Machining detection equipment for automobile hub

A technology for testing equipment and automotive hubs, applied in image data processing, instruments, electrical transmission signal systems, etc., can solve problems such as differences in detection quality, processing effects, and backward detection methods, and achieve detection, improve effectiveness, and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

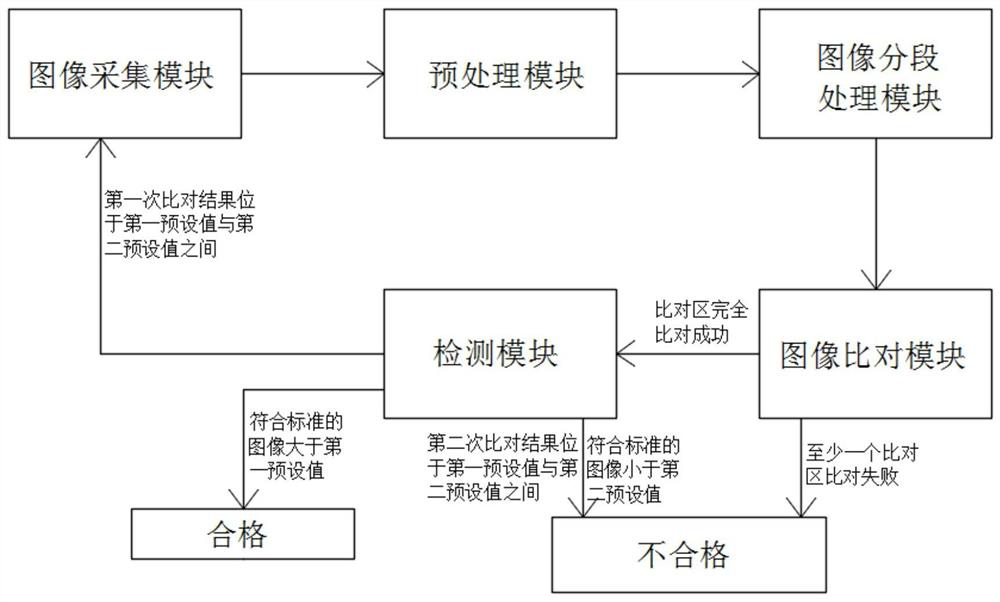

[0027] like figure 1 As shown, the present invention provides a processing and testing equipment for automobile hubs, the processing and testing equipment includes an image acquisition module, a preprocessing module, an image segmentation processing module, an image comparison module and a detection module; wherein,

[0028] The image collection module is used to collect multiple images of the same automobile wheel during processing;

[0029] The pre-processing module is used to perform edge-defining processing on multiple collected images and then stack them, and reconstruct a comparison image by taking a part whose number of stacks is not less than 50%;

[0030] The image segmentation processing module ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap