Raw material mixing device for concrete production

A mixing device and concrete technology, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of single rotating shaft, uneven mixing, etc., and achieve the effect of improving the mixing effect and improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

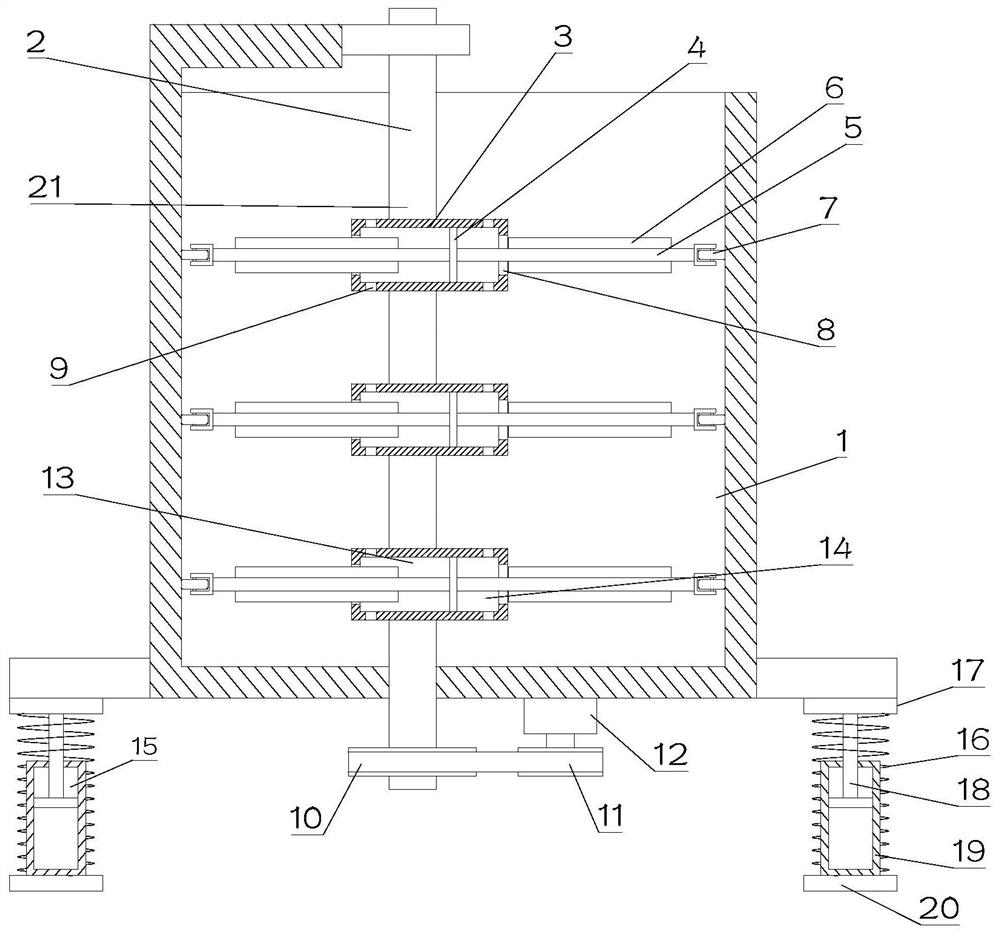

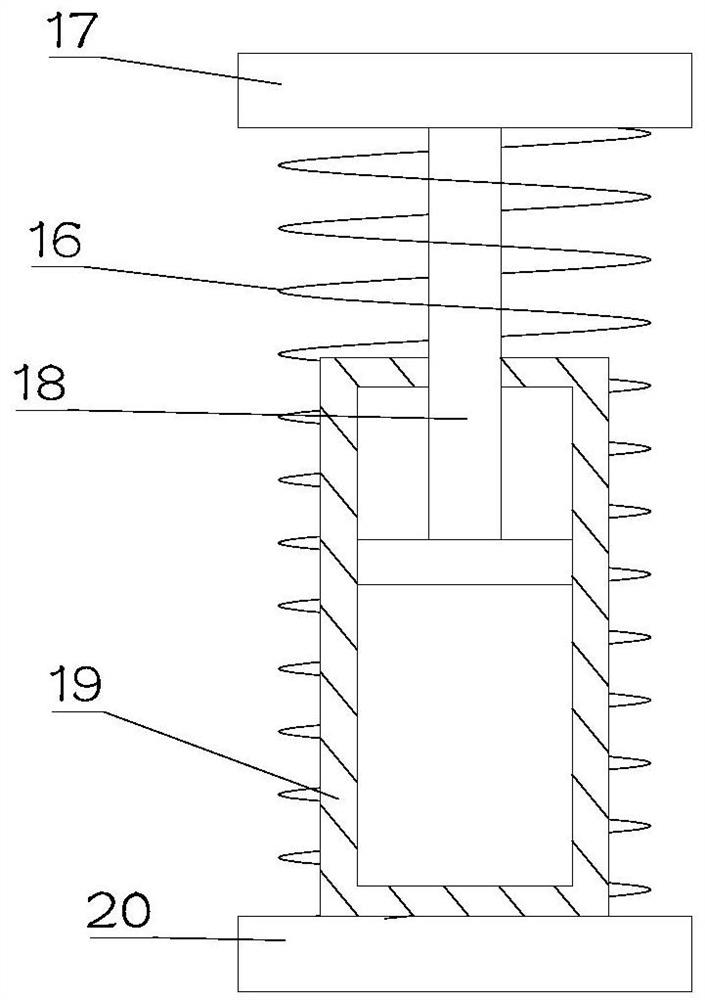

[0025] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a raw material mixing device for concrete production provided by the embodiment of the present invention, including: a device main body 1, which is provided with a mixing chamber for raw material mixing;

[0026] Stirring component 2 is eccentrically arranged inside the device main body 1;

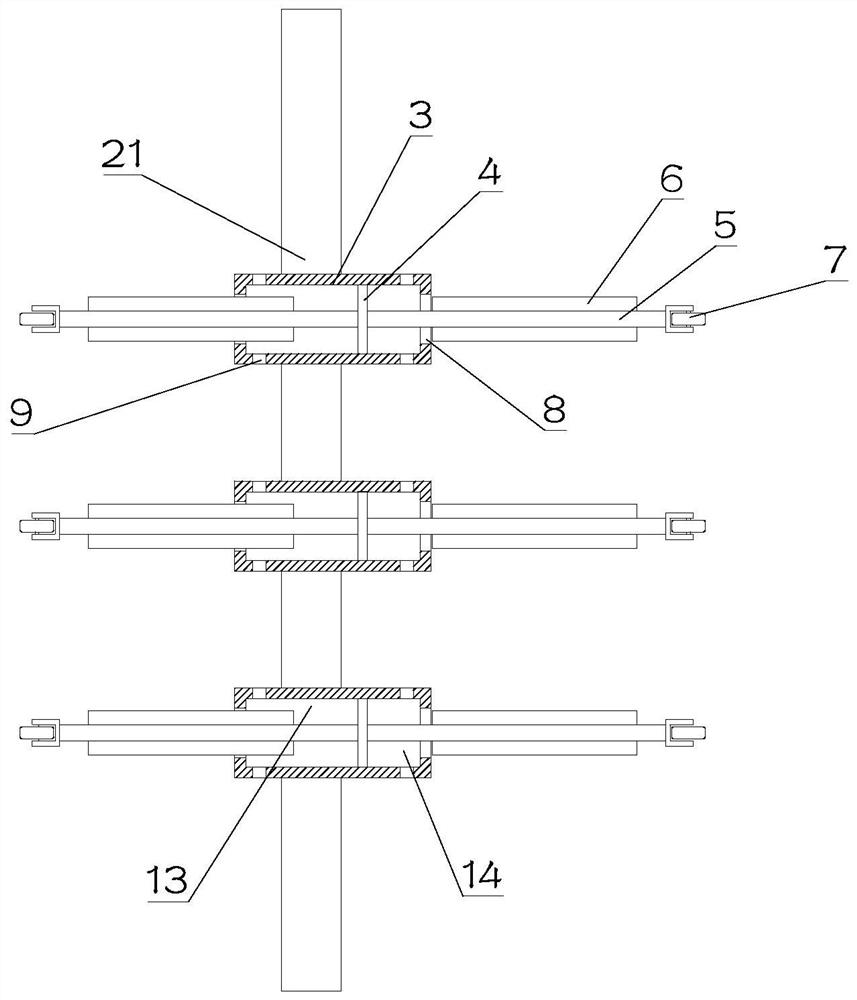

[0027] Wherein, the stirring assembly 2 includes a stirring shaft 21 which is eccentrically rotated inside the device main body 1, and a plurality of cylinders 3 are arranged in an array on the stirring shaft 21, and a plurality of cylinders 3 are provided with reciprocating sliding pistons. 4. The connecting rod 5 is set through the cylinder body 3 and the piston 4, and the piston 4 is fixedly arranged at the middle position of the connecting rod 5, the piston 4 is fixedly installed on the connecting rod 5, and the two ends of the connecting rod 5 are respectively slid and pasted on the On th...

Embodiment 2

[0031] see Figure 1~3 , in Embodiment 2 of the present invention, both ends of the connecting rod 5 are provided with stirring blades 6 , and the stirring blades 6 are arranged on the upper and lower sides of the connecting rod 5 . Thus, the raw materials can be well stirred and mixed.

[0032] The piston 4 divides the interior of the cylinder 3 into a first cavity 13 and a second cavity 14, and the end of the first cavity 13 and the second cavity 14 away from the piston 4 is provided with a through hole 8, and the through hole 8 is set. 8 to facilitate the passage of the connecting rod 5; the ends of the first cavity 13 and the second cavity 14 are respectively provided with communication holes 9, which facilitate the entry of raw materials or the removal of raw materials.

[0033] Specifically, when the connecting rod 5 rotates with the stirring shaft 21, due to the eccentric arrangement of the stirring assembly 2, the piston 4 slides back and forth inside the barrel 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com