Batching device for producing electromagnetic shielding composite fiber membrane

A composite fiber film, electromagnetic shielding technology, used in mixers, transportation and packaging, mixer accessories and other directions, can solve problems such as unfavorable rapid production, inability to achieve, poor grinding effect, etc., to save manpower and ensure grinding requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

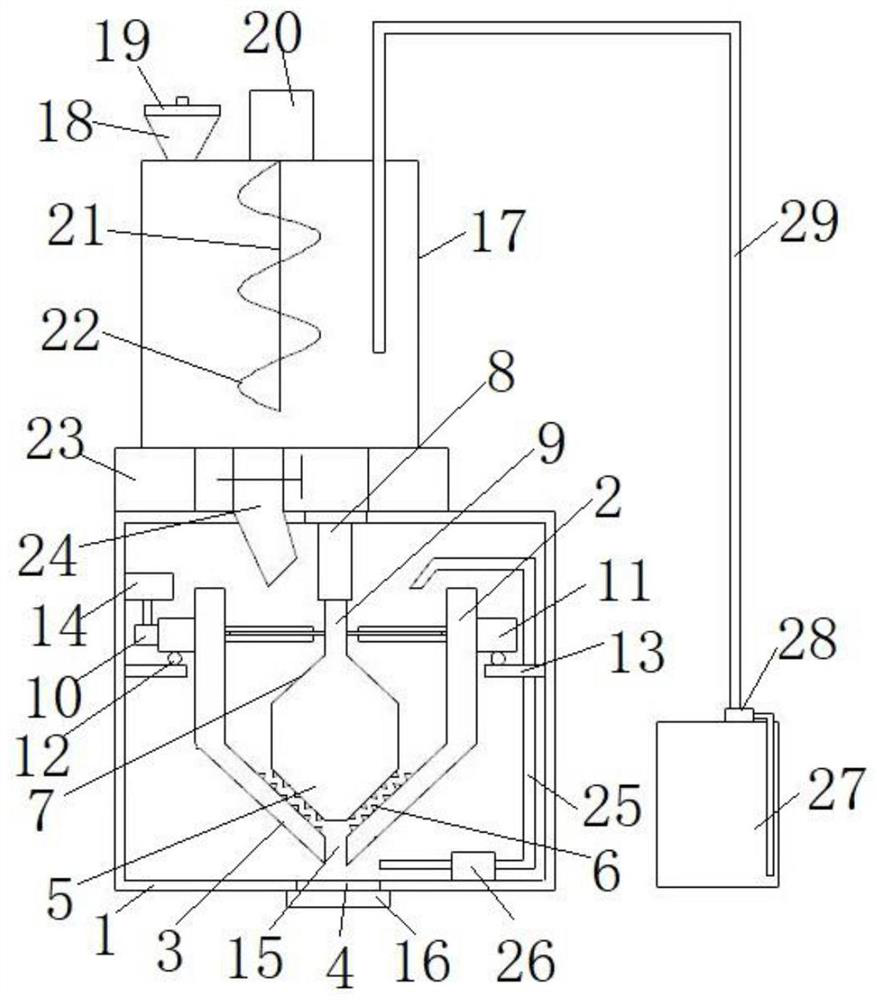

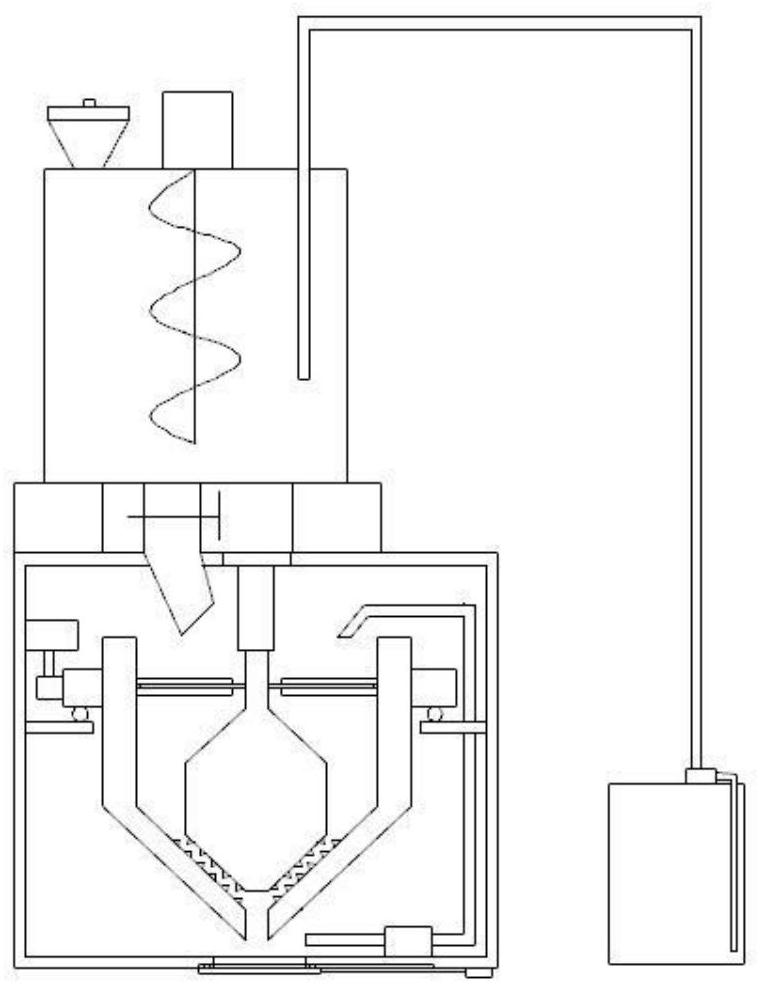

[0031] Such as figure 1 As shown, in this embodiment, the grinding mechanism includes a housing 1, a cylinder 2 disposed in the housing 1, and a crushing head 3 disposed at the lower end of the cylinder 2 and coaxially arranged with the cylinder 2, and the top of the housing 1 There is a suspension feed port, the bottom of the shell 1 is provided with a discharge port 4 that can be opened and closed, the bottom of the crushing head 3 is provided with a grinding liquid outlet 15 pointing to the discharge port 4, and the upper end opening of the cylinder body 2 is located at Below the feeding port of the suspension of the casing 1, the crushing head 3 is provided with a grinding head 5 cooperating with the crushing head 3, the inner wall of the crushing head 3 is provided with a first auger blade 6, and the upper side of the grinding head 5 is provided with a The suspension is introduced into the guide structure 7 of the crushing head 3, the guide structure 7 is rotationally con...

Embodiment 2

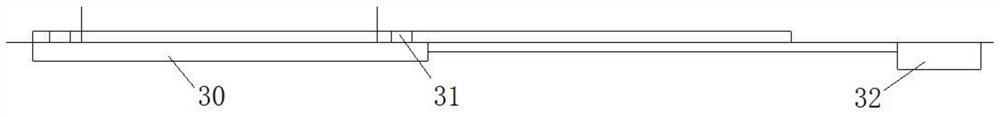

[0042] Such as figure 2 and image 3 As shown, the difference between this embodiment and Embodiment 1 is that the discharge port is sealed by a blocking and sealing mechanism that can move laterally to open and close the discharge port. In this embodiment, the shielding and sealing mechanism includes a sealing baffle 30, a slider 31 and an electric push rod 32 arranged at the bottom of the housing. The bottom of the housing is provided with a chute, and the sealing baffle is slidably connected to the chute through the slider. The telescopic end of the electric push rod is connected to one side of the sealing baffle through fasteners. Under normal conditions, the sealing baffle is covered at the discharge port to realize the sealing of the discharge port and avoid the discharge of the material inside the shell. When opening the discharge port, start the electric push rod, and the electric push rod will produce a contraction movement, which will drive the sealing baffle to mo...

Embodiment 3

[0044] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the batching device for producing the electromagnetic shielding composite fiber film also includes a second mixing mechanism, which is connected to the solvent delivery mechanism through a branch pipe 35 . In the present embodiment, the second mixing mechanism includes a second mixing tank 33 and a second stirring mechanism arranged in the second mixing tank 33, and the second mixing tank 33 is provided with a silane coupling agent and grinding After the second graphite feed hopper 34 and the second solvent feed port. The first solvent and the second solvent are the same solvent. A second cover is provided on the second feeding hopper to prevent sundries from entering the second feeding hopper.

[0045] The second stirring mechanism comprises a second stirring motor 36, a second stirring shaft 37 disposed in the second mixing tank 33 and a first stirring blade 38 disposed on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap