Rolling bearing device and rolling bearing

A technology of rolling bearings and bearings, applied in the field of rolling bearings, can solve the problems of bearing internal pressure increase, temperature peak, friction increase, etc., and achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

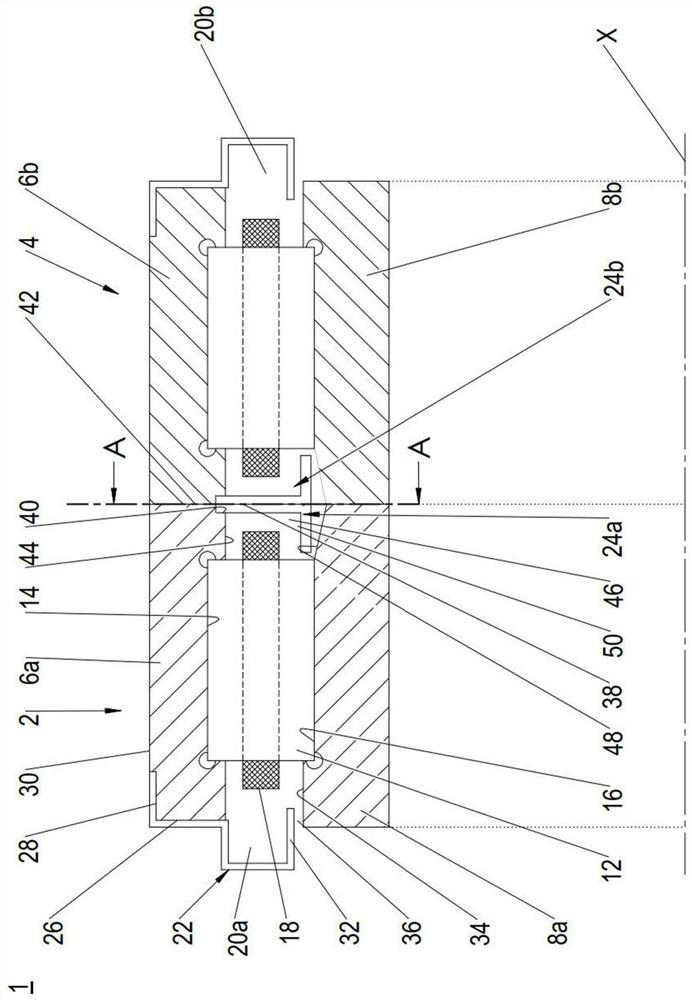

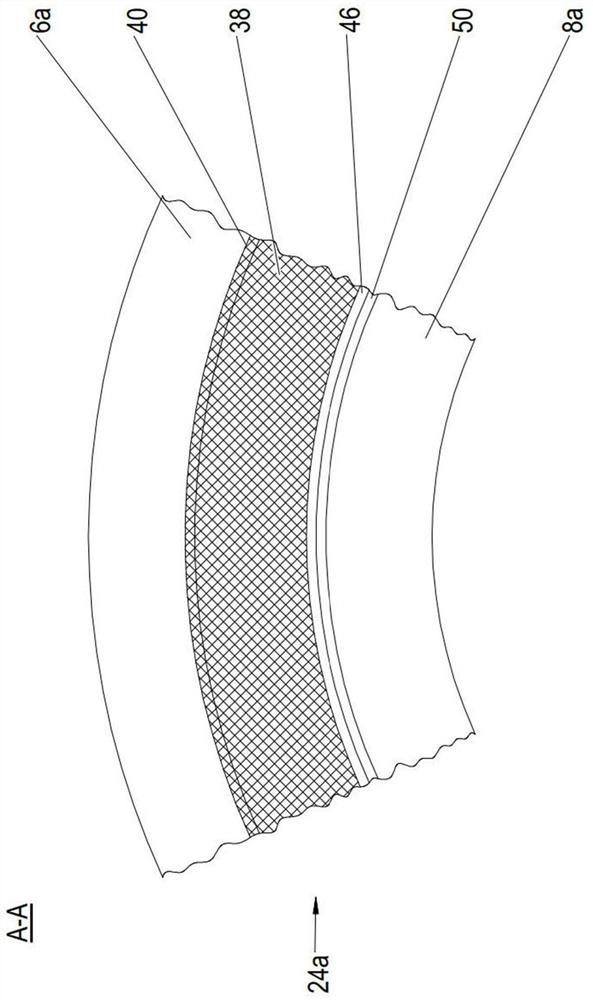

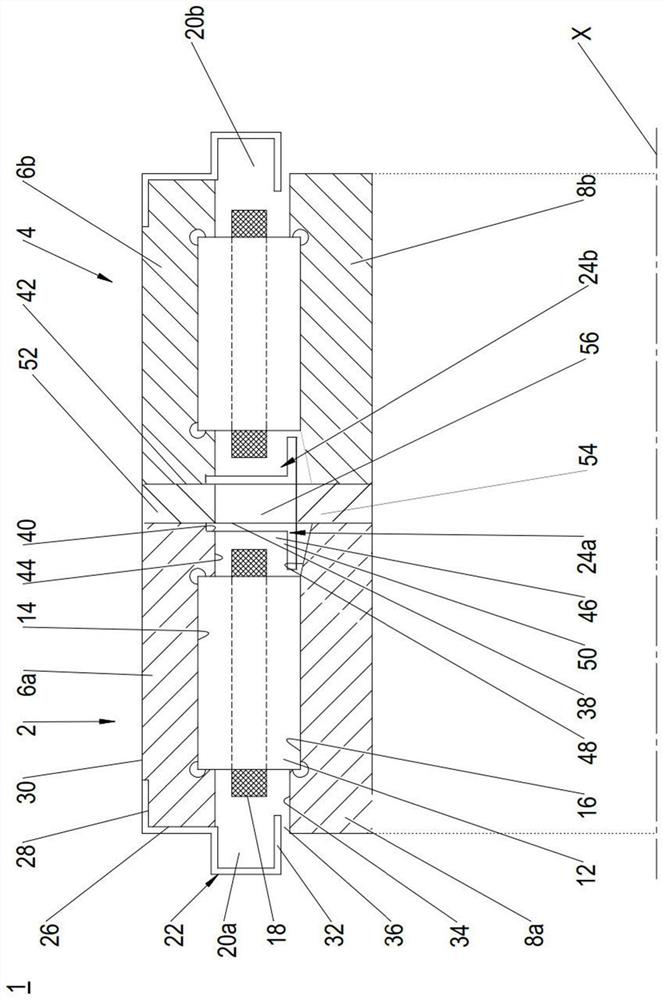

[0025] figure 1 A first preferred exemplary embodiment of the rolling bearing arrangement 1 according to the invention is shown, which is designed here as a double-row cylindrical roller bearing. The rolling bearing arrangement 1 in the exemplary embodiment shown here has two radial rolling bearings 2 , 4 each having rolling rows. The rolling bearings 2 , 4 each have a radially outer outer ring 6 a , 6 b and a radially rear inner ring 8 a , 8 b , between which the rolling rows are arranged with their rolling bodies 12 . The rolling bearings 2 , 4 are oriented axially aligned with respect to the bearing center axis or the axis of rotation x and are connected to one another at the ends. All statements below, such as "radially inner" and "radially outer", refer to the axis of rotation x. The mutually abutting outer rings 6 a , 6 b and the mutually abutting inner rings 8 a , 8 b are preferably axially clamped together, for example by means of screws (not shown).

[0026] The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com