Mechanism for disassembling disc parts of aero-engine

A technology for aero-engine and disk parts, which is applied in the field of disk parts decomposition, can solve the complexity of the assembly and decomposition process, and achieve the effect of simple operation process, meeting the needs of production and use, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

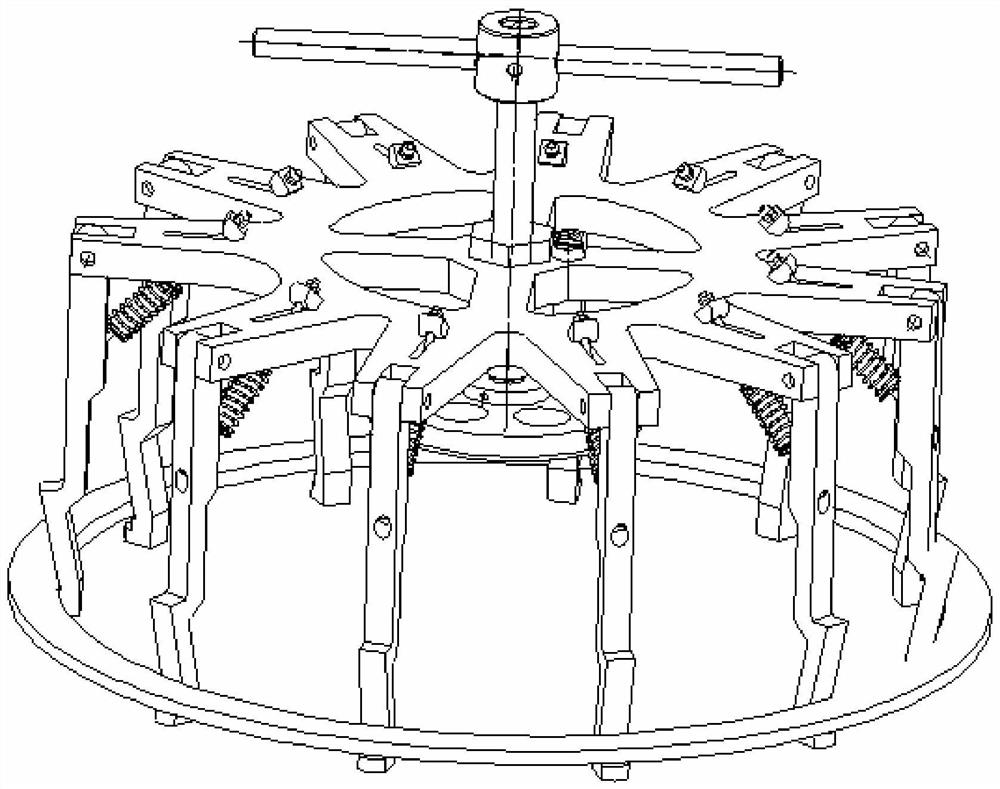

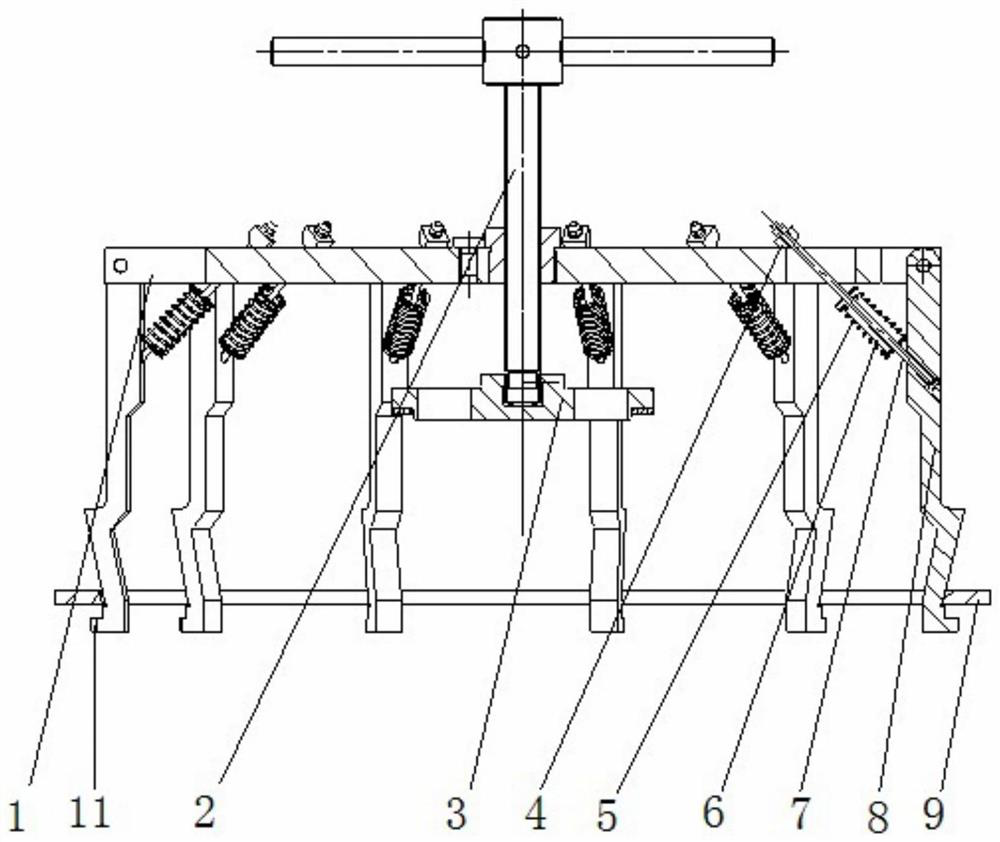

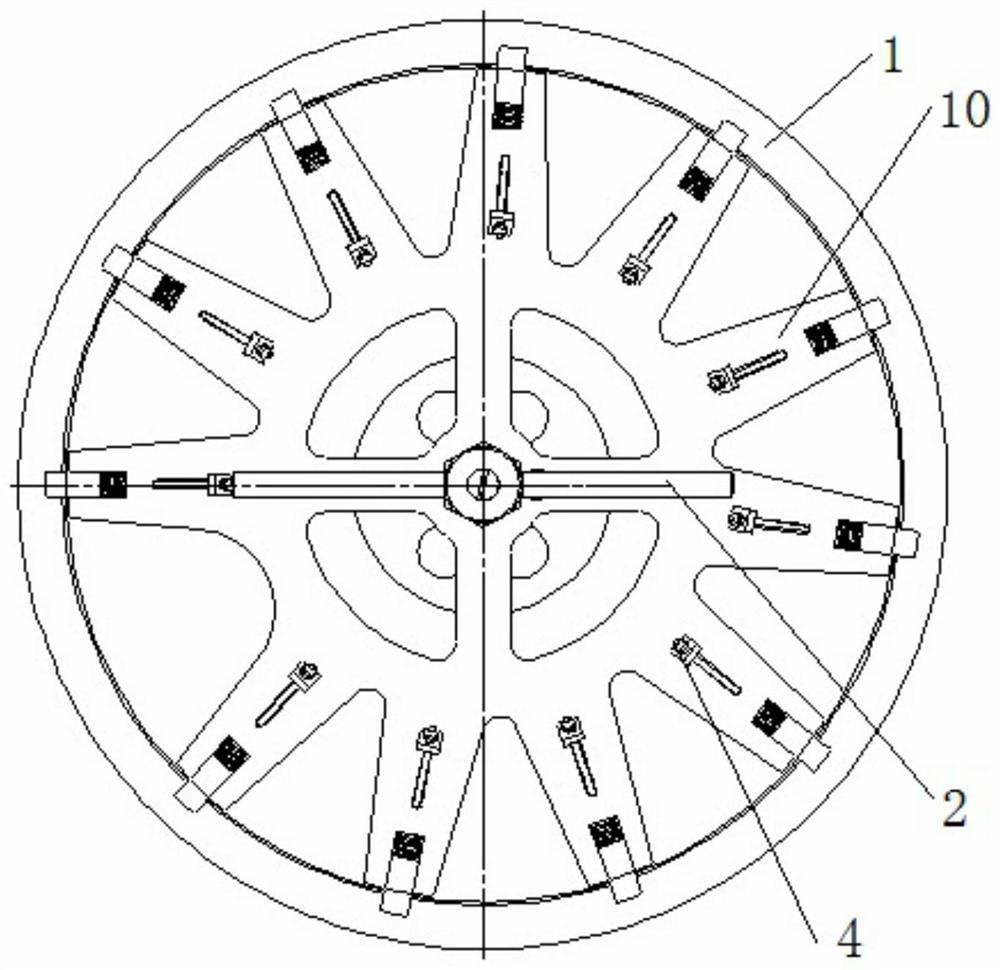

[0028] Such as Figure 1-3 A mechanism for disassembling disc parts of an aero-engine is shown, which is characterized in that it includes a tray 1, a tightening bolt 2, a tightening disc 3, an R-shaped nut 4, a spring 5, a spring mandrel 6, a pull rod 7, a clamp Claw 8 and limit ring 9;

[0029] The tray 1 is disc-shaped, with eleven mounting teeth 10 distributed around the circumference; and the mounting teeth are provided with bar-shaped grooves;

[0030] One end of the claw 8 is connected to the mounting tooth 10 of the tray;

[0031] The other end of the claw 8 is provided with a step-shaped clamping platform 11 that cooperates with the limit ring 9;

[0032] One end of the pull rod 7 is connected to the wall of the claw 8, and the other end is connected to the bar groove of the installation tooth 10, and the pull rod 7 is provided with a spring mandrel 6, the spring 5 is sleeved on the spring mandrel 6, and the pull rod 7 Clamped on the bar groove through the R-type n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com