Root crop harvester

A technology for rhizome crops and harvesters, which is applied to harvesters, digging harvesters, excavators, etc., can solve the problems of poor soil screening effect and root crops rolling back, so as to improve the screening effect and reduce the resistance. Small, the effect of improving the screening capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

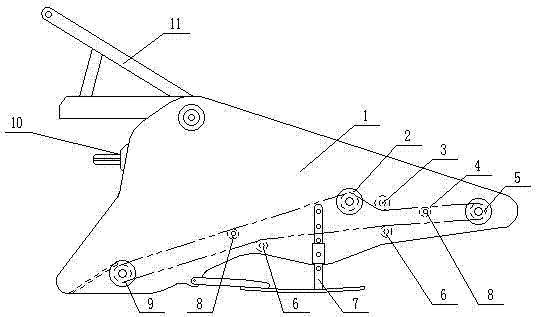

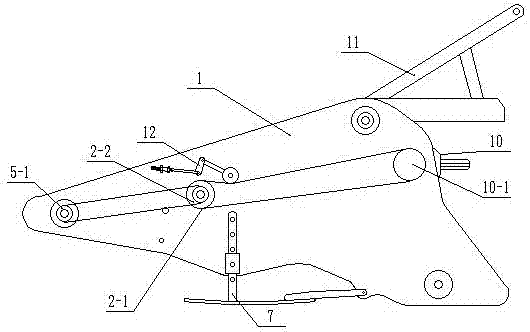

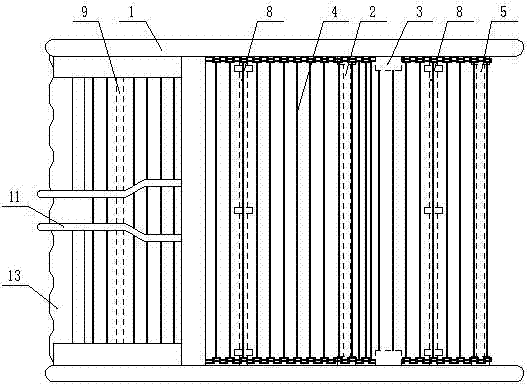

[0022] Such as Figure 1-6 The shown rhizome crop harvester comprises a frame 1, a blade 13 and a conveyor arranged on the rear side of the blade 13, and the conveyor includes a ring-type sieve conveyor belt 4, a supporting front axle 9 supported on the front end of the conveyor belt 4 And the supporting rear shaft 5 supported on the rear end of the conveyor belt 4, the endless conveyor belt 4 includes two endless conveyor chains and connecting rods densely arranged between the two circular conveyor chains, and the two connecting rods of each connecting rod The ends are respectively connected to two endless conveyor chains, and there is a gap between adjacent connecting rods. The conveyor also includes a supporting intermediate shaft 2 that supports the middle of the conveying surface of the conveyor belt 4, and the supporting intermediate shaft 2 is higher than the supporting front shaft. 9. The two pressure sprockets 3 are located behind the supporting intermediate shaft 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com