Frame stability adjusting device

A technology of adjusting device and stability, applied in the direction of hoisting device, lifting frame, overhead line/cable equipment, etc., can solve the problems of heavy weight of cross arm and trouble in maintenance process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

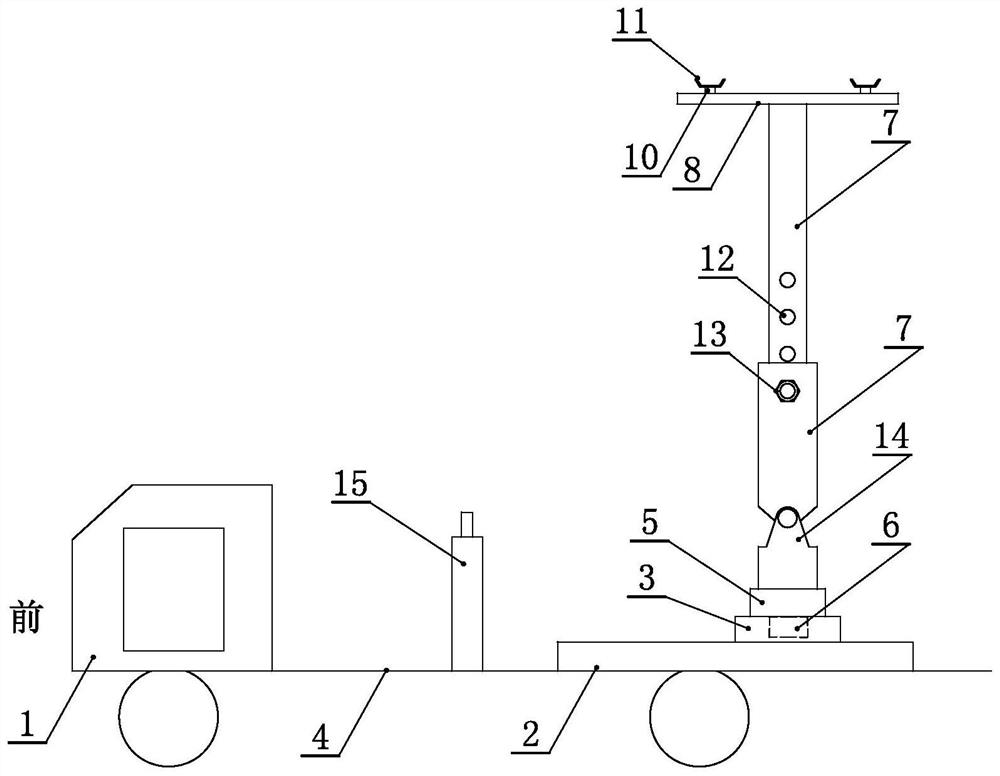

[0028] Embodiment one, such as figure 1 As shown, the invention includes a moving car body 1, a position adjustment component and a height adjustment component. Move the vehicle body 1 to carry the position adjustment component and the height adjustment component to the position where the transformer cross arm needs to be maintained or routinely overhauled. The position adjustment part is installed on the mobile car body 1, and the height adjustment part is installed on the position adjustment part, and can move on the position adjustment part. Specifically, the position adjustment component is installed in the vehicle bucket 4 of the moving vehicle body 1. From the front and rear direction of the mobile vehicle body 1, the position adjustment component is located at the rear of the vehicle, and from the left and right direction, it is located at the center of the vehicle bucket 4. During specific use, the height adjustment component can be moved to the position of the rear o...

Embodiment 2

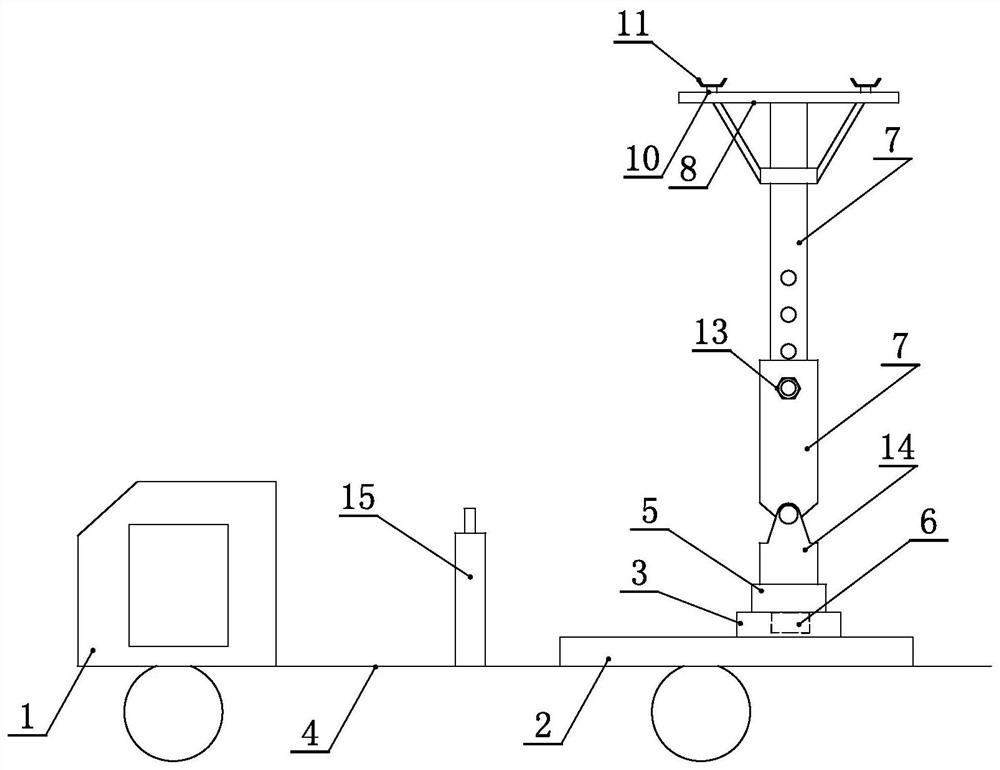

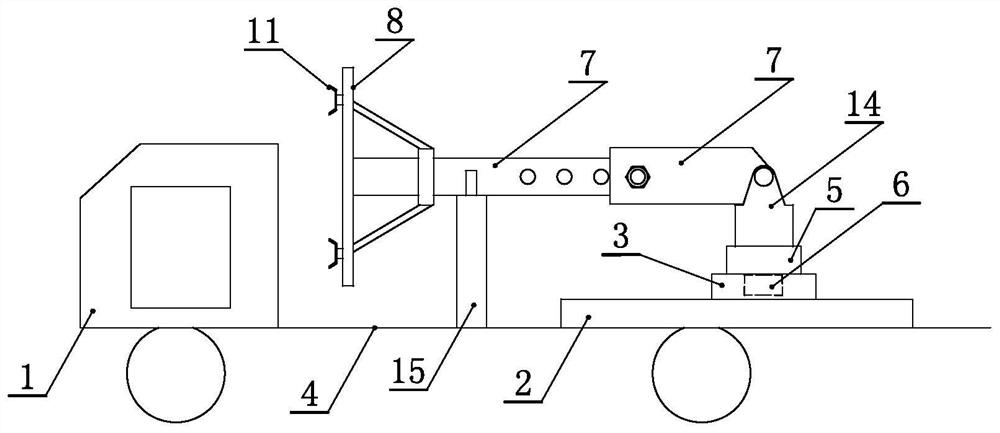

[0039] Embodiment two, such as figure 2 , image 3 As shown, the difference from Embodiment 1 is that the crossbar 8 is connected to the adjustment rod 7 through oblique supports and bearings. The connecting cross bar 8 and the oblique support can rotate axially around the adjusting rod. The crossbar 8 is connected with the adjusting rod through the oblique support and the bearing, and the crossbar 8 and the oblique support can rotate axially around the adjusting rod under manual intervention to realize the angle adjustment of the crossbar 8 and the abutment parts on the crossbar 8.

[0040] By moving the car body 1, the height adjustment component is transported to the position of the frame body that needs maintenance, the height adjustment component is adjusted along the position adjustment component, and then the quantity and positional relationship of the adjustment rod in the height adjustment component is reasonably adjusted according to the height requirement, to The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com