Centralized water supply and gas supply system and method for mud suction sinking construction of large open caisson

A gas supply system and caisson technology, which is applied in pipeline systems, caissons, infrastructure engineering, etc., can solve problems affecting work efficiency, delaying project progress, and high water and gas supply requirements, so as to achieve high work efficiency and ensure water and gas supply , Improve the effect of mud suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

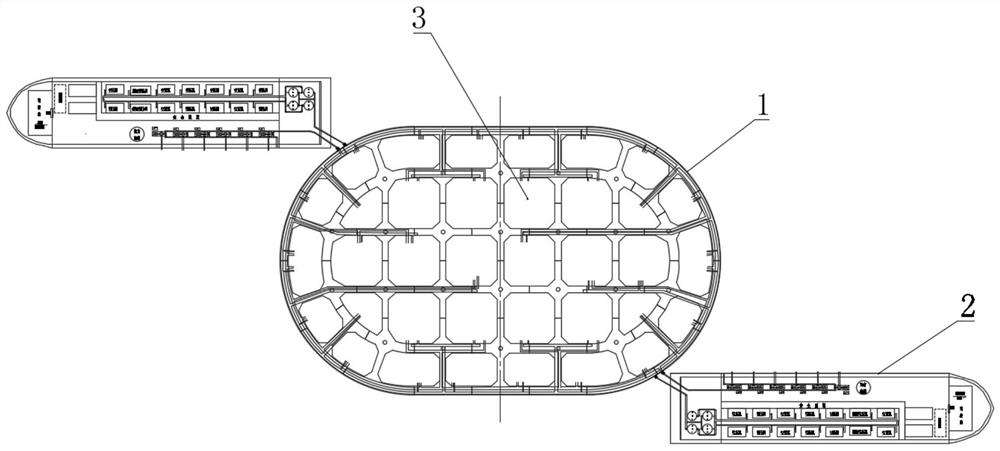

[0043] Such as figure 1 As shown, in this embodiment, a centralized water supply and gas supply system for large-scale caisson suction mud sinking construction is specifically provided, aiming at ensuring the stability of the water supply and gas supply system and the smooth progress of the caisson sinking construction site. The gas system includes: caisson platform 1, water supply and gas supply pipe group, and water and gas supply assembly. The specific design is as follows:

[0044] ①Water supply and air supply pipe group

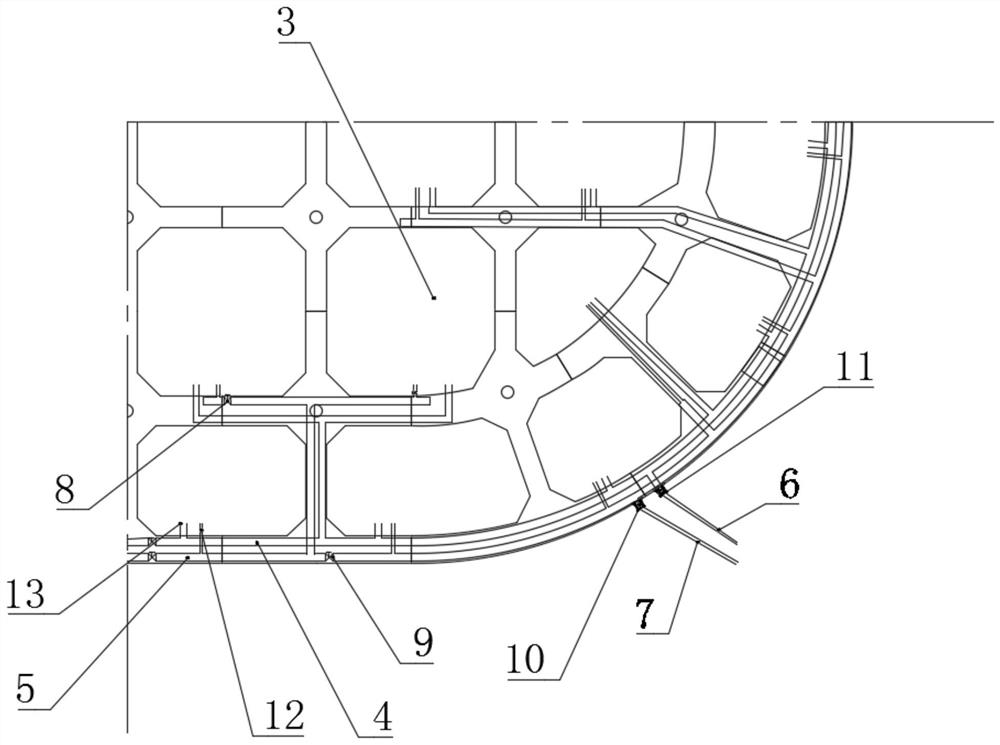

[0045] Such as figure 2 As shown, in this embodiment, the caisson platform 1 is divided into two regions, and the two regions are respectively provided with water supply and gas supply pipe groups, so as to realize that each of the water supply and gas supply pipe groups is respectively arranged on the division of the caisson platform 1 in different regions.

[0046] The water supply and gas supply pipe group includes a water supply main pipe 4 and a g...

Embodiment 2

[0073] On the basis of the centralized water supply and gas supply system for large caisson suction mud sinking construction provided in the above-mentioned embodiment 1, a centralized water supply system for large caisson suction mud sinking construction is specifically provided in this embodiment. gas method, which includes:

[0074] S1: The caisson platform 1 is divided into two areas, and the nozzles of the water supply and gas supply pipe groups in the two areas are respectively arranged at the opposite corners of the caisson platform 1 .

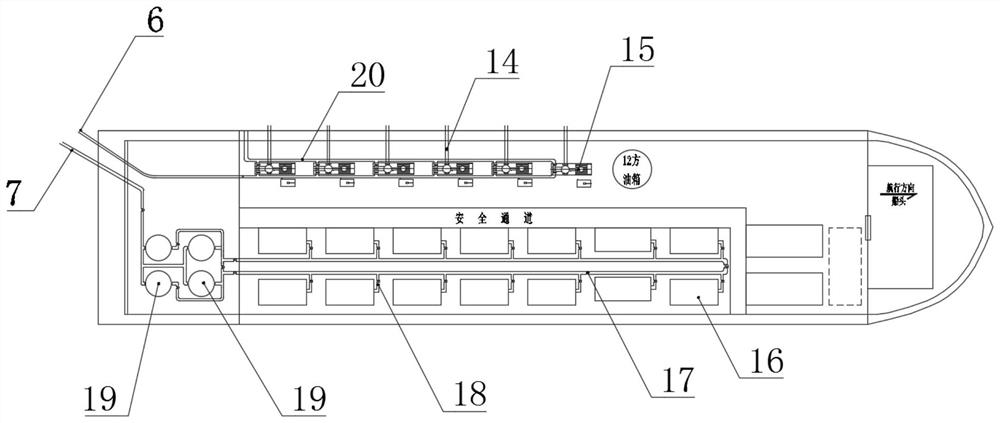

[0075] S2: The nozzles of each water supply and air supply pipe group are respectively connected to the corresponding water supply and air supply assembly, and the water supply and air supply assembly is turned on for water and air supply; The assembly supplies water and air.

[0076] S3: After the installation of the water supply and air supply assembly on the multifunctional ship 2 is completed, the high-pressure water and high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com