Desilting device for furniture wood preservation

A wood antiseptic and dredging device technology, which is applied to heating devices, wood treatment, impregnated wood, etc., can solve the problems of cumbersome operation steps, time-consuming and desilting and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

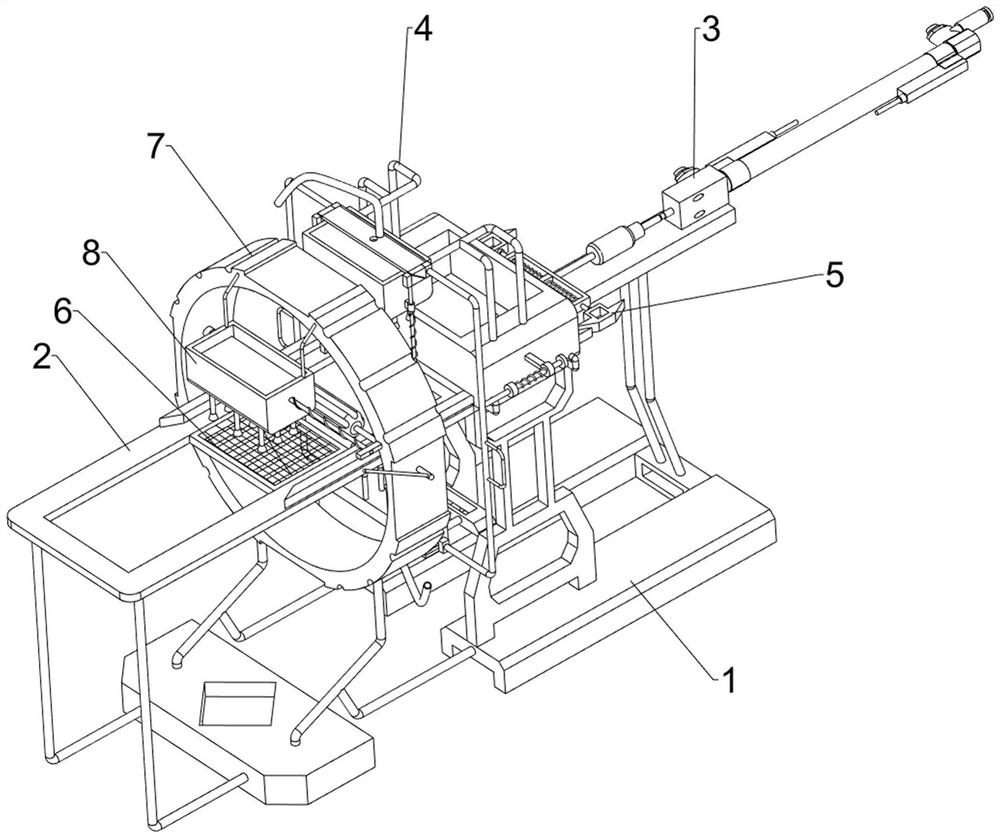

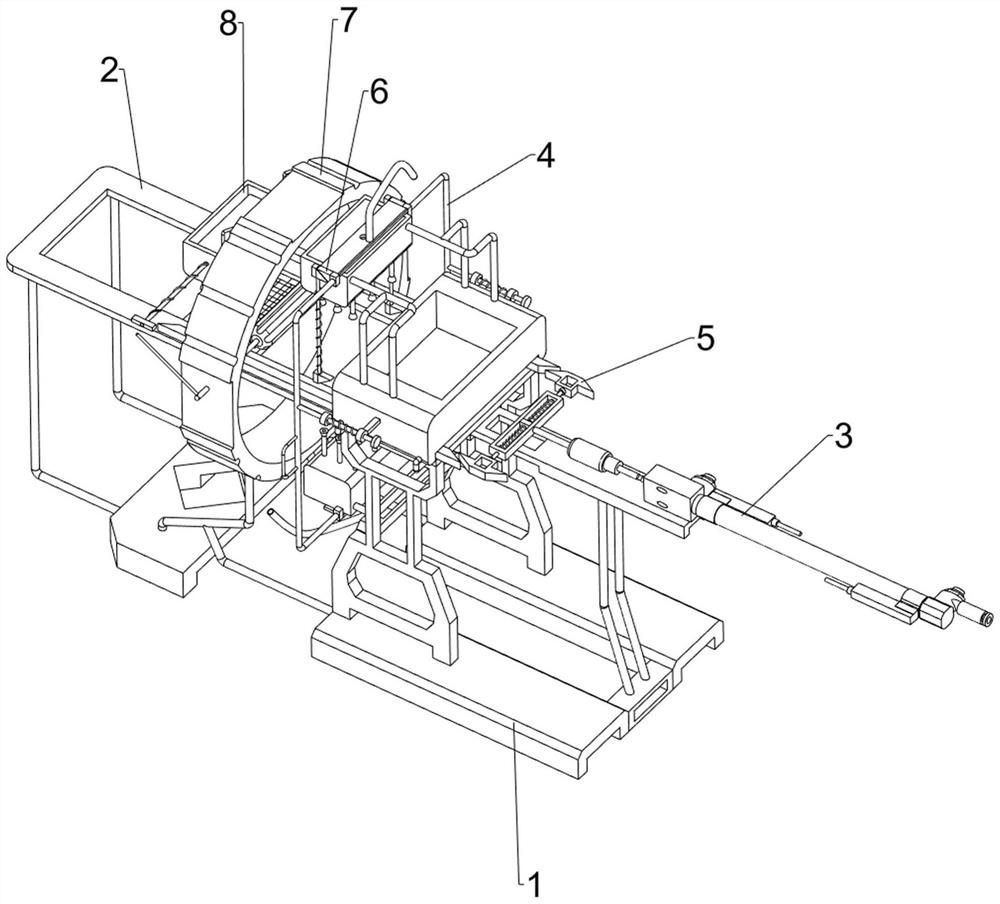

[0064] A kind of dredging device for furniture wood anticorrosion, such as figure 1 and figure 2 As shown, it includes a base 1, a placement frame 2, a pushing mechanism 3 and a dredging mechanism 4. The upper front side of the base 1 is provided with a placement frame 2, the upper rear side of the base 1 is provided with a pushing mechanism 3, and the front side of the middle part of the placement frame 2 The side and the top of the pushing mechanism 3 are provided with a dredging mechanism 4 .

[0065]When people need to dredge the dust and dirt on furniture wood, this dredging device can be used. At first, the timber is placed on the rack 2 at the pushing mechanism 3, and clear water is filled in the dredging mechanism 4, and then Start the pushing mechanism 3, the pushing mechanism 3 pushes the wood to the dredging mechanism 4, open the dredging mechanism 4, spray water on the dredging mechanism 4 to desilt the wood, and close the dredging mechanism 4 and the pushing mec...

Embodiment 2

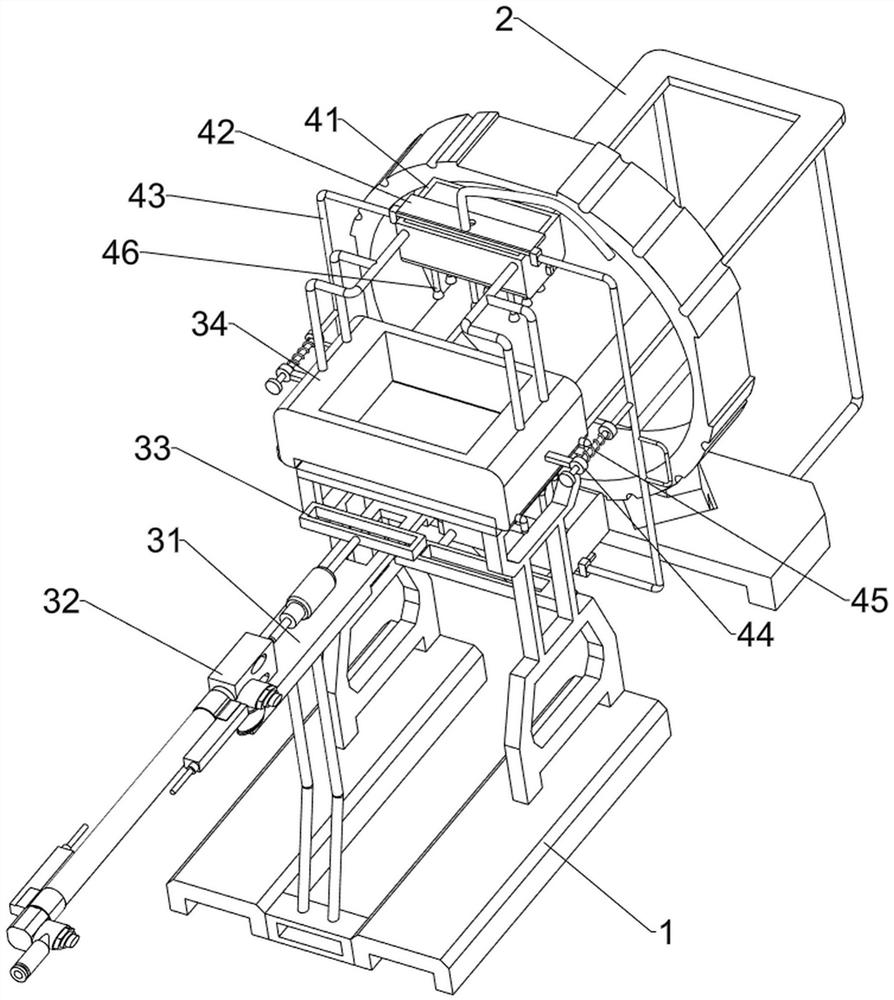

[0067] On the basis of Example 1, such as image 3 As shown, the pusher mechanism 3 includes a fixed seat 31, a brake cylinder 32, a push block 33 and a discharge rack 34, the upper rear side of the base 1 is provided with a fixed seat 31, and the top of the fixed seat 31 is equipped with a brake cylinder 32. The telescopic rod of moving cylinder 32 is provided with push block 33, and the rear side of placing frame 2 top is provided with material discharging frame 34.

[0068] People stack multiple pieces of wood into the discharge rack 34, and then open the brake cylinder 32. The extension of the brake cylinder 32 drives the push block 33 to move forward, thereby pushing a piece of wood forward to achieve the effect of intermittently pushing wood , when the brake cylinder 32 shortens and drives the push block 33 to move backward and reset, the brake cylinder 32 is closed.

[0069] The dredging mechanism 4 includes a water storage tank 41, a water retaining plate 42, a slidin...

Embodiment 3

[0072] On the basis of Example 2, such as Figure 4-7 As shown, a positioning mechanism 5 is also included, and the positioning mechanism 5 includes a first fixed plate 52, a telescopic rod 53, a first wedge block 54, a second spring 55 and a second wedge block 56, and the push block 33 has a rectangular groove 51, the middle part of the inner side of the push block 33 is provided with a first fixed plate 52, the left and right sides of the first fixed plate 52 are connected with a telescopic rod 53, the telescopic rod 53 passes through the push block 33, and the outer end of the telescopic rod 53 is provided with a first wedge block 54, the telescopic rod 53 is wound with a second spring 55, and the two ends of the second spring 55 are respectively connected with the first fixed plate 52 and the telescopic rod 53, and the left and right sides of the top of the rack 2 are provided with a second wedge-shaped block 56, and the second The wedge block 56 is in contact with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com