Injection mold with multi-aperture adjustment

An injection mold and multi-aperture technology, which is applied in the field of injection molds with multi-aperture adjustment, can solve the problems that the inlet aperture cannot be adjusted, the injection hole aperture cannot be adjusted, and the injection molding is inferior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

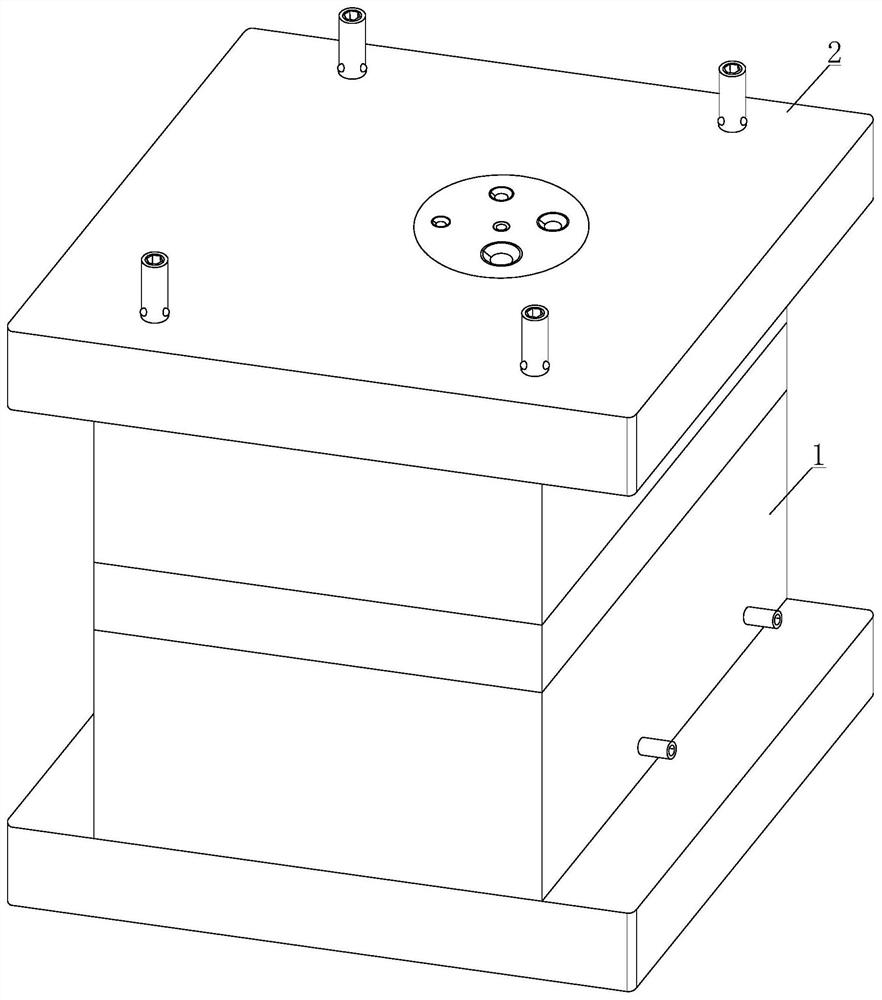

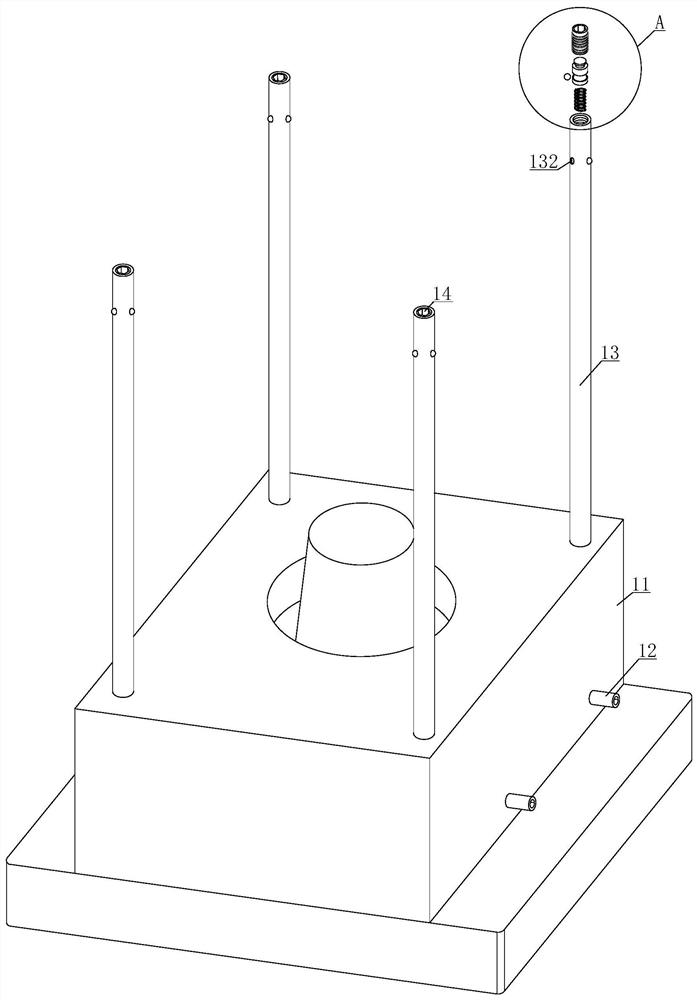

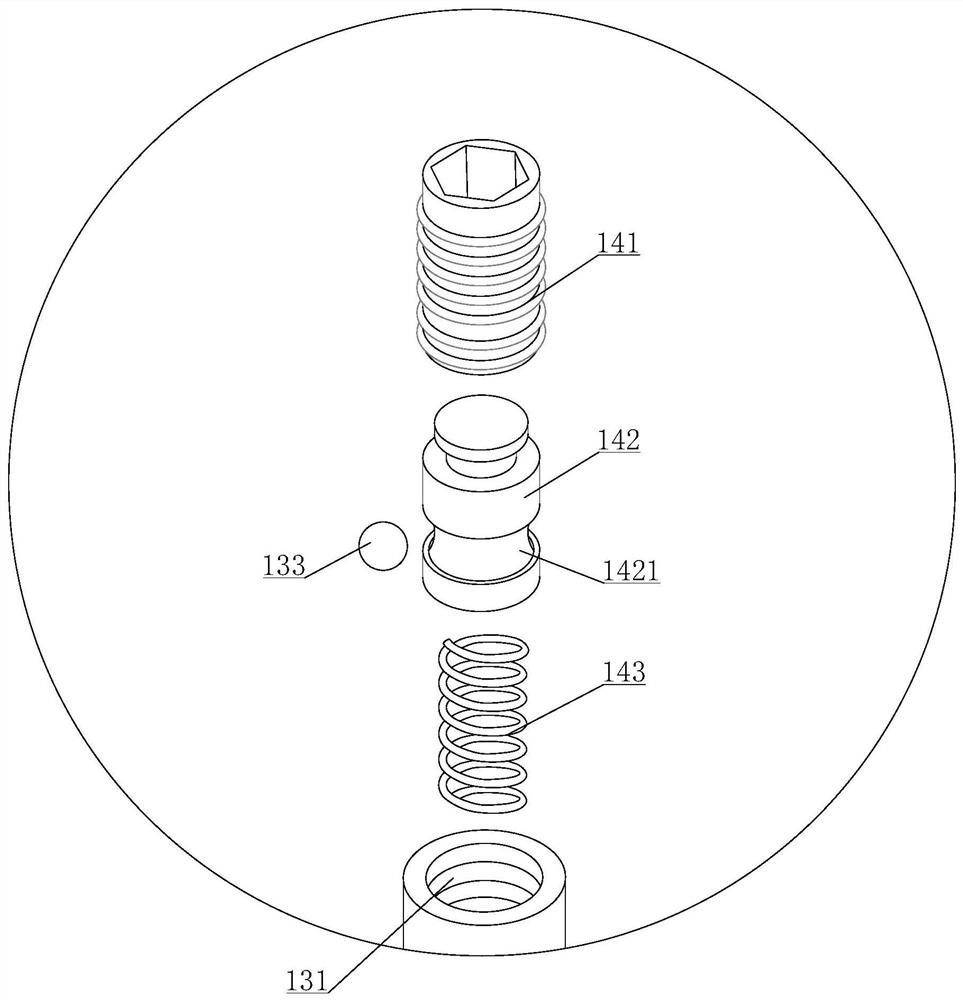

[0033] see Figure 1-3, an injection mold with multi-diameter adjustment, including a first mold 1 and a second mold 2, the lower end of the first mold 1 is equipped with a second mold 2, the first mold 1 includes a bottom mold 11, a cooling hole 12, a positioning rod 13. The positioning rod 13 includes a threaded hole 131, a bead hole 132 and a positioning bead 133. The upper end of the positioning rod 13 is provided with a threaded hole 131. The outer surface of the positioning rod 13 is provided with a bead hole 132. The inner cavity of the bead hole 132 is equipped with a positioning bead. 133, the fixing device 14, the fixing device 14 includes a threaded column 141, a limiting column 142 and a first spring 143, the bottom surface of the threaded column 141 is equipped with a limiting column 142, the lower end of the limiting column 142 is equipped with a first spring 143, and the limit The side of the positioning column 142 is provided with an arc groove 1421, and the fi...

Embodiment 2

[0035] see Figure 4 , the second mold 2 includes a movable mold 21, a buffer plate 22, an adjustment assembly 23 and a positioning hole 24, a buffer plate 22 is installed on the lower end of the movable mold 21, an adjustment assembly 23 is installed on the upper end of the movable mold 21, and the four corners of the upper end of the movable mold 21 A positioning hole 24 is opened.

Embodiment 3

[0037] see Figure 5-6 , the movable mold 21 includes a fixed assembly 211, the fixed assembly 211 includes a rotating plate 2111, a triangular block 2112 and a second spring 2113, one end of the cavity of the fixed assembly 211 is movably installed with a rotating plate 2111, and one end of the rotating plate 2111 is installed with a triangular block 2112 , the other end of the rotating plate 2111 is installed with a second spring 2113, a first limit assembly 212, the first limit assembly 212 includes a third spring 2121 and a first limit groove 2122, and the inner cavity of the first limit assembly 212 is installed There is a third spring 2121, and a first limiting groove 2122 is provided on the inner cavity wall of the first limiting component 212. When the turntable 231 rotates to adjust the injection holes 2311 with different R-angle diameters, the ratchet 2312 installed on the side of the turntable 231 will move together. Rotate, the injection hole 2311 rotates countercl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com