Structure for preventing adhesive tape from curling of carton sealer

A technology of box sealer and tape, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., and can solve problems such as inconvenient use, inconvenient picking, and easy rewinding of tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

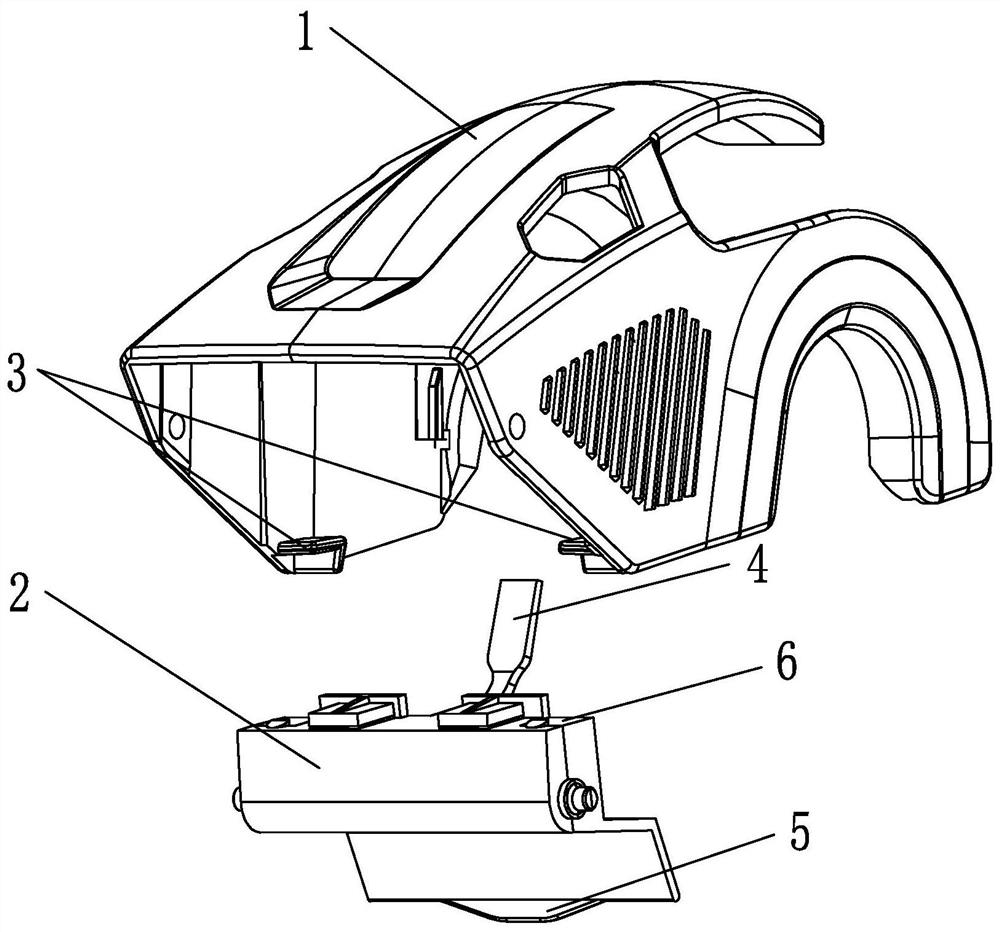

[0025] Embodiment 1: as Figure 1-3 As shown, the anti-tape curling structure of the box sealer of the present invention includes a box sealer 1 provided with cutting teeth 6, a whole roll of adhesive tape is embedded inside the box sealer 1, and the central hole of the adhesive tape is aligned with the positioning shaft of the box sealer 1 Embedded, free to rotate circumferentially when the tape is pulled. The opening of the box sealer 1 is provided with a pressure tape plate 2, the pressure tape plate 2 is a lever, and the fulcrum is rotatably connected to the inner sides of the opening of the case sealer 1; the outer end of the pressure tape plate 2 is the power The arm is located on the outside of the opening and is attached to the two brackets 3 inside the opening of the box sealer 1; the inner end of the pressure belt plate 2 is a resistance arm, located on the inside of the opening and provided with a One end is against the inner side of the box sealer 1; the outer end...

Embodiment 2

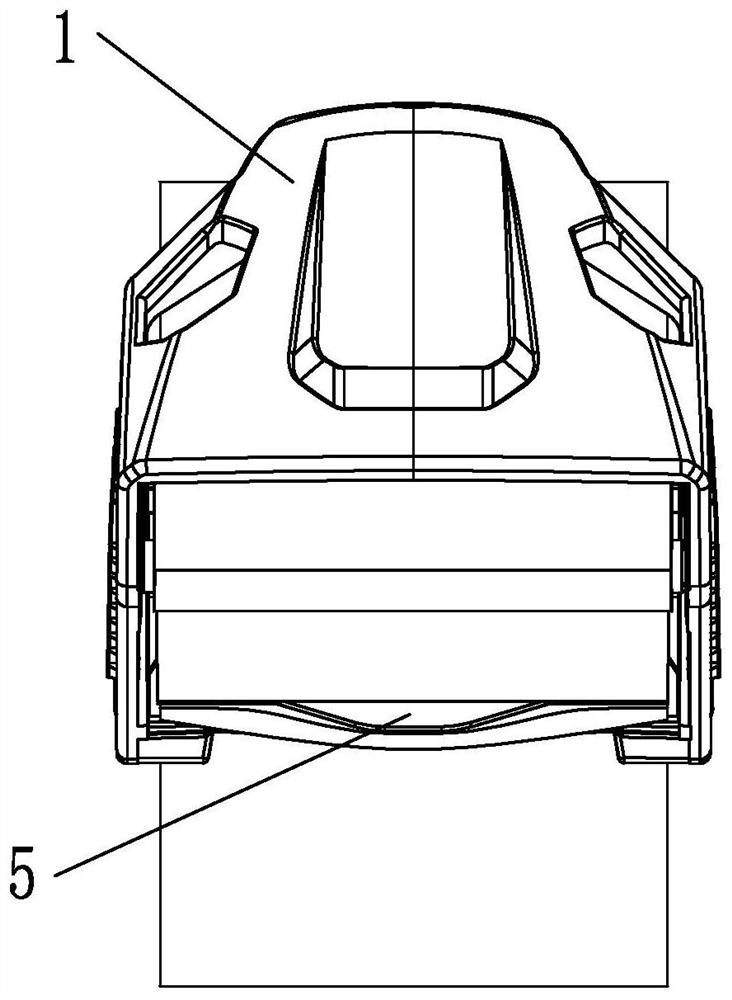

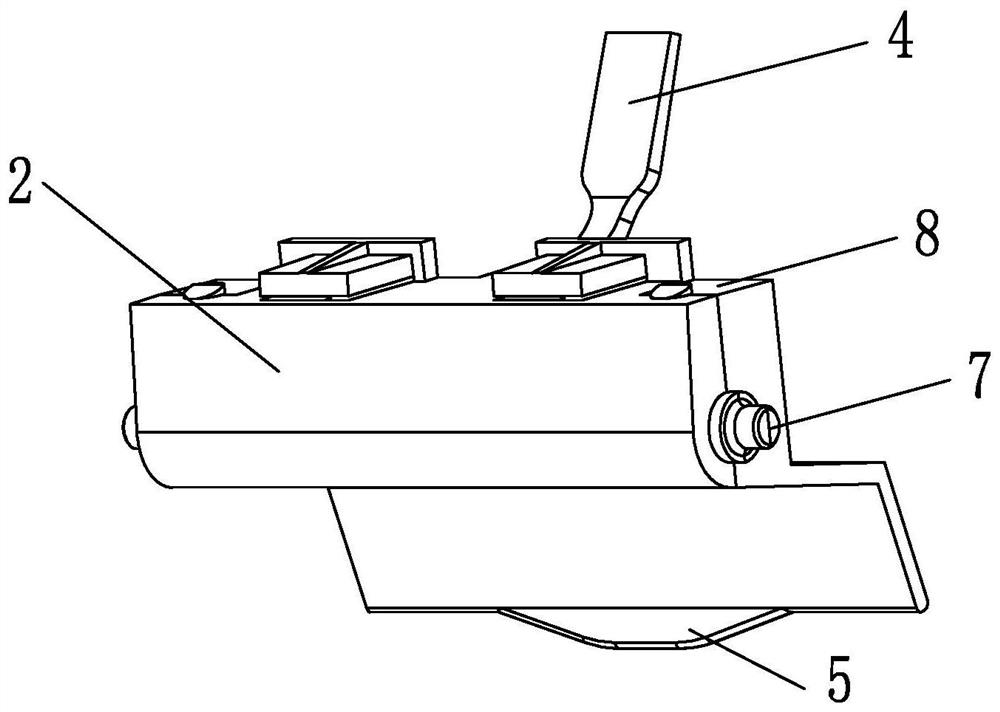

[0026] Embodiment 2: as Figure 4 with Figure 5 As shown, the anti-tape curling structure of the box sealer of the present invention includes a box sealer 1 provided with cutting teeth 6, a whole roll of adhesive tape is embedded inside the box sealer 1, and the central hole of the adhesive tape is aligned with the positioning shaft of the box sealer 1 Embedded, free to rotate circumferentially when the tape is pulled. The pressure tape plate 2 and the box sealer 1 are integrally structured, relying on its own elastic rebound, the pressure tape plate 2 is a piece of elastic element, and the inner end of the pressure tape plate 2 is fixed on the inner side of the opening of the box sealer 1, The both sides of the outer end of described pressing tape plate 2 extend to two supporting blocks 3 and form the passage that adhesive tape passes through, and the middle part of the outer end of described pressing tape plate 2 is provided with projection 5, and adhesive tape is from pre...

Embodiment 3

[0027] Embodiment 3: as Image 6 As mentioned above, the anti-tape curling structure of the box sealer of the present invention includes a box sealer 1 provided with cutting teeth 6, a whole roll of adhesive tape is embedded inside the box sealer 1, and the central hole of the tape is connected to the positioning shaft of the box sealer 1. Embedded, free to rotate circumferentially when the tape is pulled. The pressure tape plate 2 and the box sealer 1 are integrally structured, relying on its own elastic rebound, the inner end of the pressure tape plate 2 is fixed on the inner side of the opening of the box sealer 1, and both sides of the pressure tape plate 2 are connected to the box sealer 1. There is a distance between the brackets 3 on the same side, and the adhesive tape passes through the upper planes of the two brackets 3 and bends against the bumps 3 .

[0028] The working principle of the present invention: after the tape is pulled out and cut, the pressure tape pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com