Method for calculating parameters of restriction orifice

A flow-limiting orifice and parameter calculation technology, which is applied in calculation, computer-aided design, electrical digital data processing, etc., can solve the problems of medium conveying accuracy decline, inability to fully adapt to different medium conveying states, etc., and reduce test time , the effect of improving the degree of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

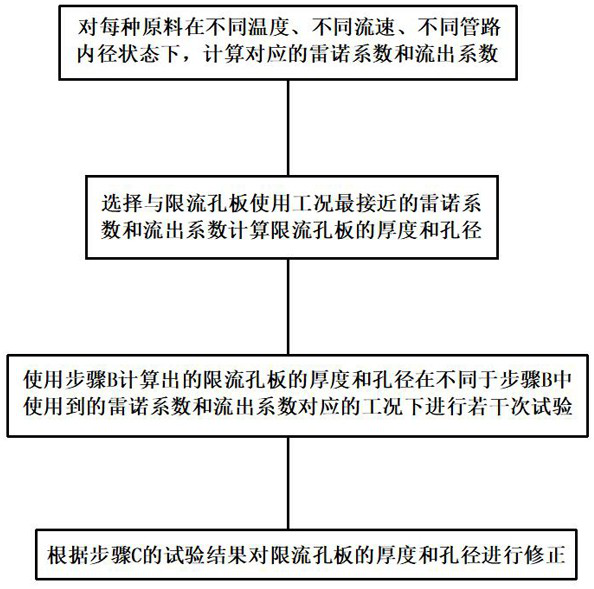

[0020] refer to figure 1 , a specific embodiment of the present invention comprises the following steps:

[0021] A. Calculate the corresponding Reynolds coefficient and outflow coefficient for each raw material at different temperatures, different flow rates, and different pipeline inner diameters;

[0022] B. Select the Reynolds coefficient and outflow coefficient closest to the working condition of the restricting orifice to calculate the thickness and aperture of the restricting orifice;

[0023] C, use the thickness and aperture of the flow-restricting orifice calculated in step B to carry out several tests under different working conditions corresponding to the Reynolds coefficient and the outflow coefficient used in step B;

[0024] D. Correct the thickness and aperture of the restrictor orifice according to the test results in step C.

[0025] In step A, there are no less than 3 calculation conditions for each raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com