Subway tunnel freezing pipe cutting machine and cutting method

A technology of frozen pipes and pipe cutters, which is applied in the direction of pipe shearing devices, shearing devices, and shearing equipment, etc., which can solve the problems of inconvenient use of equipment, easy damage to frozen walls, and high risk factors, and achieve labor and material costs. The effect of reducing, wide application range and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

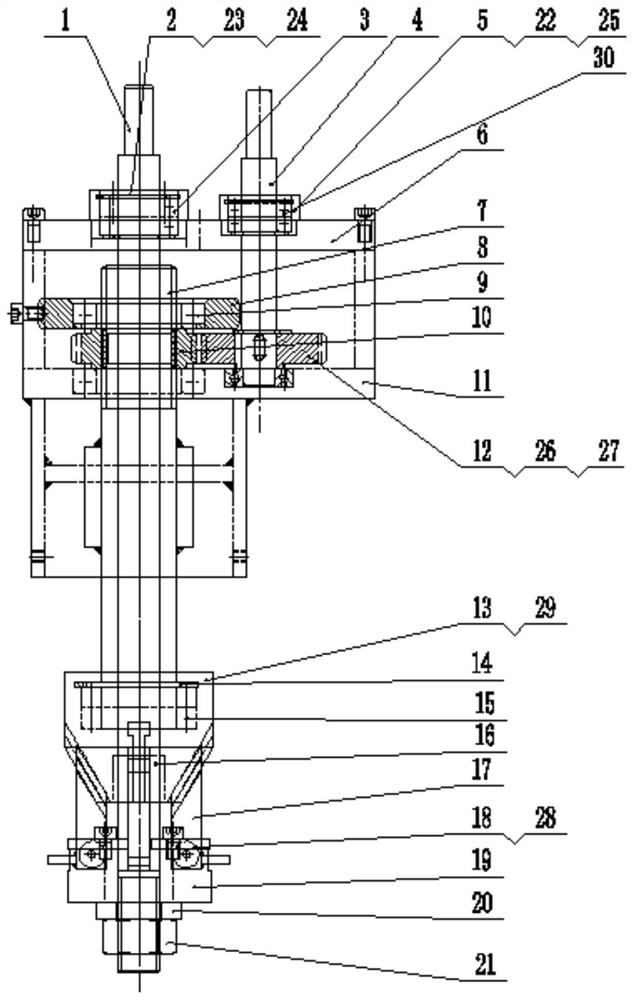

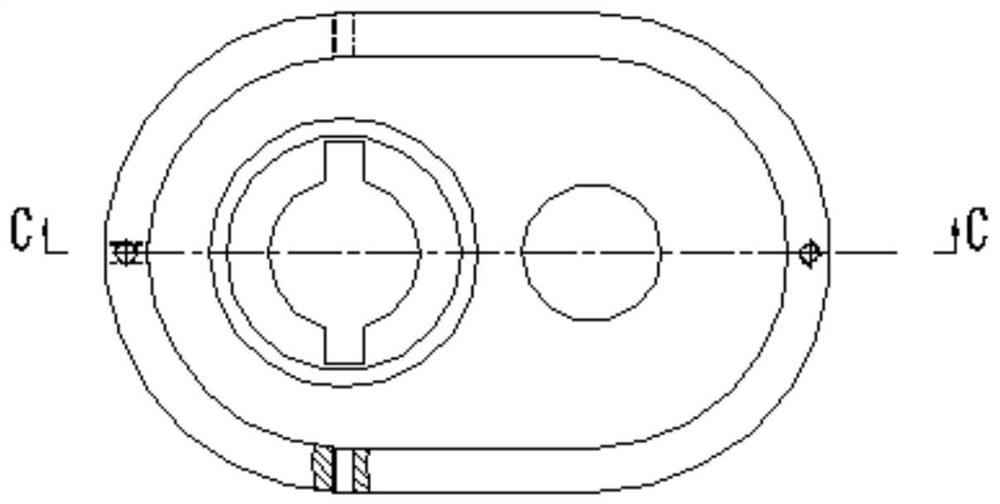

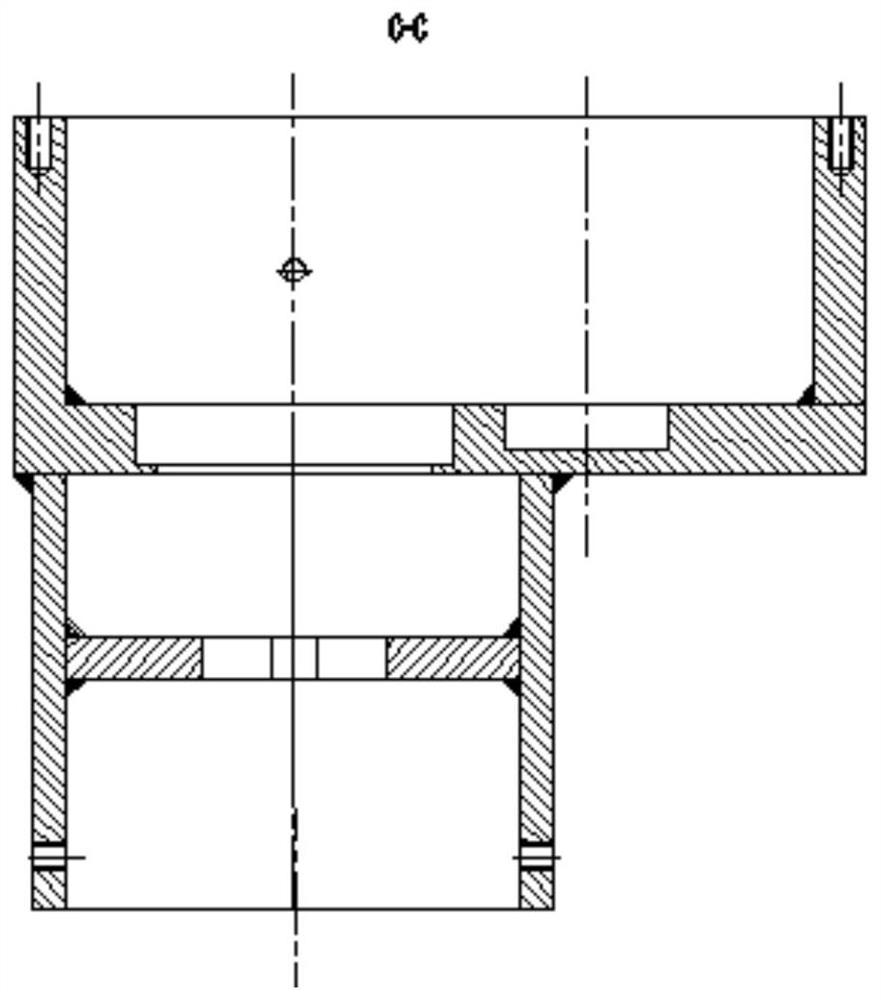

[0047] combine Figure 1 to Figure 3 As shown, a subway tunnel frozen pipe cutting machine includes a casing 11 with an open upper end, and the upper end of the casing 11 is fixed with a casing pressure plate 6 by screws. The upper end of the cutting shaft 1 is installed on the housing 11 through the bearing I3, and a large gland 2 is installed outside the bearing I3. The cutting shaft 1 and the bearing I3 are positioned through the circlip I24 for the shaft and the circlip I23 for the hole. The upper end of the feed shaft 4 is installed on the housing 11 through the bearing Ⅱ30, and the lower end of the feed shaft 4 is installed on the housing 11 through the bearing Ⅲ26; a small gland 5 is installed outside the bearing Ⅱ30, and the feed shaft 4 and the bearing Ⅱ30 pass through the shaft. Circlip II 22 and the hole are positioned with circlip II 25.

[0048] A knife feeding tube 7 is slidingly fitted on the cutting shaft 1; a bearing cover 8 is installed in the housing 11, an...

Embodiment 2

[0054] On the basis of above-mentioned embodiment one, a kind of subway tunnel frozen pipe cutting method, the steps are as follows:

[0055] Step 1: In the subway tunnel construction, push the trolley 31 equipped with equipment to a place suitable for cutting in the freezing area, select the location to fix the trolley 31, connect the equipment, and install the cutting flexible shaft, feeding flexible shaft, and cutting motor 32. Connect the feed motor 33;

[0056] Step 2: Select a suitable power distribution cabinet to connect to electricity on site, test the motor of the power distribution cabinet, test the pipe cutting machine, cut the flexible shaft, and feed the flexible shaft along the force;

[0057] Step 3: Extend the cutting shaft 1 of the pipe cutter into the frozen pipe about 15 to 20 cm, put the pipe cutter and the frozen pipe on a straight line as far as possible, and clamp the frozen pipe with the chuck at the front of the pipe cutter. outside of the pipe exten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap