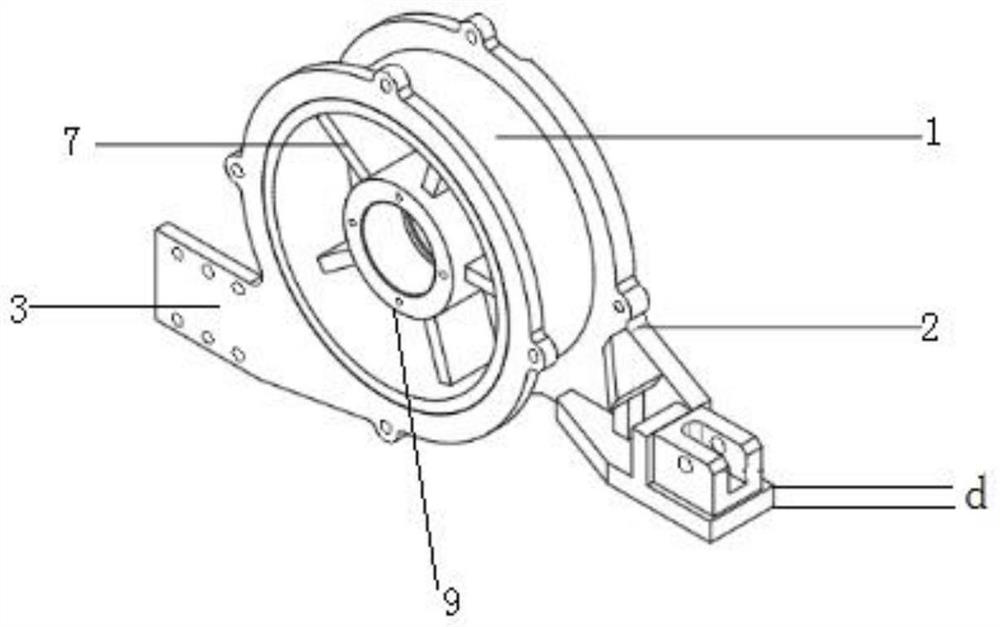

Integrally reinforced dead rope fixer

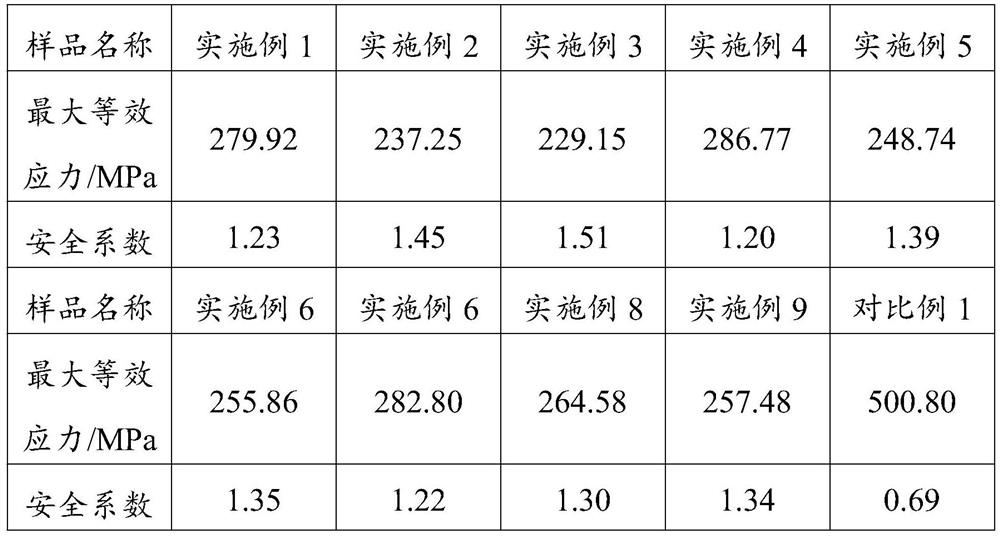

A fixer and dead line technology, applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of dead line fixer sheave, sensor arm with complex shape, increase in manufacturing cost, etc., to optimize size, improve Safety factor, the effect of reducing the maximum equivalent stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides an enhanced dead-rope fixer, the thickness of the rib plate of the sheave, the thickness of the wall of the sheave, the transition fillet radius of the sensor support arm and the thickness of the sensor support arm are shown in Table 1.

[0020] Parts dimensions of Table 1 Embodiment 1

[0021] Parts Size / mm Sheave rib thickness 25 Sheave wall thickness 40 Sensor Arm Transition Fillet Radius 120 Sensor Arm Thickness 40

Embodiment 2

[0023] This embodiment provides an enhanced dead-rope fixer, the thickness of the rib plate of the sheave, the thickness of the wall of the sheave, the transition fillet radius of the sensor support arm and the thickness of the sensor support arm are shown in Table 2.

[0024] Parts size of table 2 embodiment 2

[0025] Parts Size / mm Sheave rib thickness 30 Sheave wall thickness 44 Sensor Arm Transition Fillet Radius 120 Sensor Arm Thickness 45

Embodiment 3

[0027] This embodiment provides an enhanced dead-rope fixer, the thickness of the rib plate of the sheave, the thickness of the wall of the sheave, the transition fillet radius of the sensor support arm and the thickness of the sensor support arm are shown in Table 3.

[0028] Parts size of table 3 embodiment 3

[0029] Parts Size / mm Sheave rib thickness 35 Sheave wall thickness 50 Sensor Arm Transition Fillet Radius 120 Sensor Arm Thickness 50

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com