Cooling device of compressor

A cooling device and compressor technology, applied in the field of compressors, can solve the problems of heat concentration and inability to dissipate, the strength of the oil film is reduced, and the space is limited, so as to achieve the effects of improving the circulating cooling efficiency, improving the service life, and having a simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

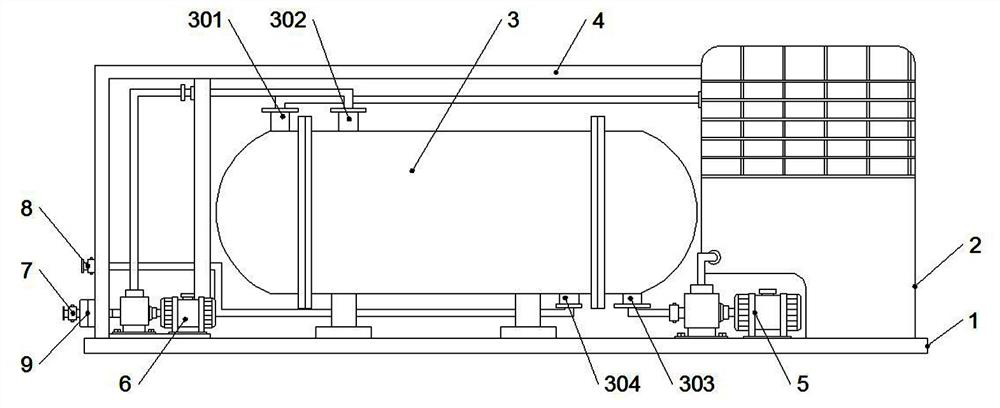

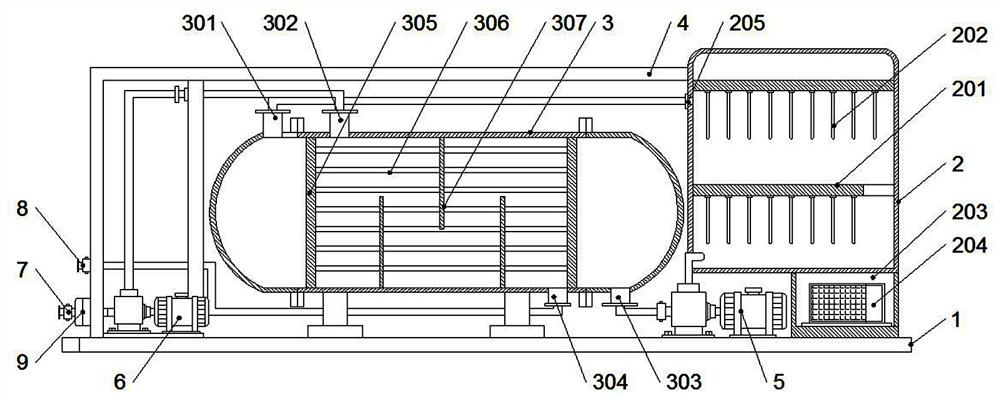

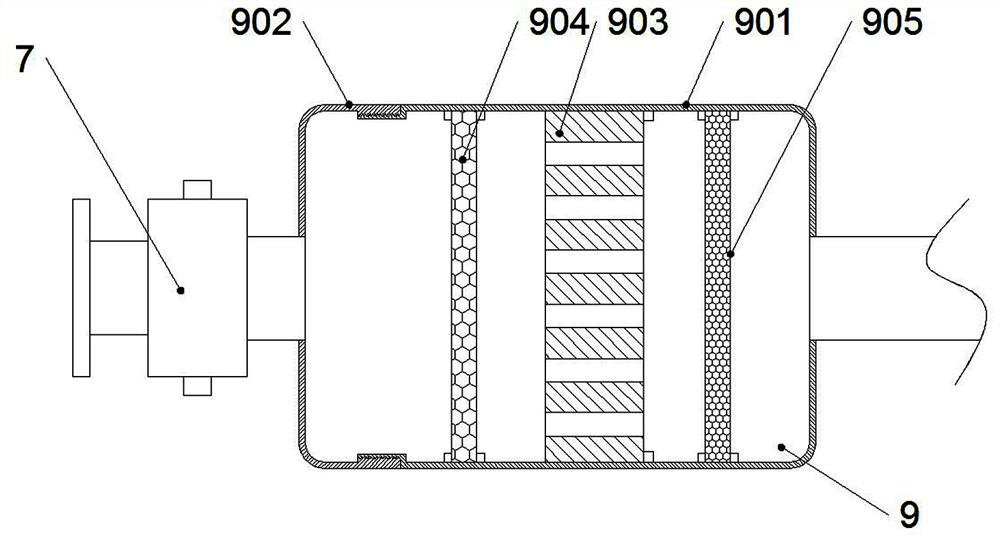

[0019] Example: such as Figure 1-3 As shown, a cooling device for a compressor of the present invention includes an installation base plate 1, a cooling tank 2 and a heat exchange tank 3 are fixedly installed on the top of the installation base plate 1, and a plurality of groups of fixing tanks are fixed horizontally inside the cooling tank 2. frame 201, and the bottom of each group of the fixed frames 201 are vertically fixed with a number of refrigeration fins 202, the inside of the heat exchange tank 3 is respectively fixed with tube plates 305 near both ends, and is covered by the tube plates 305 It is divided into a water inlet chamber, a heat exchange chamber and a water outlet chamber. There are multiple sets of heat exchange tubes 306 fixedly connected horizontally between the tube plates 305 . The cooling liquid inlet 301 and the hot oil inlet 302 are respectively fixedly installed on the side, and the left and right sides of the heat exchange tank 3 near the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com