Gas conveying equipment for metallurgical machinery

A technology of conveying equipment and gas conveyor, which is applied in the direction of mechanical equipment, gas/liquid distribution and storage, non-detachable pipe connection, etc., and can solve the hidden dangers of equipment aging, valve body corrosion and perforation, suction and exhaust at pipe body connections and other issues, to achieve the effect of strengthening the sealing, strengthening the fastening, and avoiding large-scale explosion and combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

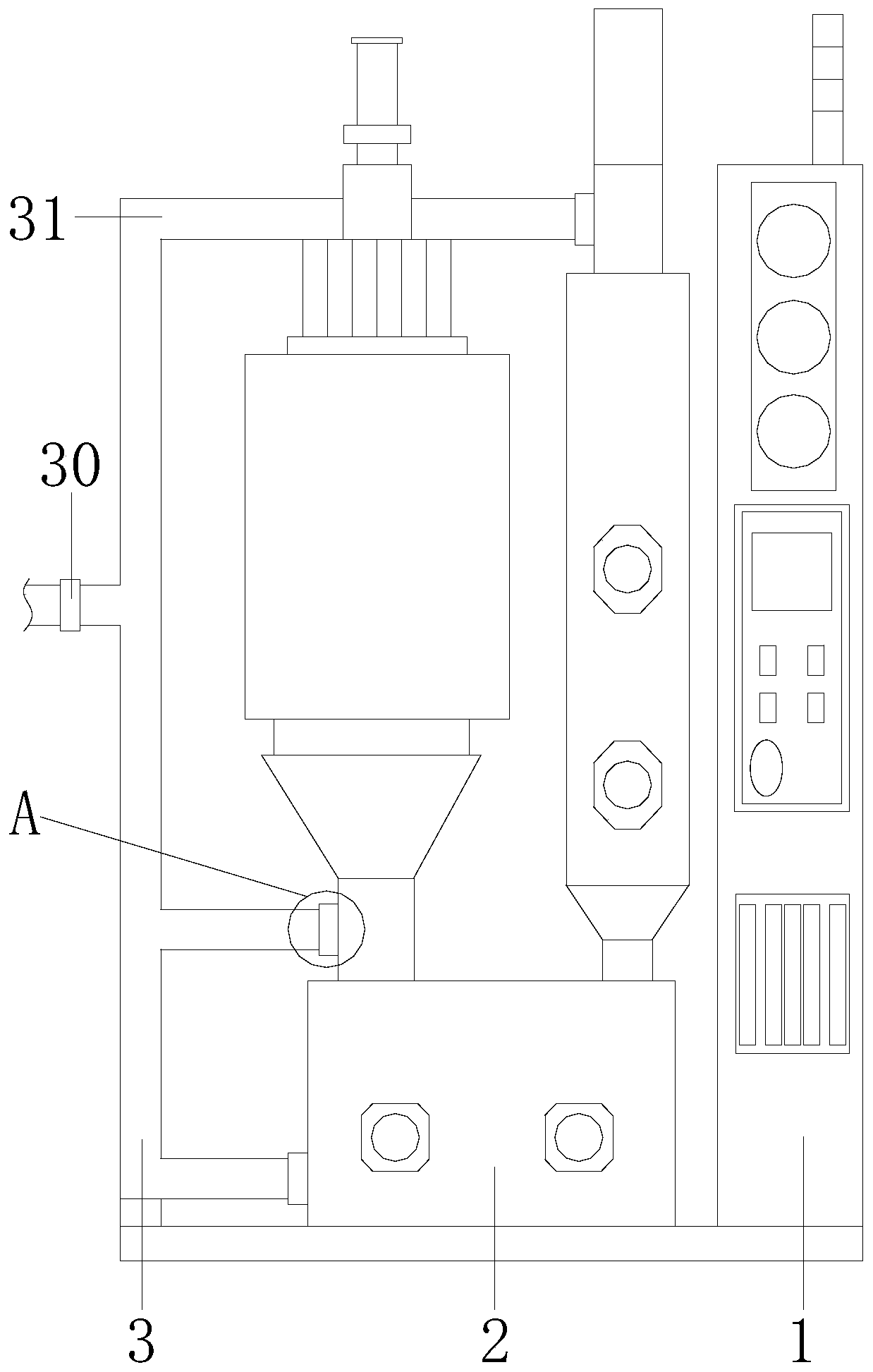

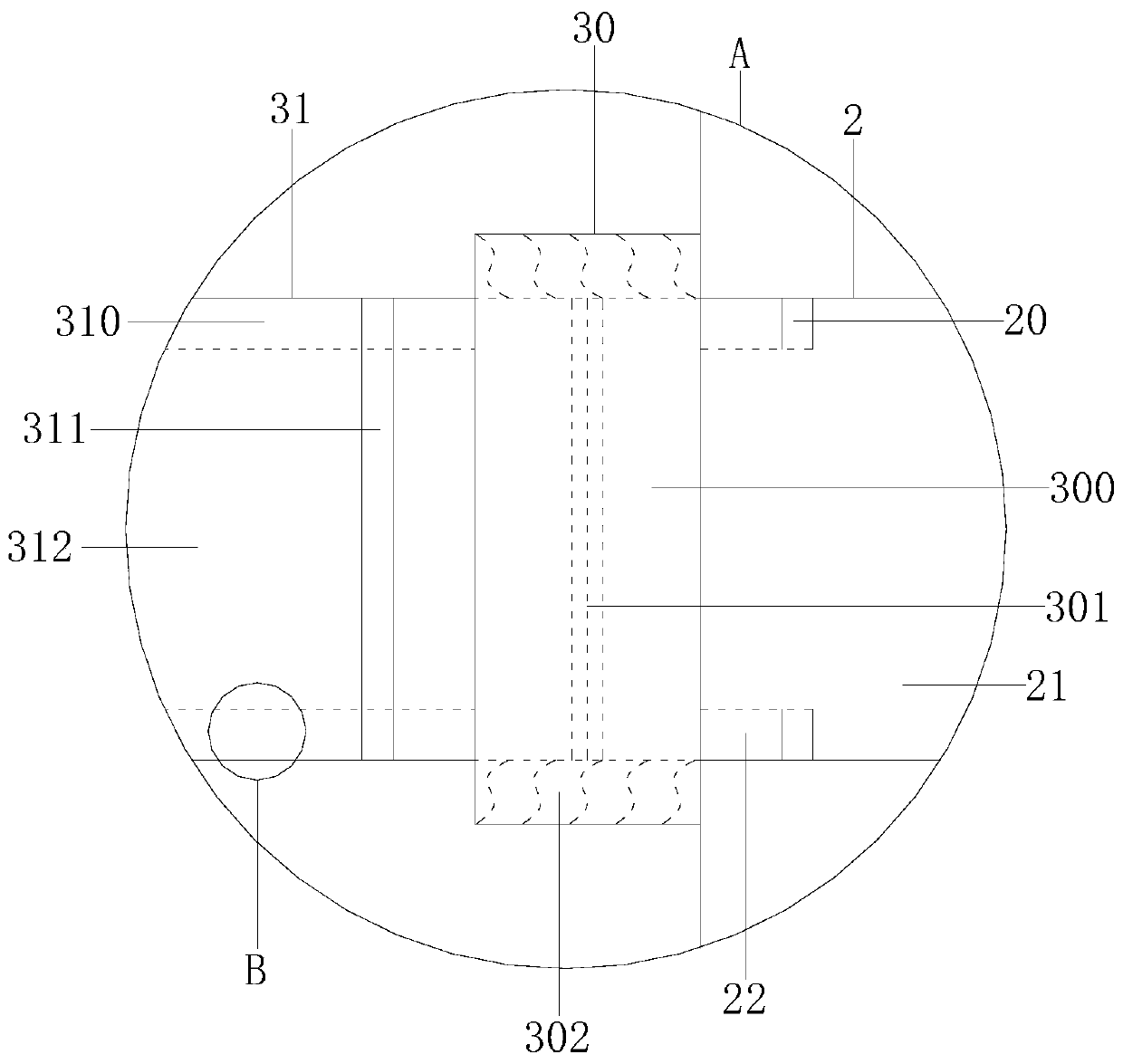

[0026] see Figure 1-4 , the present invention provides a technical solution for gas conveying equipment for metallurgical machinery: its structure includes a console 1, a gas conveying machine 2, and a gas conveying pipe 3, the console 1 is locked with the gas conveying machine 2 and the two are electrically connected, The gas conveyor 2 is installed and connected to the gas delivery pipe 3. The gas conveyor 2 is composed of a gas storage fastener 20, a gas storage machine 21, and a gas storage limit groove 22. The gas storage fastener 20 is installed On the gas storage machine 21, the gas storage fastener 20 is equipped with a gas storage limit groove 22, and the gas delivery pipe 3 includes a pipeline swivel 30 and a pipeline 31, and the pipeline swivel 30 is embedded with the pipeline 31. The pipe swivel 30 is fitted with the pipe 31, and the thread design strengthens the fastness of the two. The pipe swivel 30 includes a swivel 300, a swivel groove 301, and a helical stru...

Embodiment 2

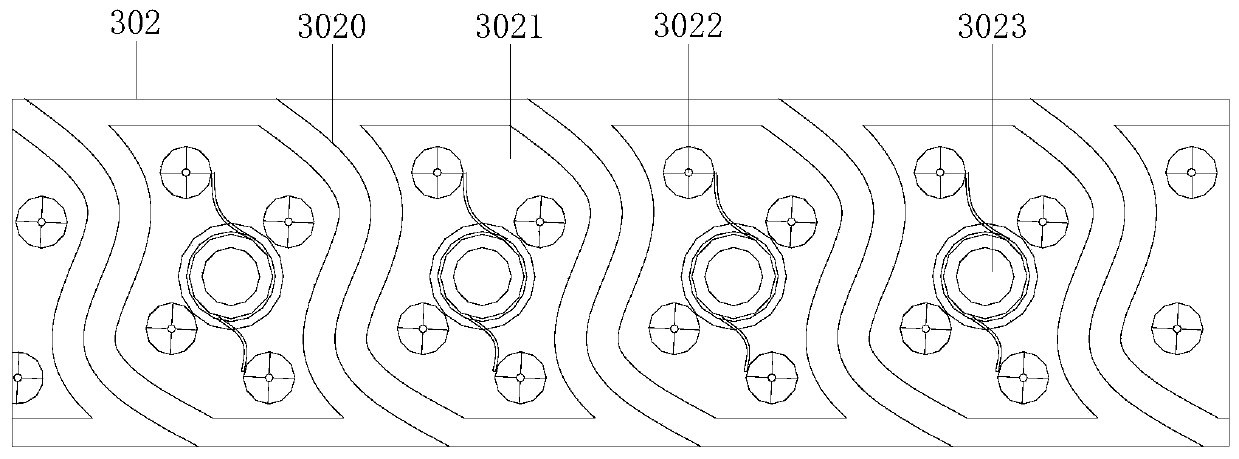

[0029] see Figure 5-6, the present invention provides a technical solution for gas conveying equipment for metallurgical machinery: the pipe side device 310 in its structure includes a support rod 3100, a stacking device 3101, an upper plate 3102, a middle plate 3103, a bottom plate 3104, and a main steel layer 3105, the tube layer of the tube side device 310 is relatively thick, and the multi-layer steel layer is protected when hammering, the support rod 3100 is installed and connected with the upper plate 3102, the middle plate 3103, and the bottom plate 3104, and the stacker 3101 Installed on the middle plate 3103, the stacker 3101 not only plays the role of driving but also plays the role of support and reinforcement, the bottom plate 3104 is welded with the main steel layer 3105, and the stacker 3101 includes a transmission stack Rod 500, fitting swivel 501, fastening groove 502, fitting plate 503, transmission round shaft 504, described transmission stacking rod 500 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com