Novel gravity multi-disc thickener

A multi-disk, thickener technology, applied in the direction of paper recycling, pulp dehydration, process efficiency improvement, etc., to achieve the effect of reducing pressure concentration, ensuring effect and life, and large dehydration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

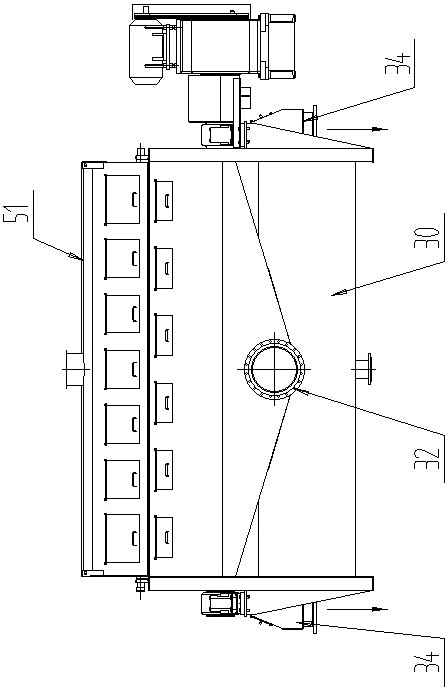

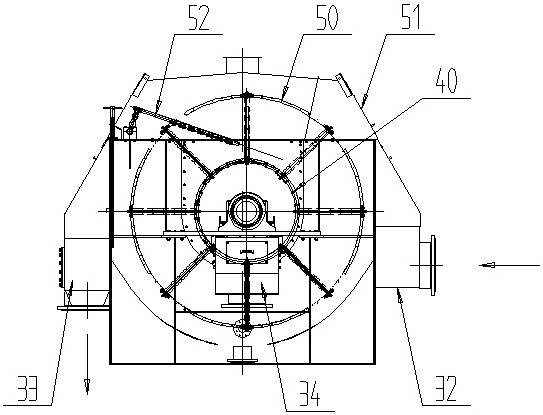

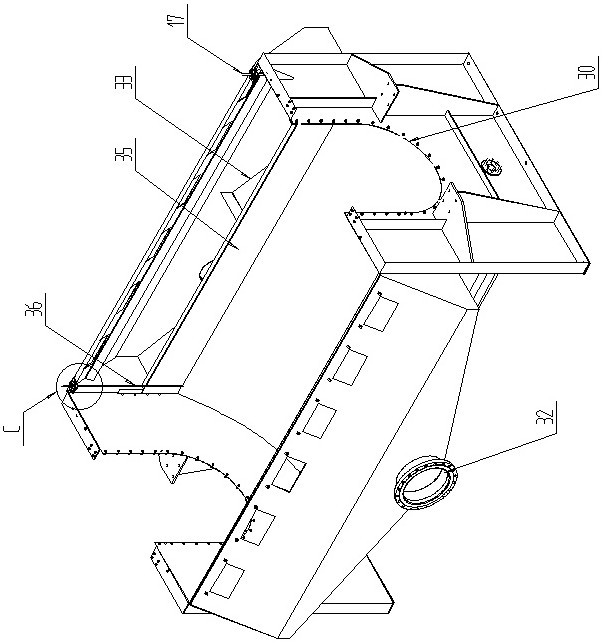

[0037] Such as Figure 1 to Figure 12 As shown, this embodiment discloses a novel gravity multi-disc concentrator, which includes a tank body 30 and a hollow main shaft 40 installed on the tank body 30 , and the tank body 30 is oppositely arranged with feeding hoppers on both sides of the hollow main shaft 40 32, the discharge hopper 33, and the axial ends of the hollow main shaft 40 are respectively provided with filtrate outlet boxes 34.

[0038] The tank body 30 includes a semi-cylindrical part and side plates connected on both sides of the semi-cylindrical part and extending upwards. The two ends of the semi-cylindrical part are respectively provided with tank body end plates 13, and the hollow main shaft 40 is coaxially arranged in the semi-cylindrical part. The bucket 32 and the discharge hopper 33 are respectively loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com