Online turbidity automatic control system of filter

An automatic control system and filter technology, applied in the field of beer production, can solve the problems of inability to automatically detect beer turbidity, unable to meet the requirements of beer production, and high beer turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

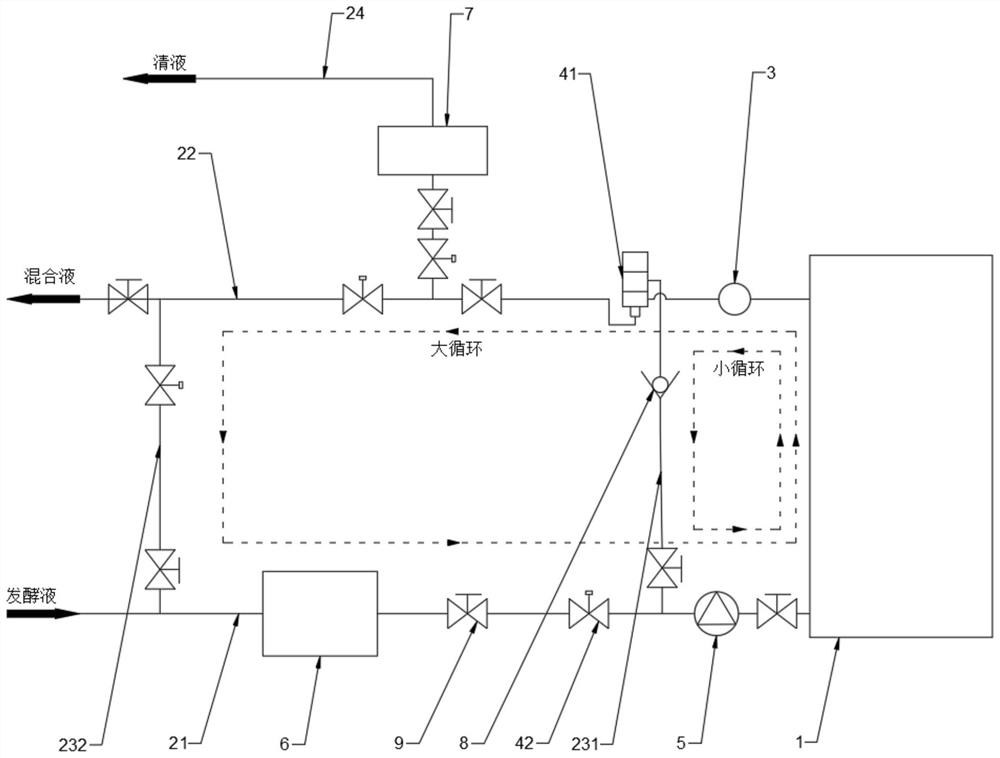

[0020] see figure 1 , in order to achieve the above object, the present invention provides a filter machine online turbidity automatic control system, including filter 1, liquid inlet pipeline 21, liquid outlet pipeline 22, return flow pipeline, turbidimeter 3, PLC controller, automatic valve and The metering pump 5 and the automatic valve are connected to the PLC controller; the liquid inlet pipe 21 and the liquid outlet pipe 22 are respectively connected to the filter 1, and a return pipe is connected between the liquid inlet pipe 21 and the liquid outlet pipe 22; the liquid is filtered by the filter machine 1 Finally, the turbidity meter 3 arranged on the liquid outlet pipeline 22 detects the liquid; when the turbidity is higher than the set value, the turbidity meter 3 feeds back a signal to the PLC controller, and the PLC controller controls the automatic valve to make the liquid enter the inner Circulation, the liquid filtered by the filter 1 passes through the liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com