Novel hidden spring hinge

A spring hinge and concealed technology, which is applied to hinges with pins, door/window accessories, wing leaf parts, etc., can solve the problems of insufficient power, poor machining accuracy, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

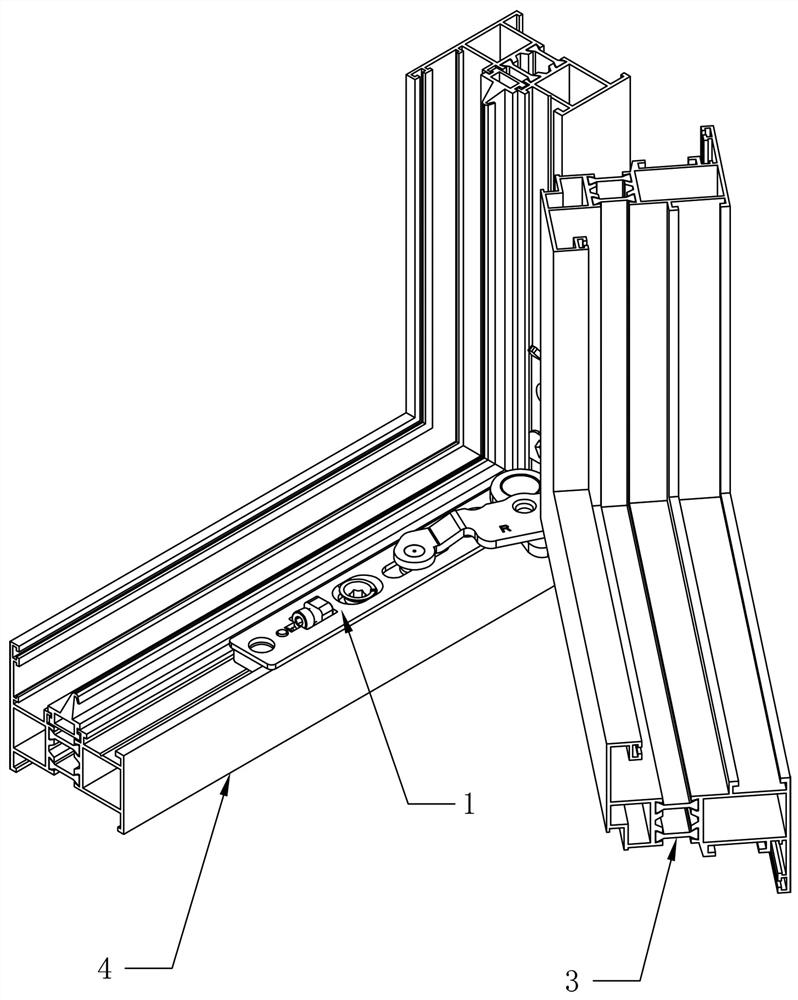

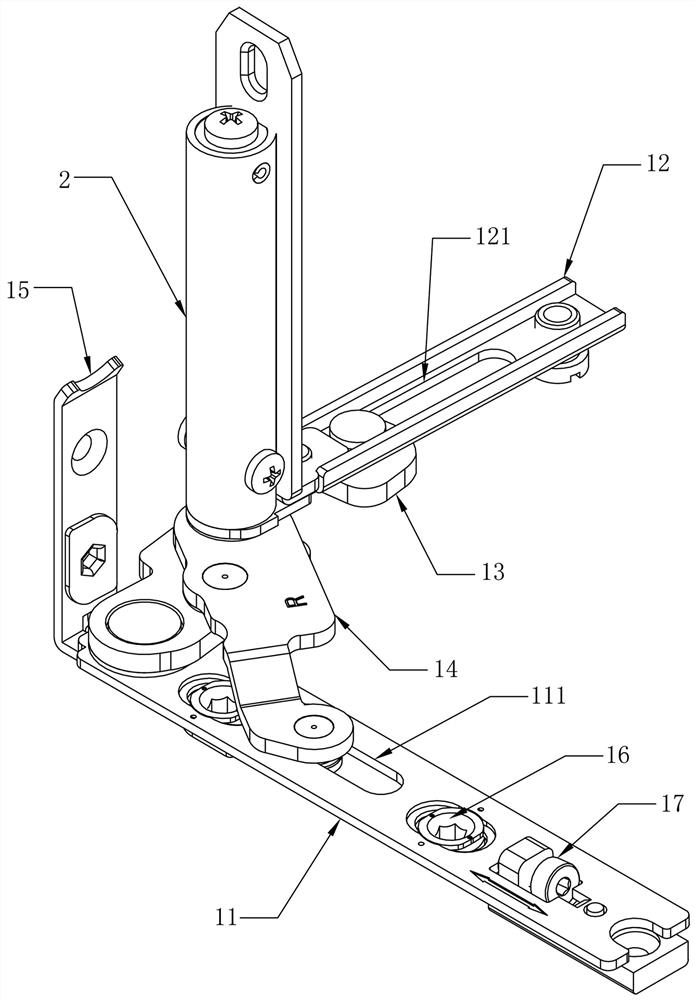

[0020] see Figure 1 to Figure 6 As shown, a new hidden spring hinge in this embodiment includes a hinge 1 and a driving part 2 that drives the hinge 1 to close.

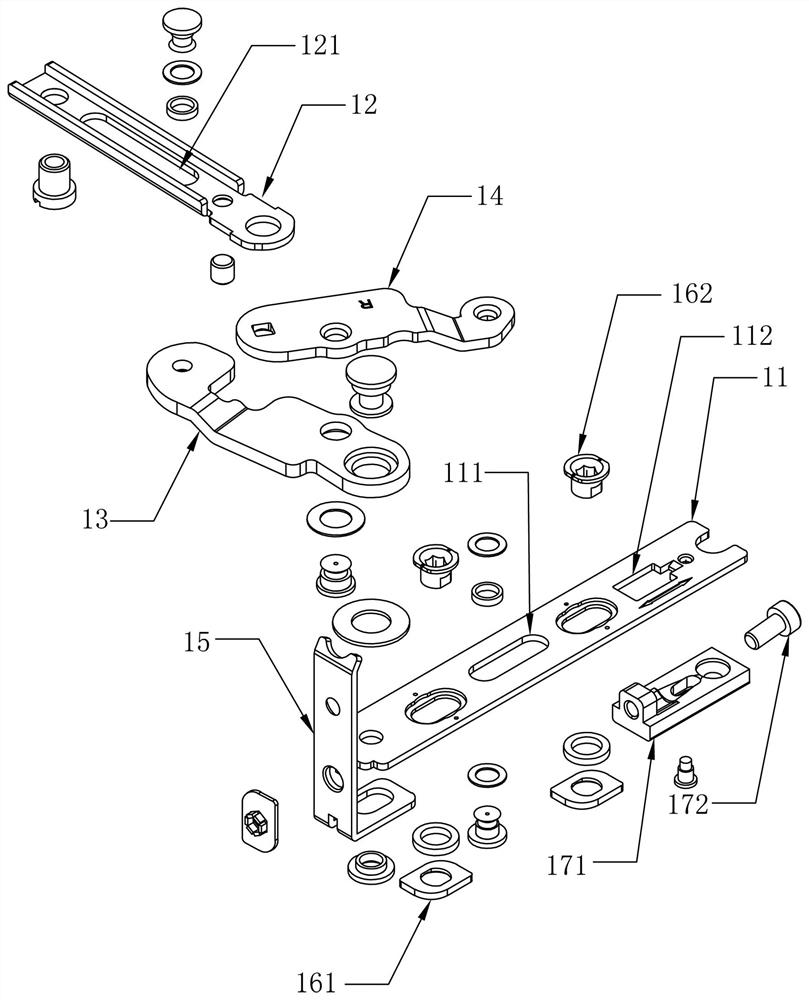

[0021] The hinge 1 includes a frame connecting piece 11 connected with the profile of the window frame 4 , a fan connecting piece 12 connected with the window sash 3 , a first connecting rod 13 , and a second connecting rod 14 . The frame connector 11 is formed with a first chute 111, the fan connector 12 is formed with a second chute 121, one end of the first connecting rod 13 is pivotally connected with the frame connector 11, and the first The other end of the connecting rod 13 is slidingly fitted with the second slide groove 121, and one end of the second connecting rod 14 is pivotally connected with the fan connector 12 and the first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com