Heating medium heating system for spinning production

A heating system and spinning technology, which is applied in the heat treatment of artificial filaments, etc., can solve the problems of short discharge cycle and large melt temperature fluctuations, and achieve the effects of extending the discharge cycle, cooling time and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

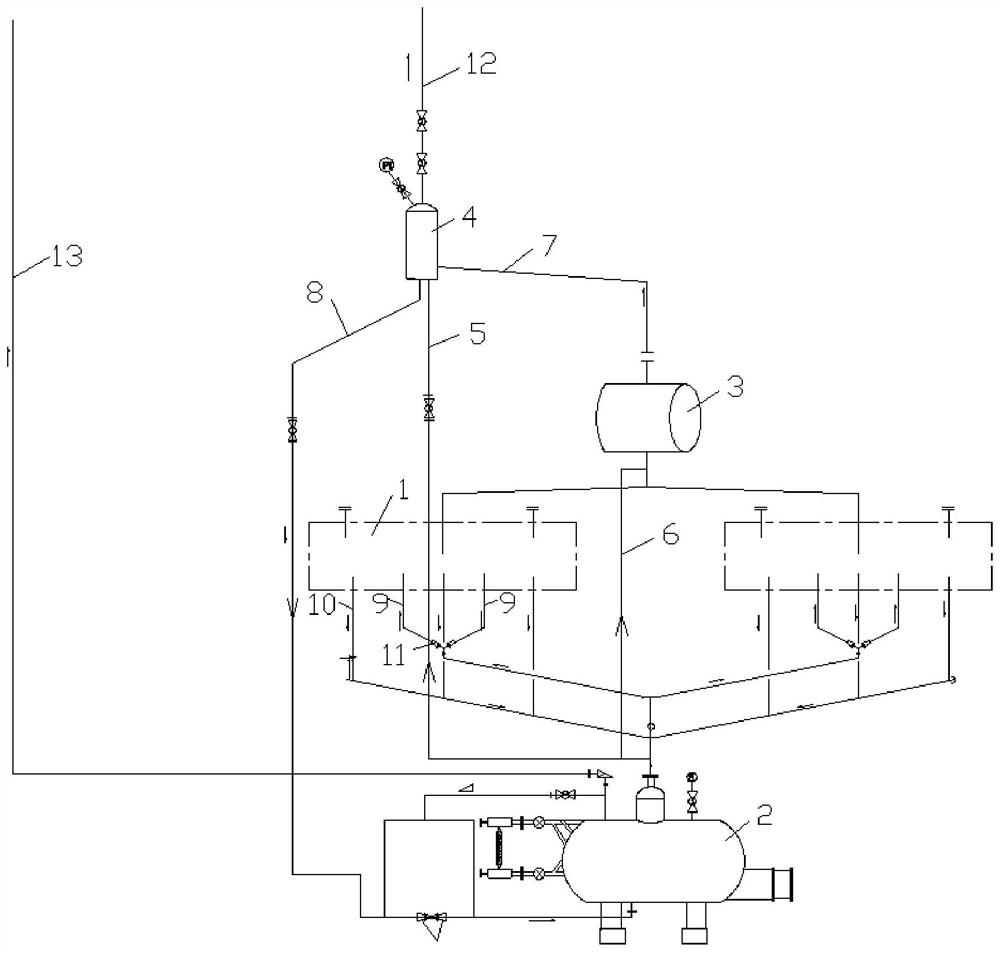

[0018] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

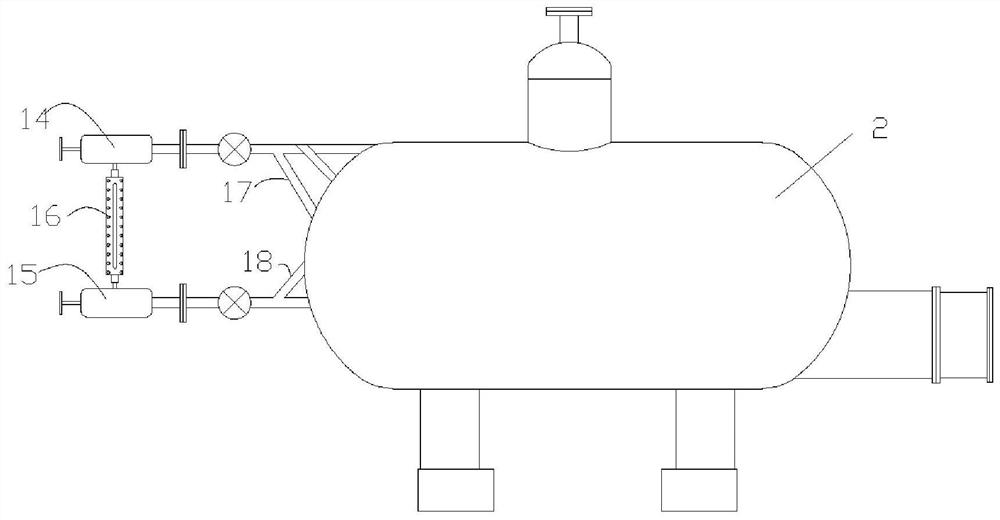

[0019] Such as figure 1 with 2 As shown, the present invention provides a thermal media heating system produced by spinning, including at least one spinning box 1, a heat medium heater 2, and a screw extruder 3, further comprising a discharge tank 4, a first intake pipe 5, The second intake pipe 6, the intake pipe 7, and the return pipe 8, the first intake pipe 5 is connected to the heat port of the heat medium heater 2, and the first intake pipe 5 is connected to the bottom of the discharge tank 4, The intermediate portion of the first intake pipe 5 penetrates through the spinning box 1, and the second intake pipe 6 is connected to the heat port of the heat medium heater 2, the second intake pipe 6 and the screw extruder 3 Connectation, the two ends of the intake pipe 7 communicate the screw extruder 3 and the side surface of the discharge tank 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com