Anti-wear stranding device for electric wire production line

A wear-resistant, production-line technology that can be used in circuits, electrical components, cable/conductor manufacturing, etc., to solve problems such as scratched wires, wire abrasion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

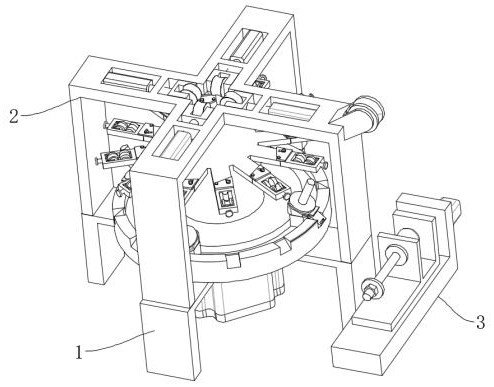

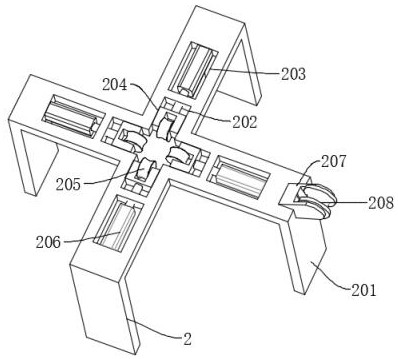

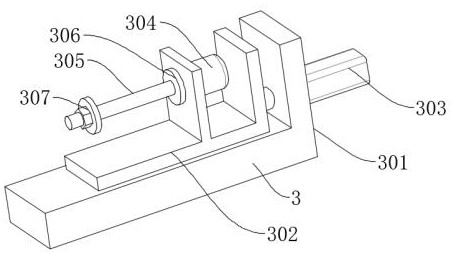

[0034] like Figure 1-7 As shown, a wear-resistant twisting device used in a wire production line includes a winding mechanism 3, a twisting mechanism 1 and a guiding mechanism 2, and the twisting mechanism 1 includes a support frame 101, a driving motor 102, and a turntable 103 , annular chute 104, fixed assembly 105, column 106, support plate 107, the bottom center of support frame 101 is connected with drive motor 102 by bolt, the output end of drive motor 102 passes support frame 101, and stretches into turntable 103 insides, And it is connected with the turntable 103 by a key, the top of the turntable 103 is provided with an annular chute 104 and several draw-in grooves, the draw-in groove is positioned at the outer side of the annular chute 104, and the inner side of the annular chute 104 is slidably connected with a fixed assembly 105, and the turntable 103 The center of the top is welded with a column 106, and the outer top of the column 106 is connected with several s...

Embodiment 2

[0037] like Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that the driving structure includes slider three 504 and cylinder two 51, slider three 504 is slidably connected to the inner side of chute two 502, and slider three 504 is close to the fixed guide wheel 503 One end of one end is provided with the installation slot that is used to install the moving guide wheel 506, and the end of the slider three 504 away from the fixed guide wheel 503 is connected to the output end of the cylinder two 51 by bolts, and the fixed end of the cylinder two 51 is connected to the outside of the fixed frame 501 by bolts , such arrangement can drive slide block three 504 to move by cylinder two 51, and slide block three 504 drives moving lead wheel 506 to move, and electric wire is extruded between moving lead wheel 506 and fixed lead wheel 503, prevents electric wire from swinging.

[0038]In the above structure, when in use, first place an appropriate number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com