Devicefor improving washing quality of cold-rolling strip steel surface

A technology for surface cleaning and cold-rolling strip steel, which is applied in the electrolysis process and electrolysis components to achieve the effect of improving the cleaning quality, prolonging the discharge period and maintaining the purity of water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

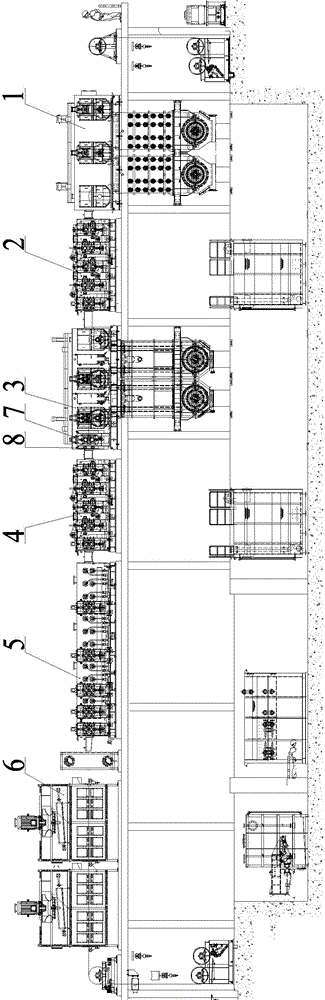

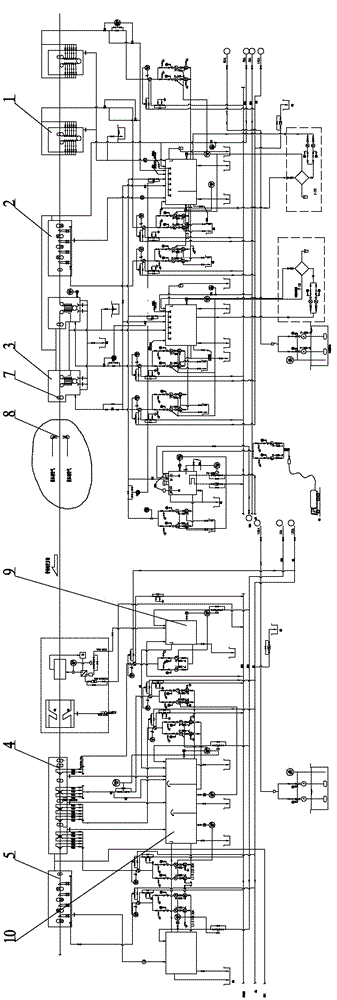

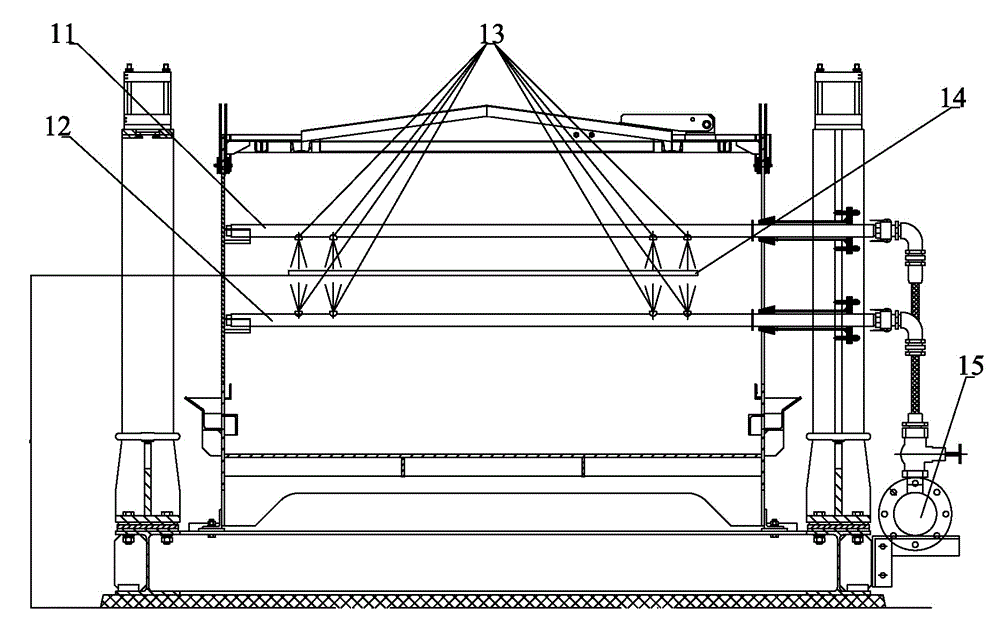

[0016] Such as Figure 1-Figure 3 As shown, it is a device for improving the surface cleaning quality of cold-rolled strip steel in the present invention, including an alkali washing device 1, an alkali scrubbing device 2, an electrolysis device 3, a water scrubbing device 4, and a water rinsing device 5 along the running direction of the strip steel , Drying device 6, between the outlet of the squeeze roller 7 of the electrolysis device 3 and the inlet of the water scrubbing device 4, a purging device 8 is provided.

[0017] The purging device 8 comprises an upper purge beam 11 and a lower purge beam 12, a nozzle 13 for blowing out compressed air is provided between the upper purge beam 11 and the lower purge beam 12, and the nozzle 13 is also connected with a compressed air supervisor15.

[0018] The process for improving the surface cleaning quality of cold-rolled strip steel in the present invention comprises steps as follows: alkali washing, alkali scrubbing, electrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com