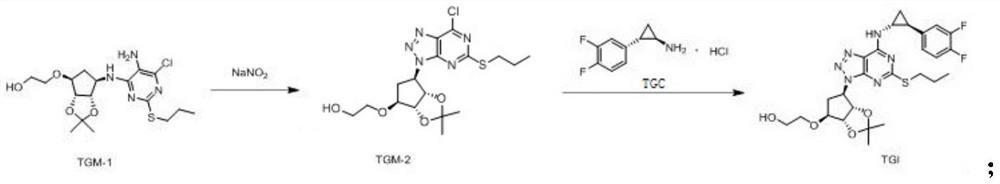

A kind of method of applying continuous flow reaction technology to prepare advanced intermediate of ticagrelor

A technology for ticagrelor and intermediates, applied in the field of compound synthesis, can solve problems such as unsatisfactory synthesis efficiency and immature synthesis process, and achieve the effects of no amplification effect, convenient real-time monitoring, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

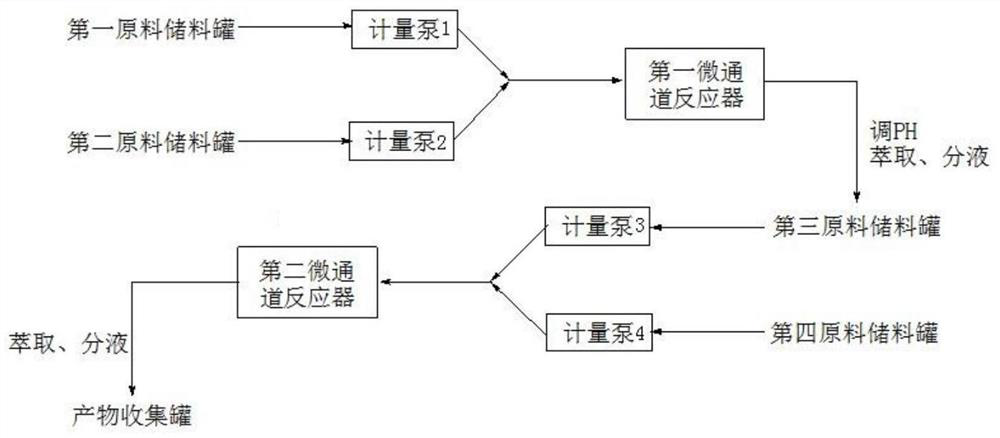

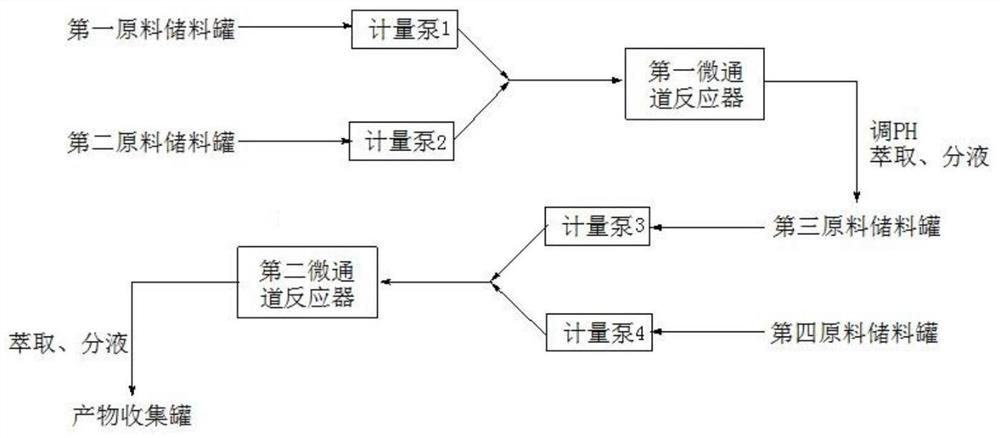

Method used

Image

Examples

Embodiment 1

[0036] 1) Preparation of TGM-2:

[0037] Weigh 20g of TGM-1 (0.048mol, 1.0eq), 5.1g of concentrated hydrochloric acid (0.05mol, 1.05eq), measure 120mL of tetrahydrofuran and put it in the first raw material storage tank, stir evenly, as the first material;

[0038] Weigh 3.5g of sodium nitrite (0.05mol, 1.05eq), measure 50mL of water, place in the second raw material storage tank, stir evenly, and use it as the second material.

[0039] The temperature of the first microchannel reactor is controlled at 25-30°C through the high and low temperature integrated machine, and the first material is pumped into the first microchannel reactor through the metering pump 1 at a flow rate of 3mL / min; the second material Pump into the first microchannel reactor through the metering pump 2, and the pumping flow rate is 2mL / min. The diazotization and cyclization reactions were carried out in the first microchannel reactor, the reaction time was 10 min, and the reaction temperature was 28°C. ...

Embodiment 2

[0045] 1) Preparation of TGM-2:

[0046] Weigh 30g of TGM-1 (0.071mol, 1.0eq), measure 8.7mL of 9N sulfuric acid (0.078mol, 1.1eq), place 120mL of ethanol in the storage tank of the first raw material, stir well, and use it as the first material;

[0047] Weigh 5.4g of sodium nitrite (0.078mol, 1.1eq), measure 160mL of water, place in the second raw material storage tank, stir evenly, and use it as the second material.

[0048] The temperature of the first microchannel reactor is controlled at 25-30°C through the high and low temperature integrated machine, and the first material is pumped into the first microchannel reactor through the metering pump 1, and the pumping flow rate is 5mL / min; the second material Pump into the first microchannel reactor through the metering pump 2, and the pumping flow rate is 4 mL / min. The diazotization and cyclization reactions were carried out in the first microchannel reactor, the reaction time was 6 min, and the reaction temperature was 30°C....

Embodiment 3

[0054] 1) Preparation of TGM-2:

[0055] Weigh 50g of TGM-1 (0.12mol, 1.0eq), 18g of glacial acetic acid (0.3mol, 2.5eq), measure 300mL of tetrahydrofuran into the first raw material storage tank, stir evenly, and use it as the first material;

[0056] Weigh 10.7g of sodium nitrite (0.16mol, 1.3eq), measure 200mL of water, place in the second raw material storage tank, stir evenly, and use it as the second material.

[0057] The temperature of the first microchannel reactor is controlled at 25-30°C through the high and low temperature integrated machine, and the first material is pumped into the first microchannel reactor through the metering pump 1, and the pumping flow rate is 8mL / min; the second material Pump into the first microchannel reactor through the metering pump 2, and the pumping flow rate is 6mL / min. The diazotization and cyclization reactions were carried out in the first microchannel reactor, the reaction time was 4 min, and the reaction temperature was 32°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com