Reluctance rotor, motor and compressor

A rotor and reluctance technology, applied in the field of compressors, can solve the problems of high cost, unacceptable market, and low motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

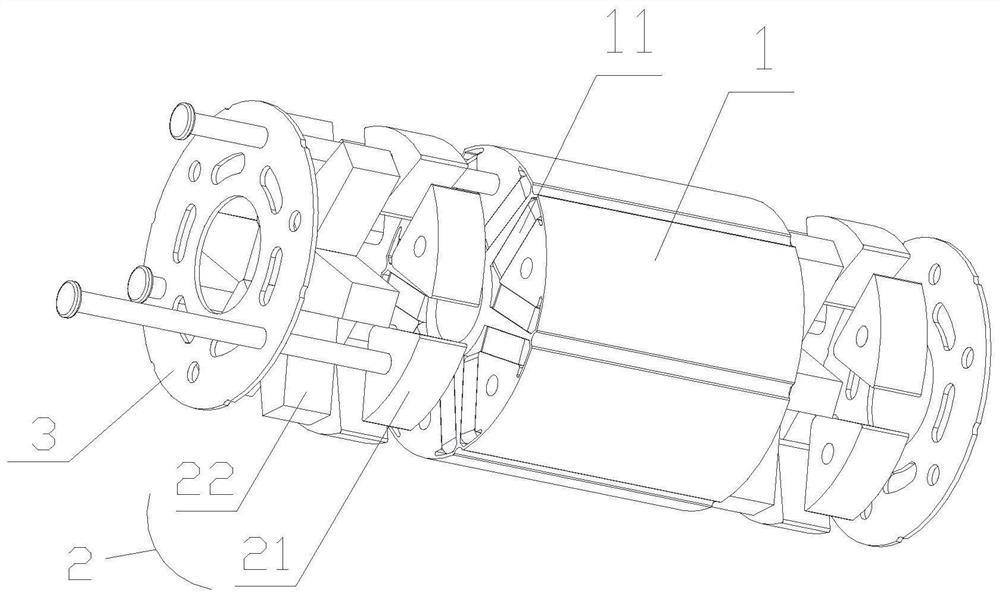

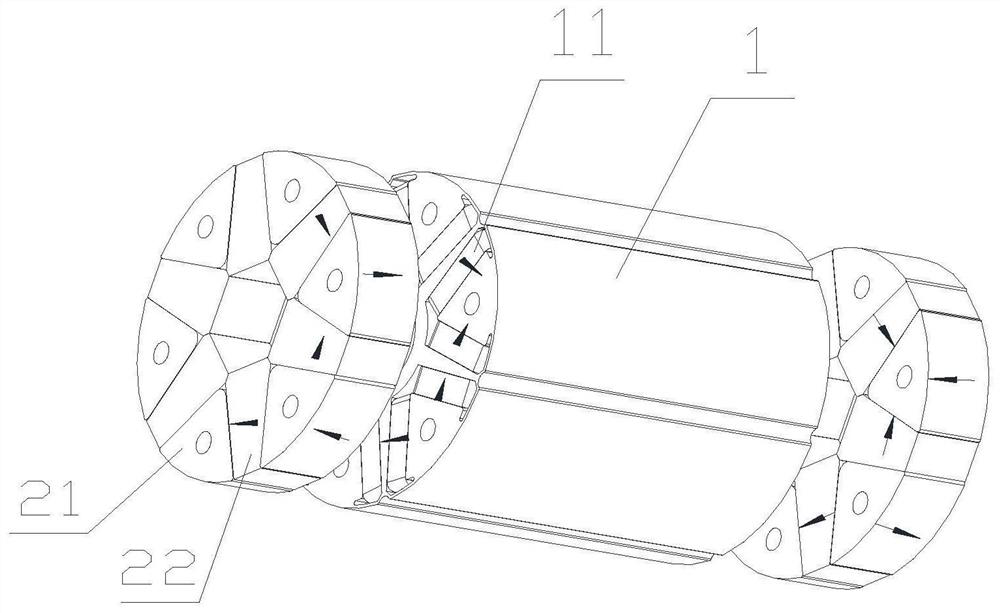

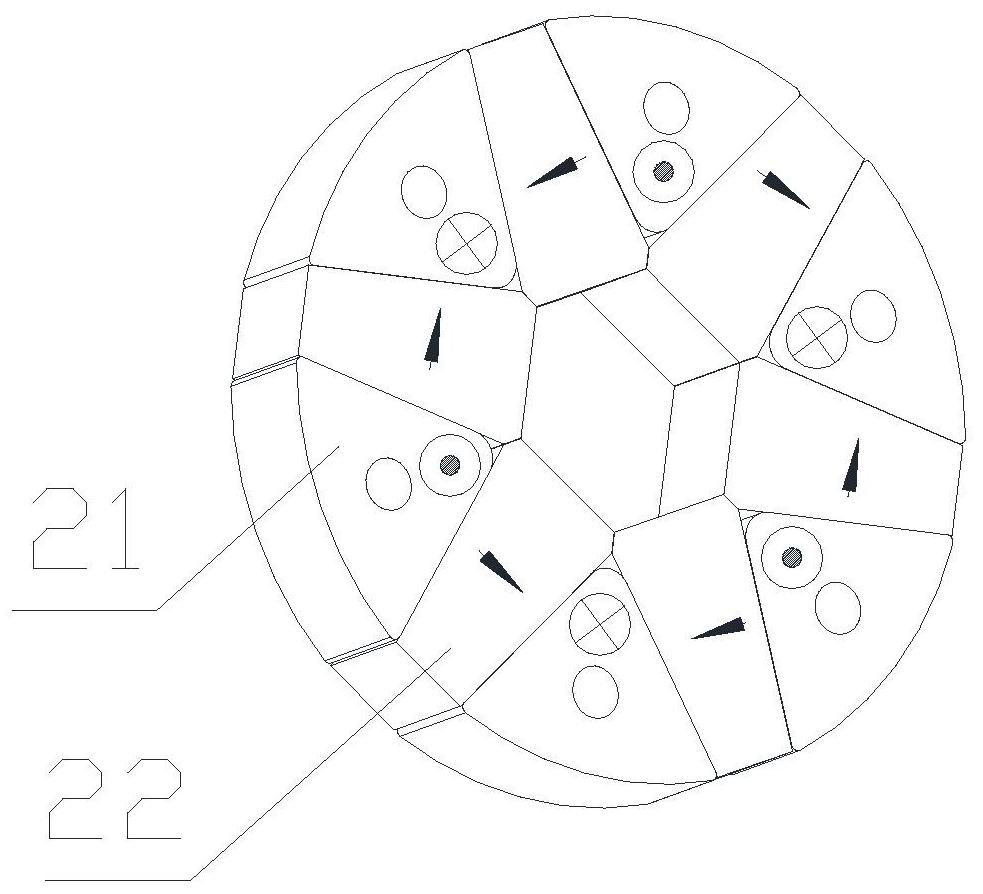

[0025] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present application, a reluctance rotor includes:

[0026] The rotor core 1 includes a magnetic steel slot;

[0027] The first magnetic steel part 11 is arranged in the magnetic steel groove;

[0028] The second magnetic steel part 2 is arranged on the end surface of the rotor core 1 .

[0029] Since the reluctance motors are all axially symmetrical structures, the first magnetic steel part 11 is arranged in the magnetic steel slot provided in the rotor core 1, and the leakage reactance at the end is relatively large, and the utilization rate of the magnetic steel is low; The second magnetic steel part 2 is arranged on the end surface of 1, which can form a three-dimensional magnetic gathering structure, reduce leakage reactance at the end, increase the utilization rate of the magnetic steel, and improve the electromagnetic torque ratio.

[0030] In some embodiments, the second magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com