A built-in partition type storage tank

A clapboard type and storage tank technology, applied in the direction of jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of unfavorable control trim, complex connection system design, small pipeline diameter, etc., and achieve simplified series-parallel design , Reduce system complexity, reduce the effect of design complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with embodiment.

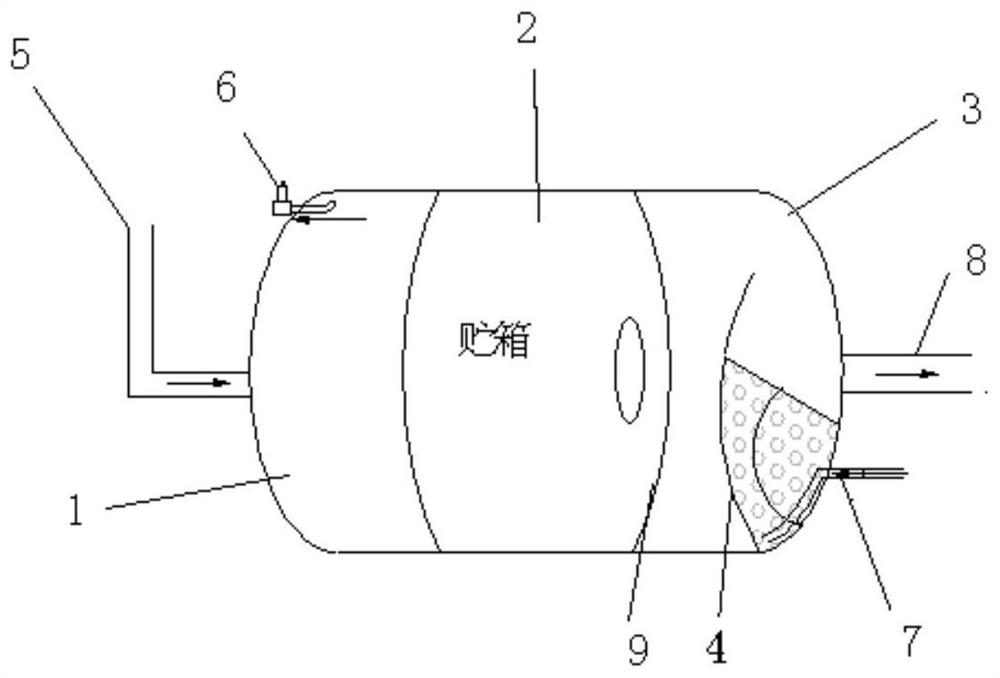

[0027] A built-in bulkhead storage tank, such as figure 1 As shown, it includes the front ellipsoid bottom, the cylinder section and the rear ellipsoid bottom, the front ellipsoid bottom and the rear ellipsoid bottom are connected with the cylinder section in the middle, and the three form a storage tank;

[0028] There are anti-shake plates and partitions inside the storage tank;

[0029] The anti-sway plate is an annular plate, which is installed on the inner wall of the cylinder section to prevent the propellant from shaking when the tank is full;

[0030] The partition is of partial spherical configuration, and is connected with the anti-sway plate adjacent to the bottom of the rear ellipsoid through screw connection, and the height of the partition is higher than the width of the anti-sway plate;

[0031] The propellant is injected through the filling pipeline at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com