Low-noise and energy-saving double-shell slurry pump

A slurry pump and low-noise technology, applied to components, pumps, and pump controls of elastic fluid pumping devices, can solve problems such as reduced service life, easy solidification, and easy residual mixed liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

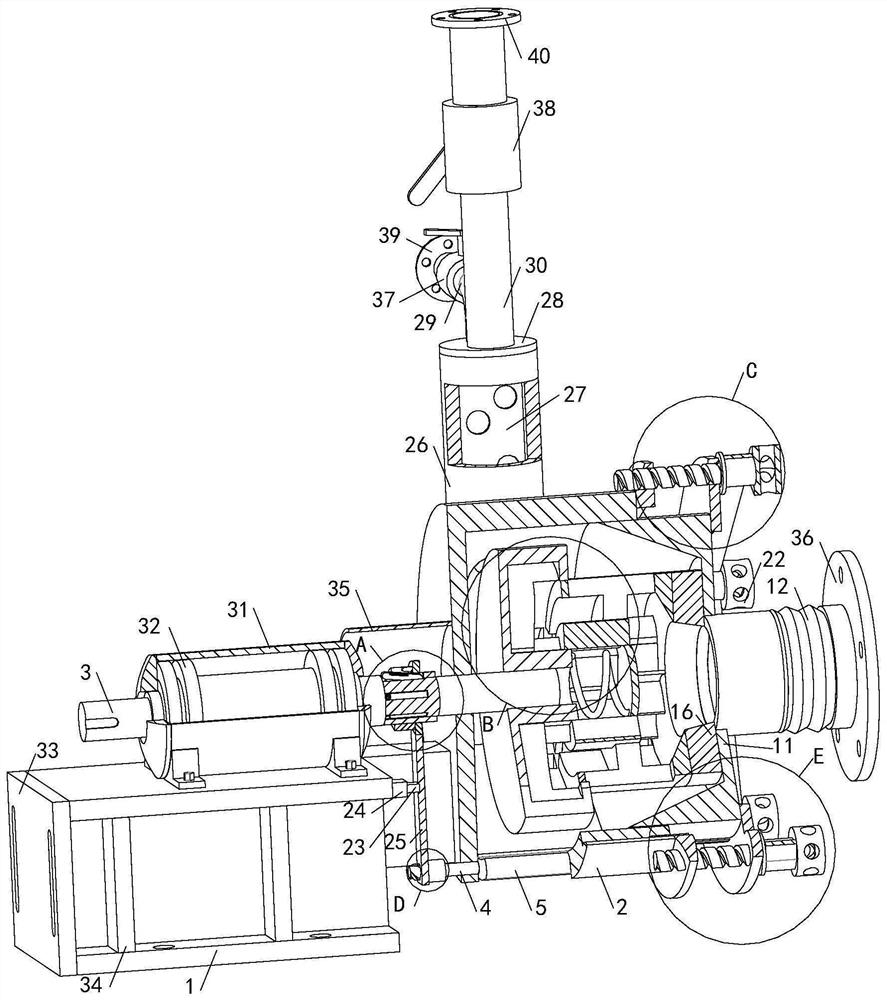

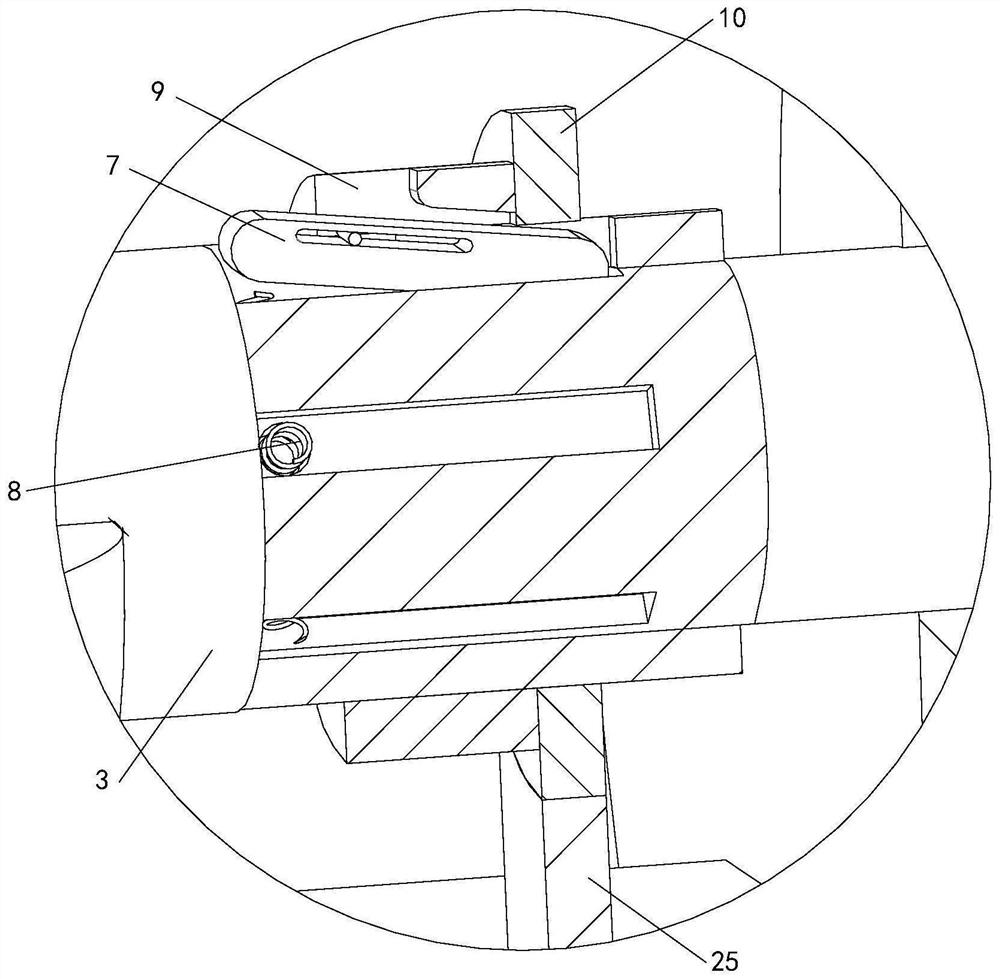

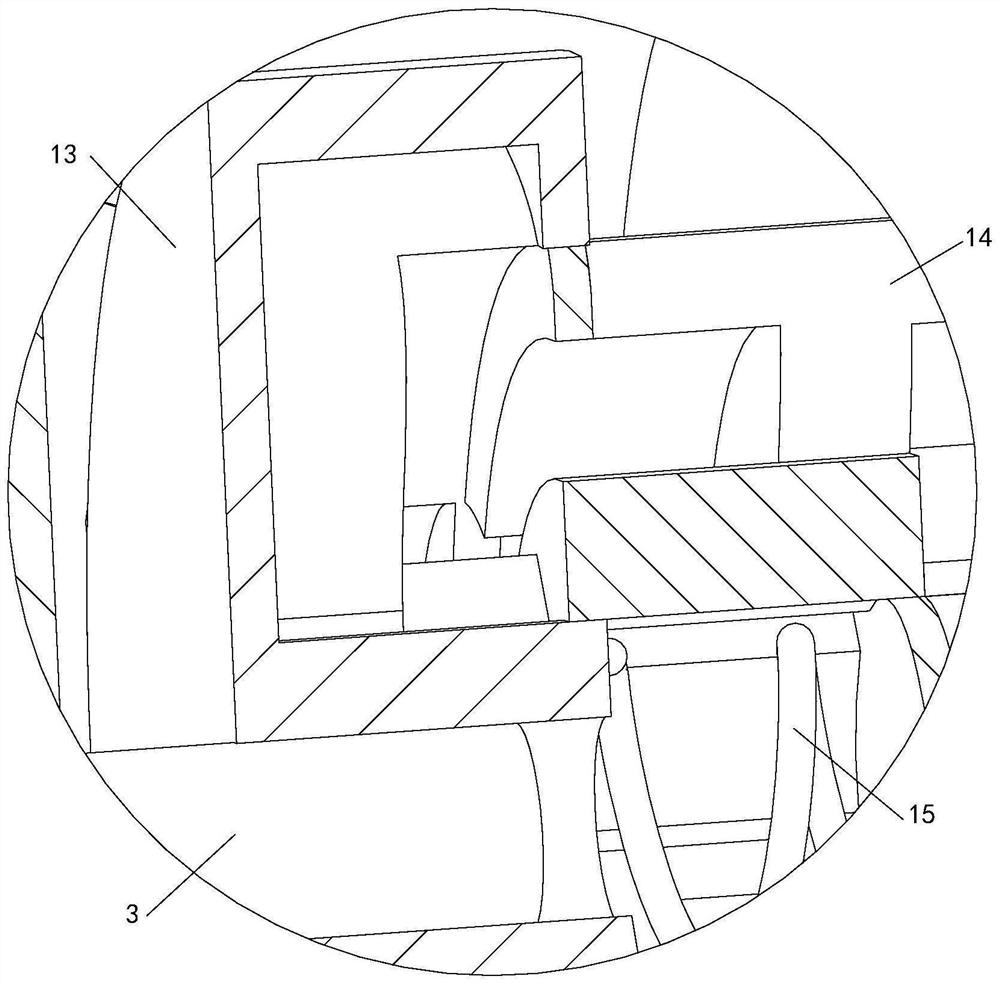

[0033] see Figure 1-7 , a low-noise and energy-saving double-shell slurry pump, including a bracket 1 and a pump body 2, the pump body 2 is fixedly connected with the bracket 1, the bracket 1 is connected with a stepped shaft 3 through a bearing frame mechanism, and the bearing frame The mechanism includes a support cylinder 31, which is fixedly connected with the bracket 1. The support cylinder 31 is connected with the stepped shaft 3 through a plurality of ball bearings 32, which is convenient to improve the rotation stability of the stepped shaft 3, and has better lubrication and longer service life. Long, the stepped shaft 3 is rotatably connected with the pump body 2, and the pump body 2 is connected with a liquid separation mechanism. The liquid separation mechanism includes a thick tube 26, which communicates with the pump body 2, and the thick tube 26 is fixedly connected with a separation filter plate 27. The separation filter plate 27 is connected to the pump body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com