Horizontal warehouse bulk grain warehousing and distributing method

A technology of bungalow warehouses and grain distribution vehicles, which is applied in loading/unloading, conveyors, transportation and packaging, etc. It can solve the problems of long time, troublesome and low efficiency of grain distribution, so as to reduce the number of movements and ensure reliable supply The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

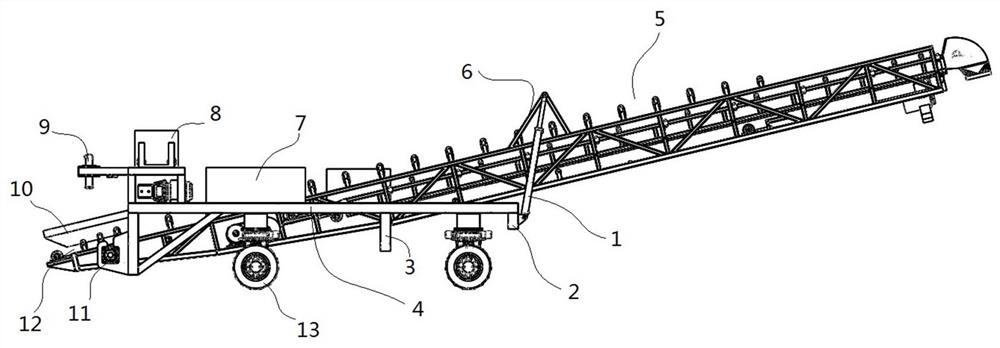

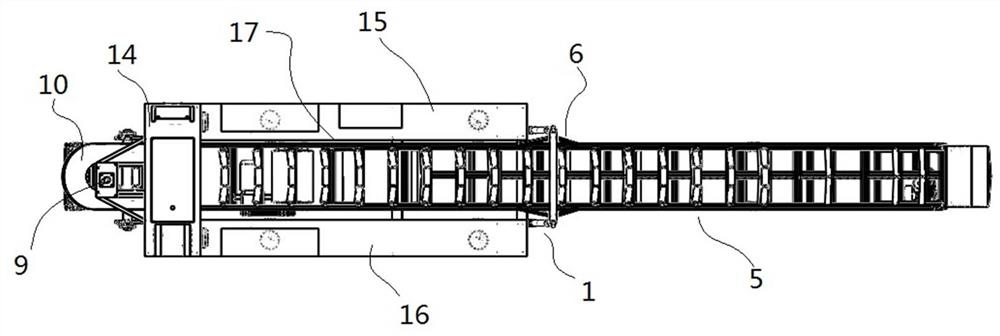

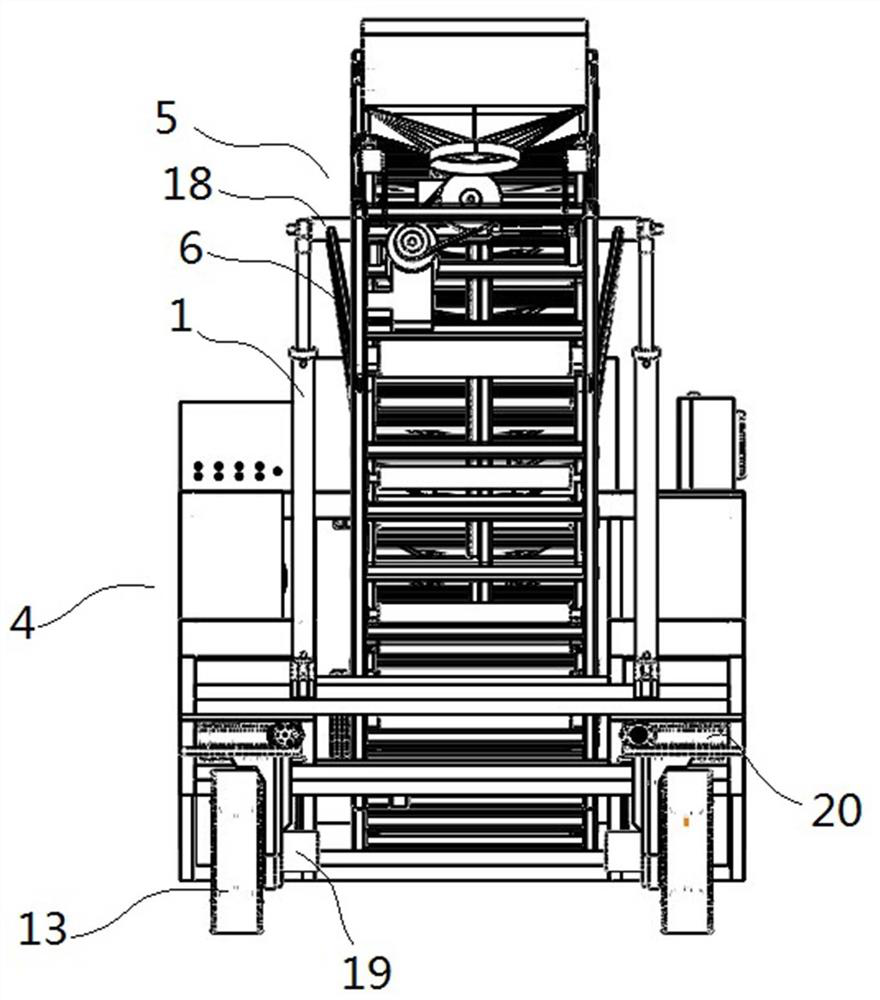

[0027] Embodiment 1 of the method for distributing grain into the warehouse for loose grain in the bungalow warehouse of the present invention is as follows: Figure 1~8 Shown: In the process of distributing grain to the granary, the grain distributing equipment inside the granary and the grain distributing equipment outside the granary are used. The granary in this embodiment is a square granary, and the length of the square granary is longer than the length of the width direction.

[0028] The grain distributing equipment in the granary comprises the second grain conveyor 32, the first grain conveyor 34 and the grain distributing vehicle 35 arranged sequentially along the grain conveying direction, and the grain distributing equipment outside the granary comprises at least one grain conveyor, which is used to transport the grain on the vehicle The grain is transported to the feed end of the second grain conveyor. In this embodiment, each grain conveyor is a belt conveyor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com