Flue gas purification system and purification method

A flue gas purification system and flue gas purification technology, applied in the field of flue gas purification, can solve the problems of affecting the exhaust effect, large filter screen resistance, low filtering efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

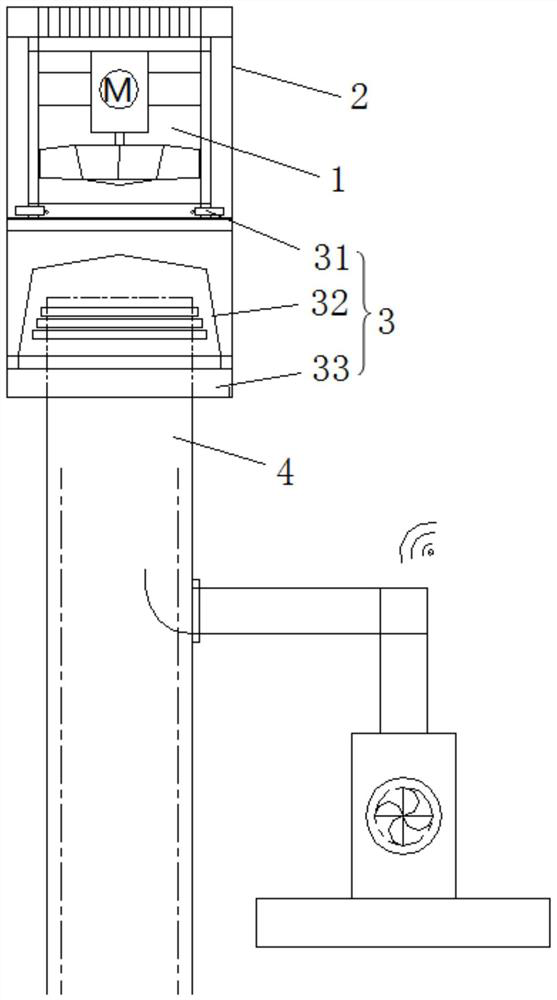

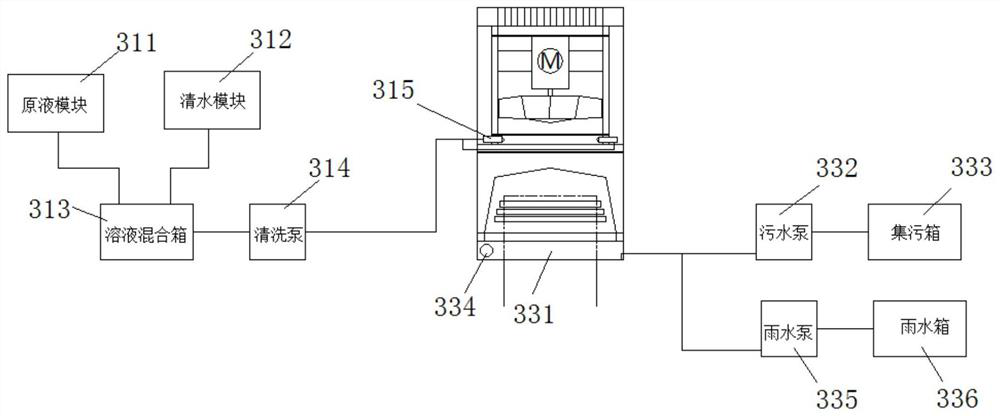

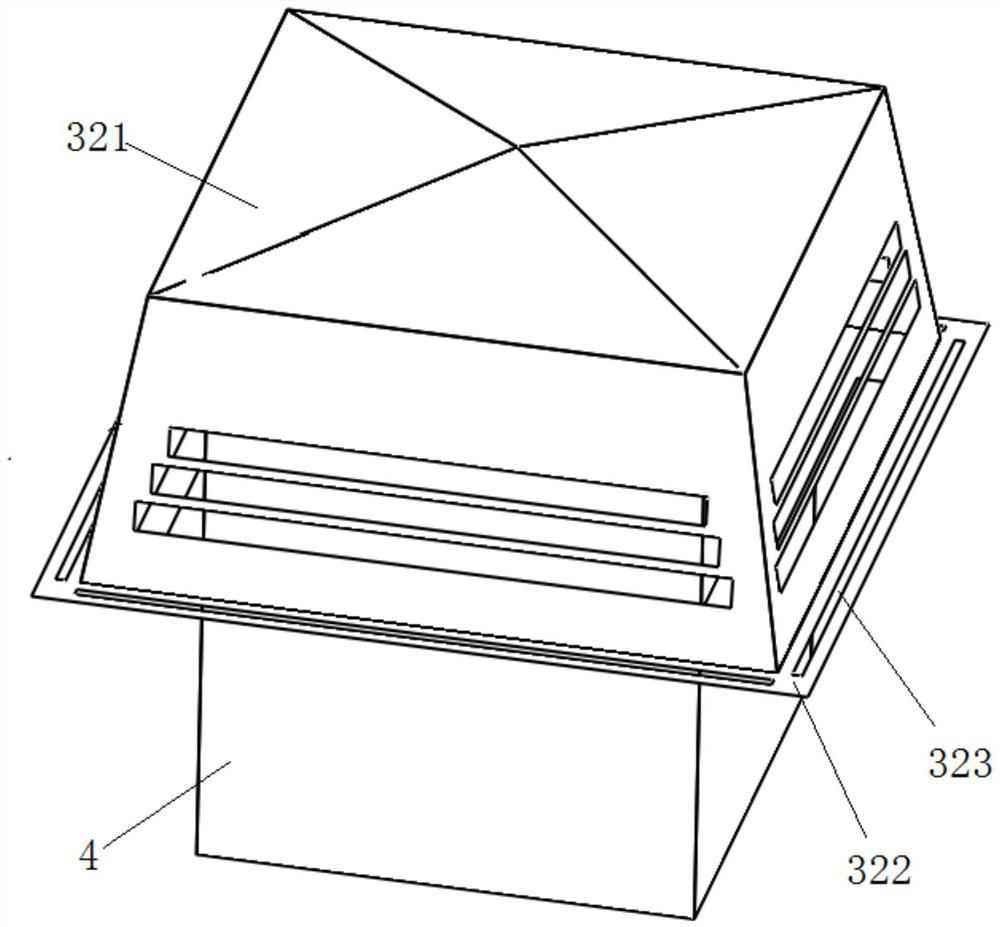

[0041] Embodiment 1 of the present invention provides a flue gas purification system for purifying the flue gas discharged from the smoke exhaust system, such as figure 1 As shown, it includes a fan 1, a protective cover assembly 2, a purification assembly 3, a flue extension pipe 4 and a control assembly 5. Above the assembly 3, the lower end of the flue extension pipe 4 is connected to the flue of the smoke exhaust system, and the upper end is connected to the purification assembly 3; the control assembly 5 is connected to both the fan 1 and the purification assembly 3; the control assembly 5 obtains The number of range hoods in working condition, according to which the concentration of the cleaning liquid in the purification assembly 3 is controlled to purify the flue gas discharged from the flue extension pipe 4;

[0042] Specifically, the upper surface of the protective cover assembly 2 is made of a protective net;

[0043] In this way, with the above structure, the flue...

Embodiment 2

[0078] Embodiment 2 of the present invention provides a flue gas purification method, which uses the flue gas purification system described in Embodiment 1, such as Figure 7 As shown, it specifically includes the following steps:

[0079] S1, the control component acquires the number of range hoods in working state;

[0080] S2, the control component adjusts the concentration of the cleaning liquid in the purification component according to the quantity in S1, and the purification component realizes the purification of the flue gas through the cleaning liquid of this concentration.

[0081] In this embodiment, the cleaning liquid is used to purify the flue gas. Compared with the traditional method of purifying through a filter, the flue gas will not be hindered, so the smoke exhaust effect will not be affected; moreover, the concentration of the cleaning liquid in this embodiment also follows the The number of range hoods in working condition is adjusted, which is targeted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com