Automatic iron phosphate production device and method thereof

A production device and technology of iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low degree of automation, improved product quality, unfavorable production control, etc., to reduce production costs, improve production efficiency, Conducive to the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

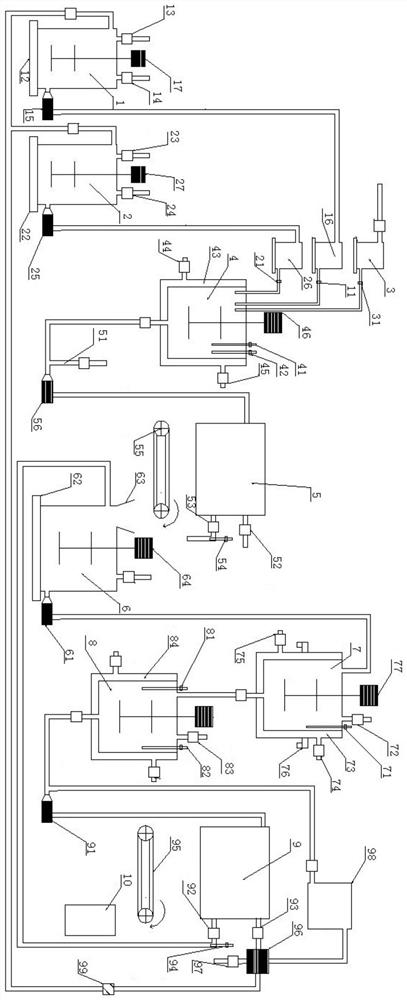

[0043] Such as figure 1 Shown is the embodiment of the ferric phosphate automatic production device of the present invention, comprises phosphorus salt dissolving tank 1, iron salt dissolving tank 2, hydrogen peroxide metering tank 3, reaction kettle 4 that the first pH meter 41 is installed, the first filter press 5. Dispersion kettle 6, primary aging kettle 7 with first thermometer 71 installed, secondary aging kettle 8 with second pH meter 81 and second thermometer 82 and second filter press 9:

[0044] The phosphorus salt dissolving tank 1, the iron salt dissolving tank 2, and the hydrogen peroxide metering tank 3 communicate with the reactor 4 through the first flow pump 11, the second flow pump 21, and the third flow pump 31 respectively; the measuring end of the first pH meter 41 extends Enter below the liquid level of reactor 4, the bottom of reactor 4 communicates with the first filter press 5 by the first washing pump 56;

[0045] The first filter press 5 is connect...

Embodiment 2

[0068] The embodiment of the production method of a kind of ferric phosphate automatic production device of present embodiment embodiment, comprises the following steps:

[0069] S10. Add ferrous sulfate heptahydrate into the iron salt dissolving tank 2, add diammonium phosphate into the phosphate salt dissolving tank 1, prepare ferrous sulfate solution and diammonium phosphate solution with preset concentrations, and transfer them quantitatively to the reaction Still 4, and add the hydrogen peroxide of setting weight in the reaction kettle 4, react to obtain the amorphous slurry;

[0070] S20. The amorphous slurry in step S10 enters the first filter press 5 for pressure filtration to obtain the first filter cake, and the first filter cake falls into the dispersion kettle 6 for dispersion to obtain the dispersed slurry;

[0071] S30. The dispersed slurry in step S20 is transferred to the primary aging tank 7 for aging to obtain a monoclinic ferric phosphate dihydrate slurry; ...

specific Embodiment approach

[0076] After setting the parameters of the batching, reaction and aging equipment, the DCS control system measures the weight of the secondary mother liquor in the iron salt dissolving tank 2 according to the iron salt second weighbridge 22, and opens the iron salt feeding pipeline 23 pneumatic electromagnetic Add 461kg of ferrous sulfate heptahydrate into the ferrous salt dissolving tank 2, and then open the ferric salt dissolving tank 2 ferrous salt mixing mechanism to prepare 1685 kg of ferrous sulfate solution with a pre-set iron content of 5.5%. The DCS control system is based on the first Weighbridge 12 measures the weight of the secondary mother liquor in the phosphate salt dissolving tank as 1157kg. Open the phosphate salt feeding pipeline 13 solenoid valve and add 220kg of ferrous sulfate heptahydrate into the phosphate salt dissolving tank 1, and prepare after opening the phosphate salt stirring mechanism. 1377kg of diammonium phosphate solution with a phosphorus cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap