Prefabricated clear water-sewage separation side type ditch inspection well and cover plate

A technology for inspection wells and cover plates, which is used in drainage, safety devices, mining equipment, etc., can solve the problems of occupying driving width, affecting vehicle traffic, affecting tunnel vehicle traffic, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

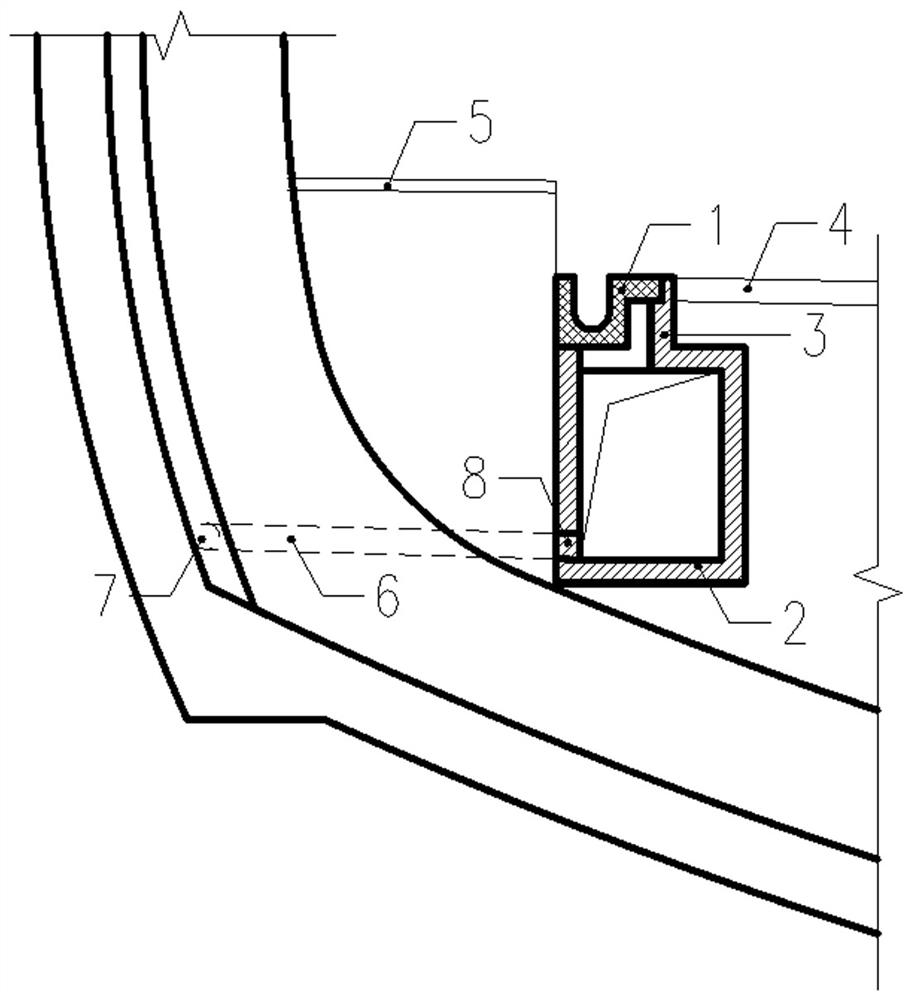

[0018] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

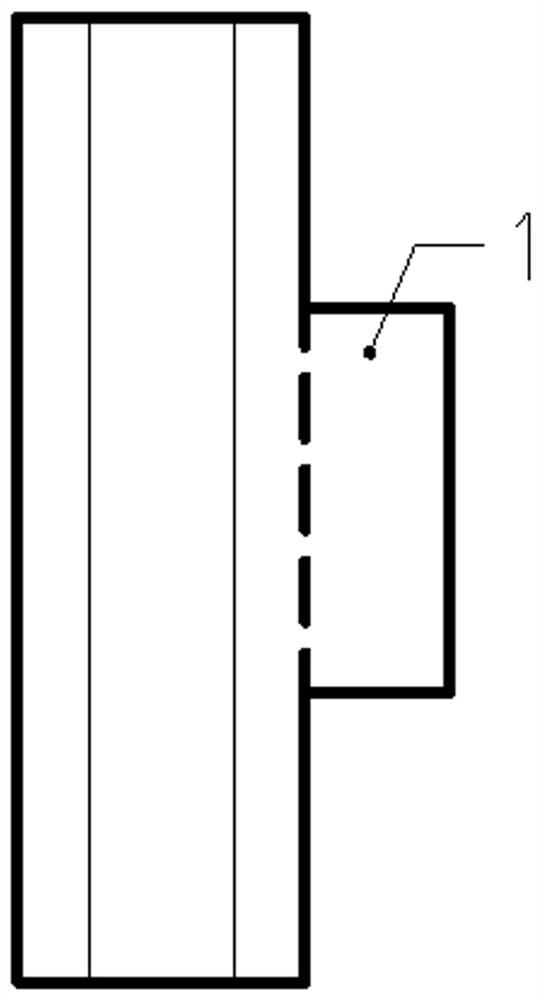

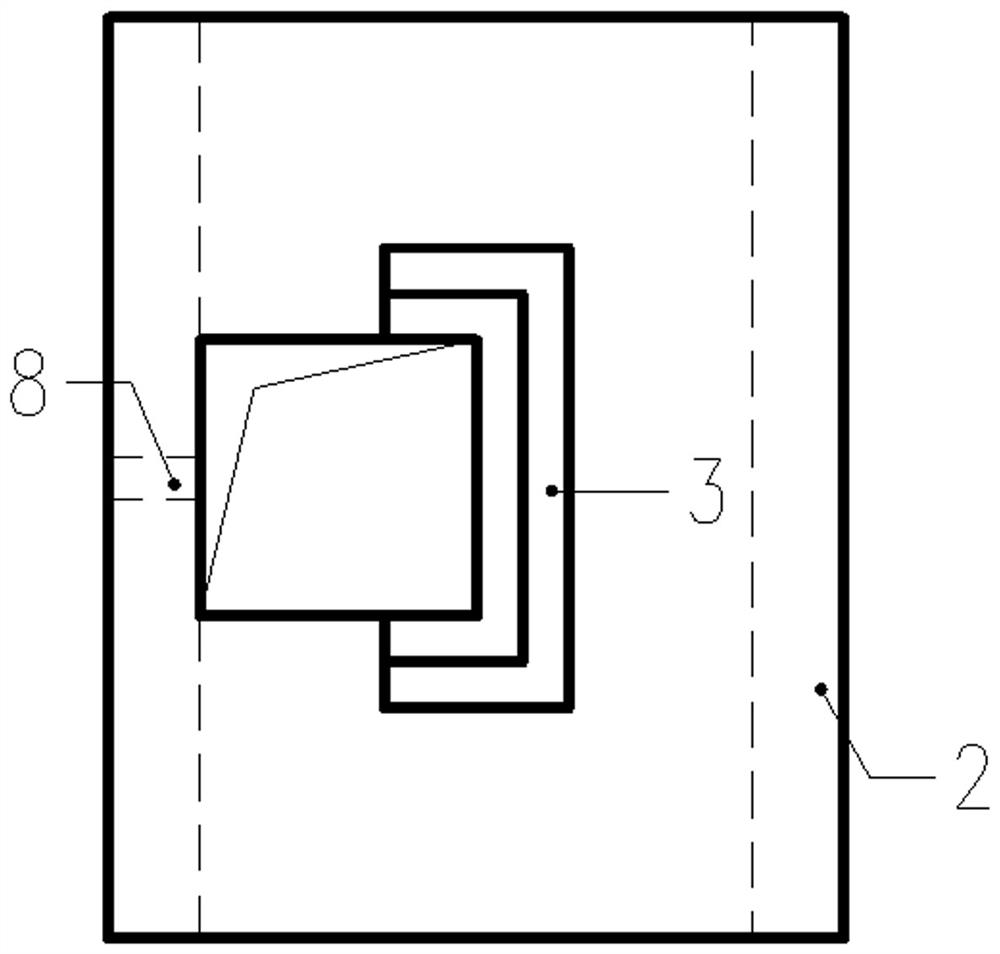

[0019] refer to Figure 1-4 As shown, a prefabricated sewage cleaning and separation side ditch inspection well and cover plate that does not occupy the width of the lane in the tunnel, including a prefabricated inspection well 2 and a prefabricated special-shaped inspection well cover plate 1 that doubles as a sewage discharge side ditch.

[0020] Tunnel roadside inspection road 5 is arranged on the outside of tunnel roadway 4, and the prefabricated inspection shaft 2 is arranged under the tunnel roadside inspection road 4, and is set close to the tunnel roadside inspection road 5, and the inspection well head 3 is arranged between the tunnel roadway and the tunnel roadside inspection road In between, the lower part of the prefabricated inspection we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com