A rotary workbench for dismantling waste household appliances

A rotary and workbench technology, applied to workbenches, manufacturing tools, solid waste removal, etc., can solve problems such as inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

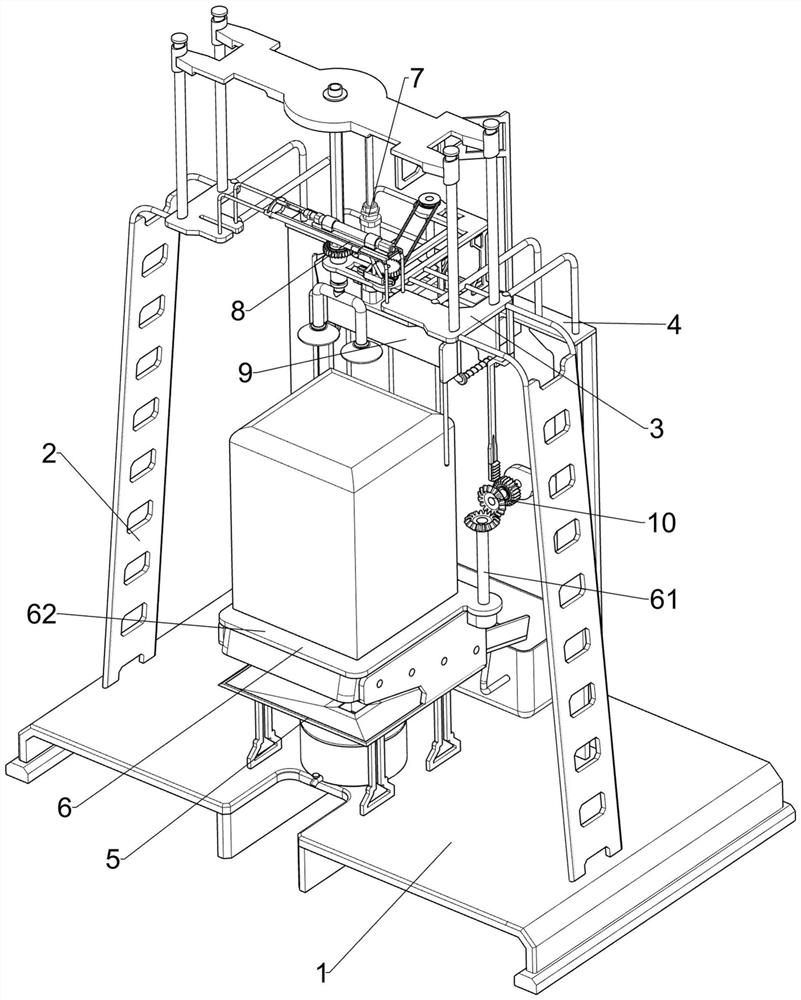

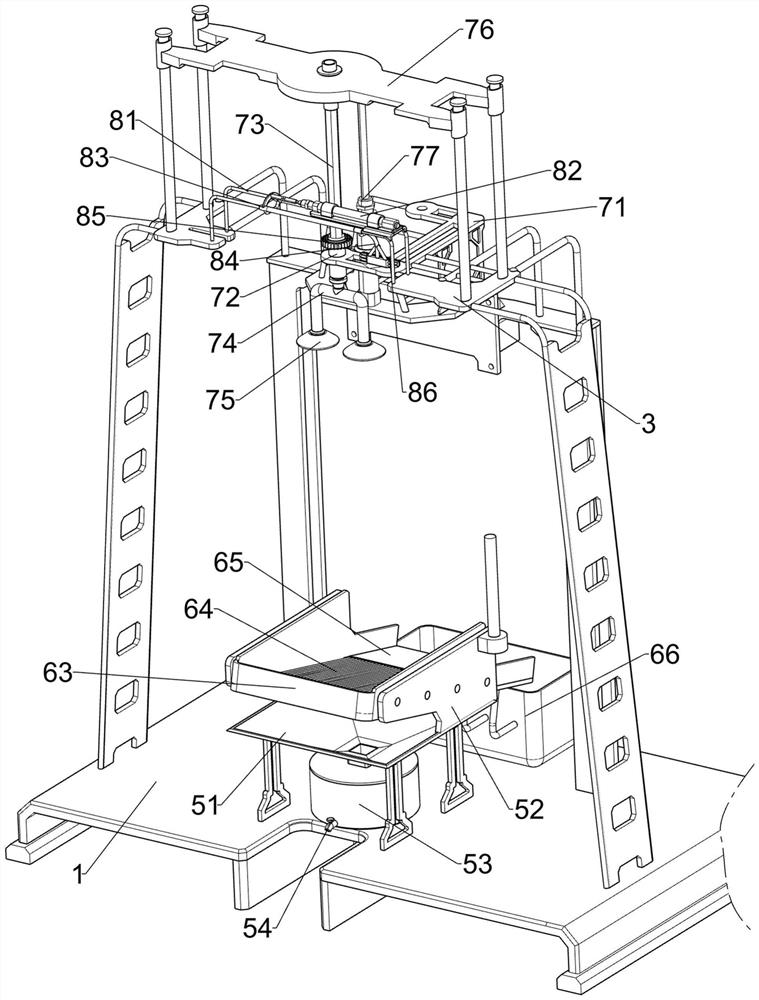

[0025] A rotary workbench for dismantling waste household appliances, such as Figure 1-2 As shown, it includes a base 1, a first bracket 2, a fixed plate 3 and a second bracket 4, the left and right sides of the top of the base 1 are connected with the first bracket 2, the first bracket 2 is connected with a fixed plate 3, the base A second bracket 4 is connected to the top rear side of the seat 1, and the second bracket 4 is connected to the fixed plate 3, and also includes a collection assembly 5, a screening assembly 6, a lifting assembly 7 and a rotating assembly 8, and the base 1 is provided with a collection assembly 5 A screening assembly 6 is provided between the base 1 and the collection assembly 5 , a lifting assembly 7 is provided between the second support 4 and the fixed plate 3 , and a rotating assembly 8 is provided between the lifting assembly 7 and the fixed plate 3 .

[0026] The collection assembly 5 includes a square funnel 51, a first mounting plate 52, a...

Embodiment 2

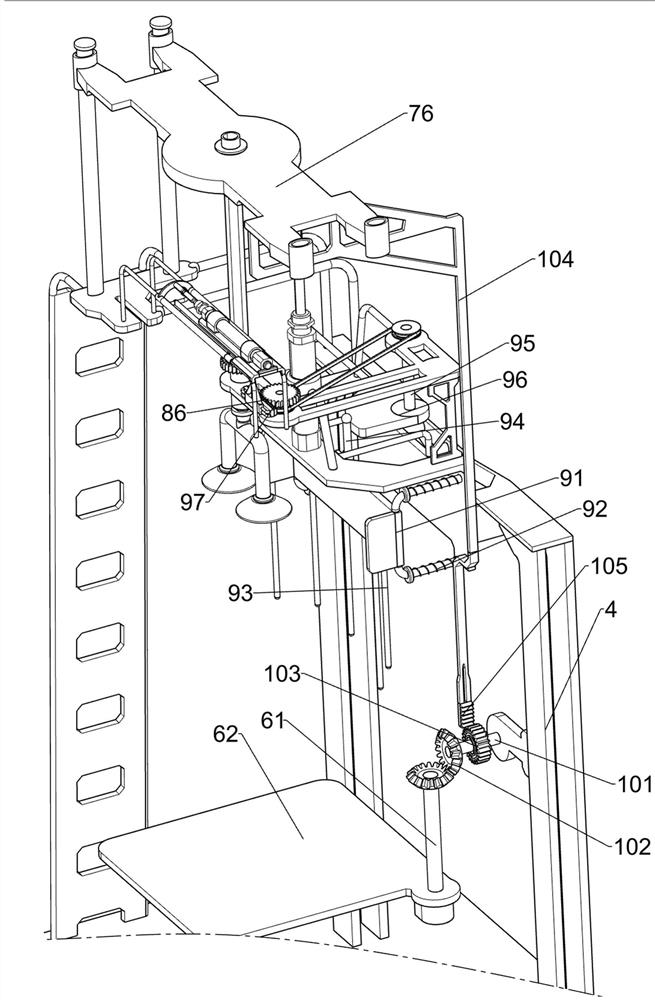

[0033] On the basis of Example 1, such as image 3 As shown, it also includes a limit assembly 9, the limit assembly 9 includes a sliding frame 91, a return spring 92, a limit rod 93, a contact rod 94, a first rotating shaft 95, a cam 96 and a transmission gear 97, on the second support 4 Slidingly connected with sliding frame 91, is connected with return spring 92 between sliding frame 91 and the second support 4, is connected with a plurality of limit rods 93 at the bottom of sliding frame 91, is connected with contact rod 94 at the top of sliding frame 91, and the second installation The plate 71 is rotatably connected with a first rotating shaft 95, the bottom of the first rotating shaft 95 is connected with a cam 96, the cam 96 cooperates with the contact rod 94, and the second mounting plate 71 is rotatably connected with a transmission gear 97, and the transmission shaft of the transmission gear 97 It is transmission connected with the first rotating shaft 95 , and the ...

Embodiment 3

[0036] On the basis of Example 2, such as image 3 As shown, the cover opening assembly 10 is also included. The cover opening assembly 10 includes a second rotating shaft 101, a bevel gear 102, a second one-way gear 103, a second connecting frame 104 and a transmission rack 105, and the middle part of the second bracket 4 rotates. The second rotating shaft 101 is connected with the second rotating shaft 101, the second rotating shaft 101 and the shaft rod 61 are connected with a bevel gear 102, the two bevel gears 102 mesh with each other, the second rotating shaft 101 is connected with a second one-way gear 103, and the slide plate 76 is connected with There is a second connecting frame 104 , and a transmission rack 105 is connected to the second connecting frame 104 , and the transmission rack 105 will mesh with the second one-way gear 103 .

[0037] When the slide plate 76 moves up and down, the second connecting frame 104 drives the transmission rack 105 to move up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com