Low temperature-seepage coupling dynamic impact compression experiment device for frozen rock-soil body

An experimental device and technology of rock and soil mass, applied in the field of dynamic shock compression, can solve the problems of indoor experimental research on dynamic shock compression characteristics of rock and soil without freezing, unable to truly reflect dynamic mechanical properties, and no research and development of frozen dynamic shock experimental device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

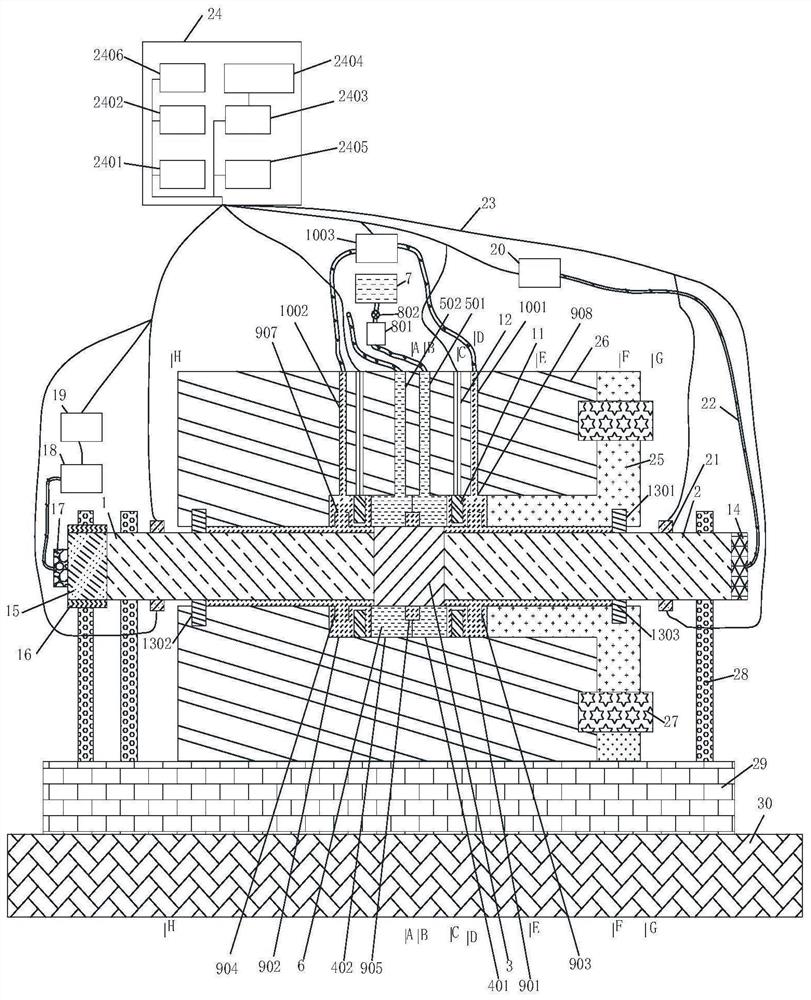

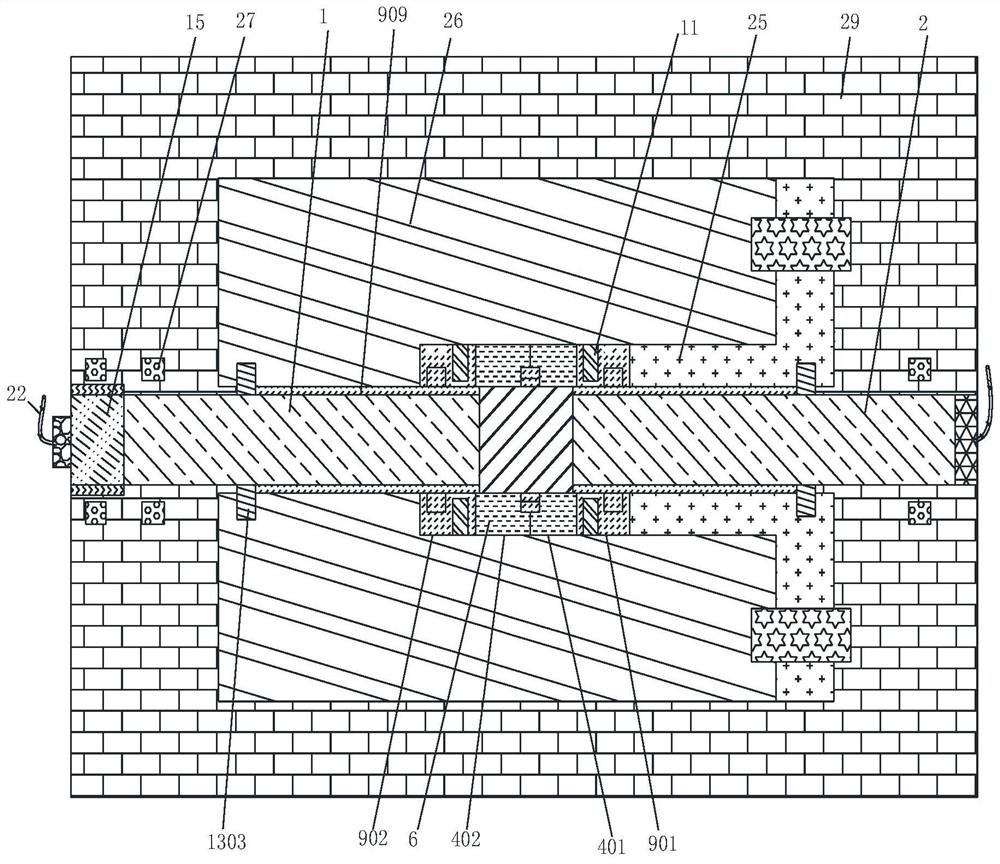

[0045] Design and implementation principle of the present invention are:

[0046] Generally speaking, the seepage field is constructed first, then the low-temperature temperature field is constructed, and finally the dynamic impact compression experiment of frozen rock and soil under the coupling of the seepage field and the low-temperature temperature field is carried out. details as follows:

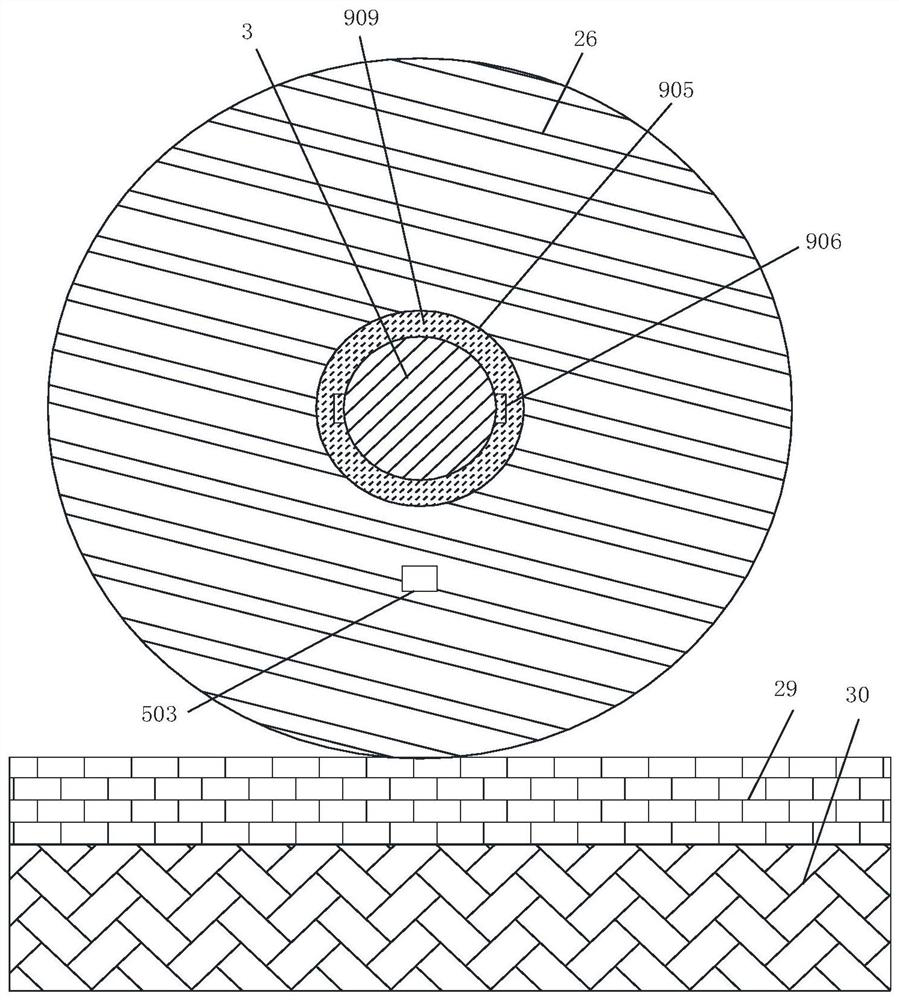

[0047] 1. Seepage field construction: through Hydraulic Loading and Storage Systems The water inlet hole 1001 in the hydraulic load storage system 9 injects pressurized pure water 909 into the first hydraulic storage hole 901 in the hydraulic load storage system 9, and then flows into the first water flow input groove 903 through the water jet hole 907, and then flows through the axial flow of the central axis The input tank 906 is sequentially input into the axial longitudinal water flow input tank 905 and the second water flow input tank 904, so that the pressurized pure water 909 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com