Model support and coupled roll drive device for unsteady dynamometric wind tunnel tests

A technology of wind tunnel test and drive device, which is applied in the direction of measurement device, aerodynamic test, machine/structural component test, etc. Motor accuracy and other issues to achieve the effect of improving accuracy, improving adaptability, and increasing usable length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

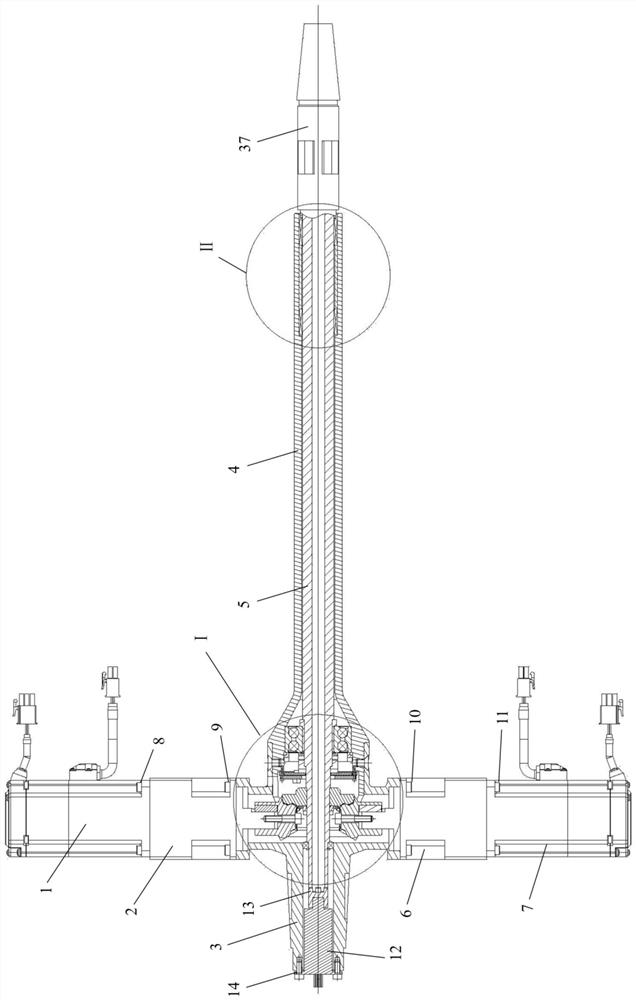

Method used

Image

Examples

Embodiment 1

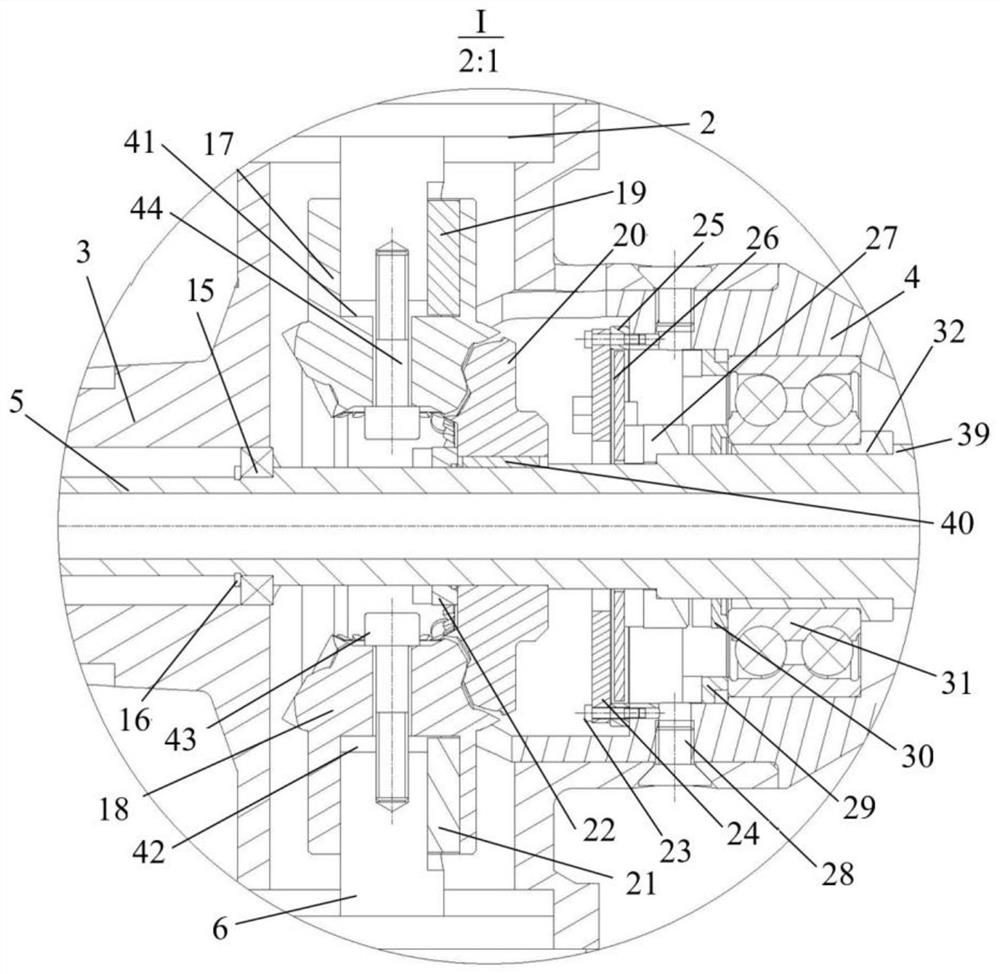

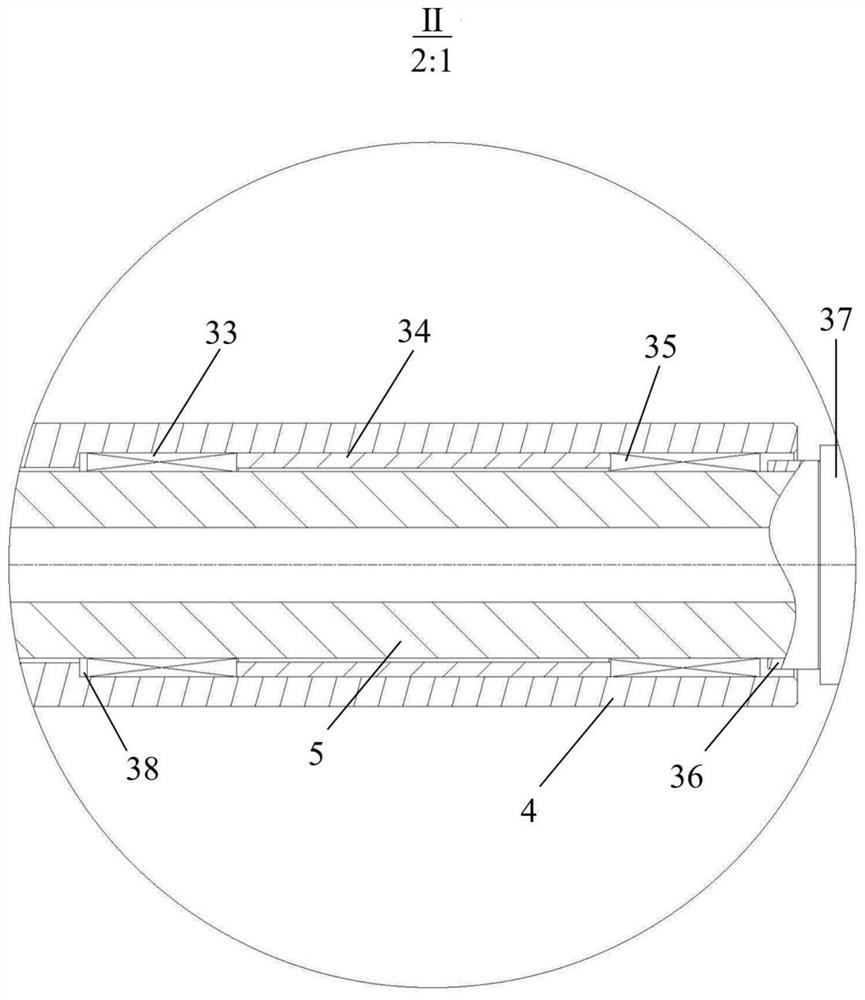

[0034] The installation process of this embodiment is as follows:

[0035] Insert the front retaining ring 36 from the small-diameter end of the mandrel 5, that is, the rear end, until it contacts the rear end of the balance 37, and install the needle roller bearing I35, bushing I34, and needle roller bearing II33 successively in the same installation method, and the front retaining ring 36. Needle roller bearing I35, shaft sleeve I34, needle roller bearing II33 and mandrel 5 all have clearance fits to ensure flexible rotation of the above parts. The rear end of the mandrel 5 penetrates from the small diameter end of the tail rod 4, that is, the front end, until the needle bearing II33 contacts with the front end 38 of the tail rod 4.

[0036] The inner circle of the thrust bearing 31 is in transition fit with the outer cylinder of the shaft sleeve II 32, the front end surface of the thrust bearing 31 fits the rear end surface of the boss of the shaft sleeve II 32, and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com