Novel cable joint explosion-proof box

A cable joint, explosion-proof box technology, applied in cable joints, electrical components, fire rescue and other directions, can solve the problems of FRP explosion and splash, waterproof glue burning, etc., to achieve convenient operation, reduce the loss and harm of accidents, good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

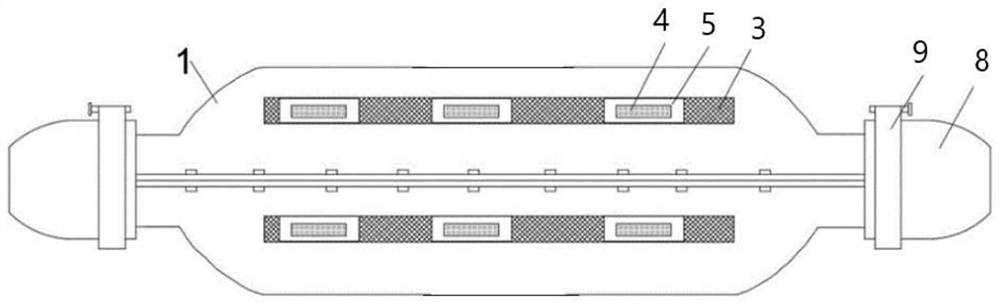

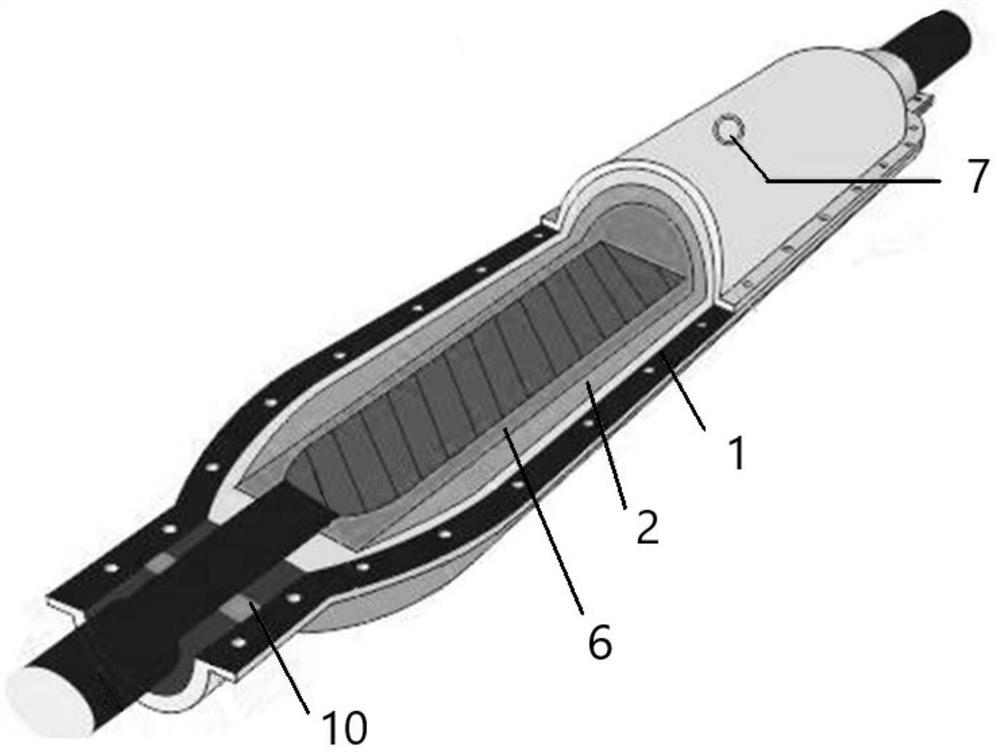

[0019] Such as figure 1 As shown, this embodiment provides a new type of cable joint explosion-proof box, including: shell 1, ceramic polyolefin inner layer 2, high-strength fiber layer 3, pressure relief hole 4, pressure relief cover plate 5, fire extinguishing egg 6, Shell glue filling port 7 and shell fastening device 8;

[0020] Wherein, the shell 1 is a combination structure of upper and lower double petals, the two sides of the shell 1 are in a contracted state, the upper and lower shells 1 wrap and clamp the cable, and a shell fastening device (8) is provided at the clamping place on both sides, and a shell fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com