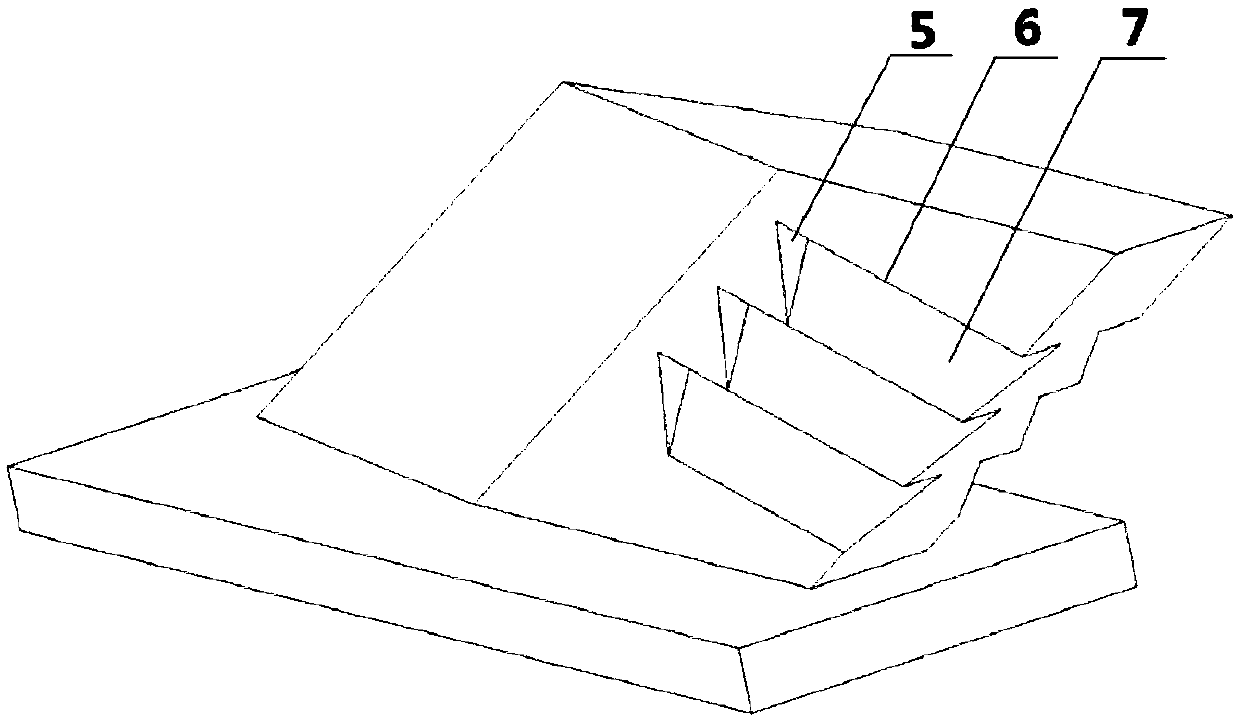

[0024] According to an embodiment of the present invention, for the traditional trailing edge spray strut (such as figure 1 shown) to improve the design (such as figure 2 shown). Compared with the traditional trailing edge spray support plate, the two sides of the support plate with right-angled triangular grooves have symmetrically arranged right-angled triangular groove structures 7, and the fuel injector 3 moves forward from the trailing edge to the top surface of the triangular groove 5 , the direction of the side edge 6 of the triangular groove and the direction 13 of fuel injection are parallel to the direction 12 of the airflow behind the front edge of the strut.

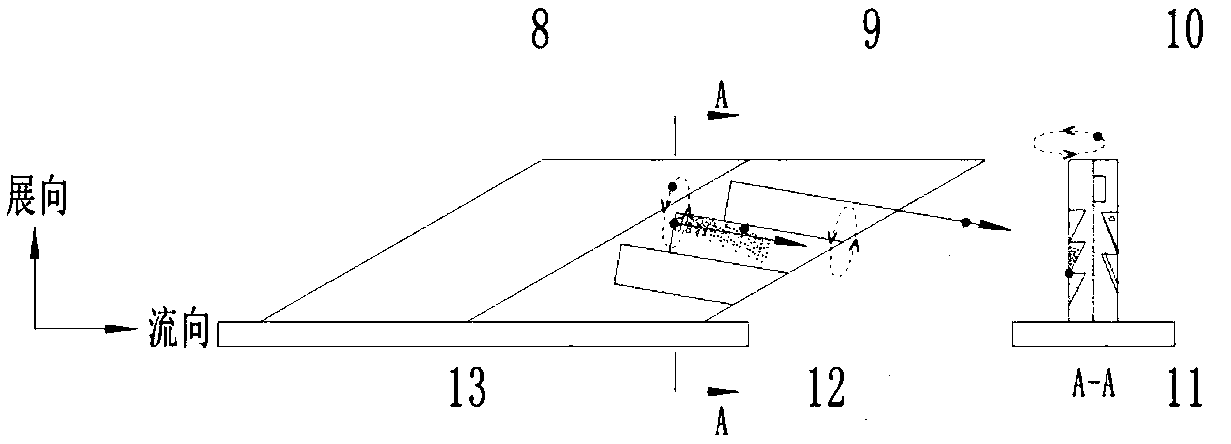

[0025] image 3 The working process of the support plate with right triangle groove is shown. Compared with the traditional trailing edge spraying branch plate, the branch plate arranges the fuel flow channel 4 at the sharp edge of the support plate, and the distance between the fuel 9 and the front edge ...

Embodiment 2

[0028] According to another embodiment of the present invention, the support plate with right-angled triangular groove (such as figure 2 Shown) further modified to achieve better results. Since the strength of the flow direction vortex 8 depends on the normal velocity difference of two adjacent airflows at the right angle junction 11 between the right triangle groove and the support plate, the symmetrically arranged right triangle grooves 7 on both sides of the support plate can be changed to staggered arrangement, and increase the normal depth of the right triangle groove 7 on the support plate, thereby improving the strength of the flow direction vortex 8. Compared with Embodiment 1, this modification introduces a stronger flow direction vortex, which can further improve the atomization performance of fuel and the mixing performance of fuel / oxidizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com