Method and single crystal furnace for preparing n-type single crystal silicon

A single crystal silicon, n-type technology, applied in the field of preparing n-type single crystal silicon, can solve the problems of increasing the usable length, changing the crystal resistivity, and short usable length of lightly doped n-type single crystal silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

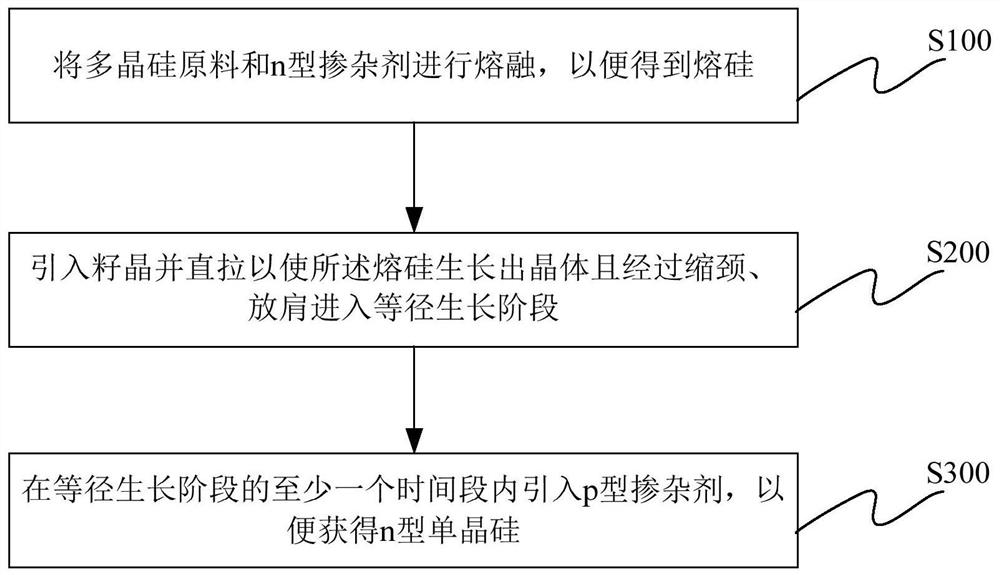

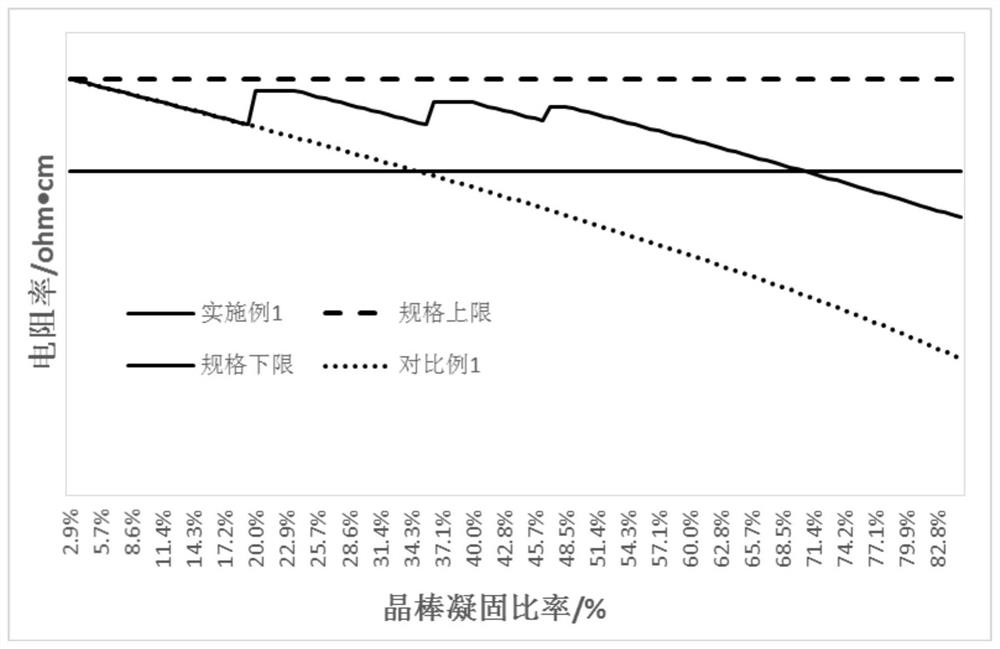

[0066] (1) Melt polysilicon raw material and n-type dopant to obtain molten silicon. The mass of polysilicon raw material is 250kg, and the doping amount of n-type dopant is 0.62g, according to the normal chemical process.

[0067] (2) introducing a seed crystal and pulling it straight so that the molten silicon grows into a crystal and goes through the stages of necking, shouldering, and equal diameter growth;

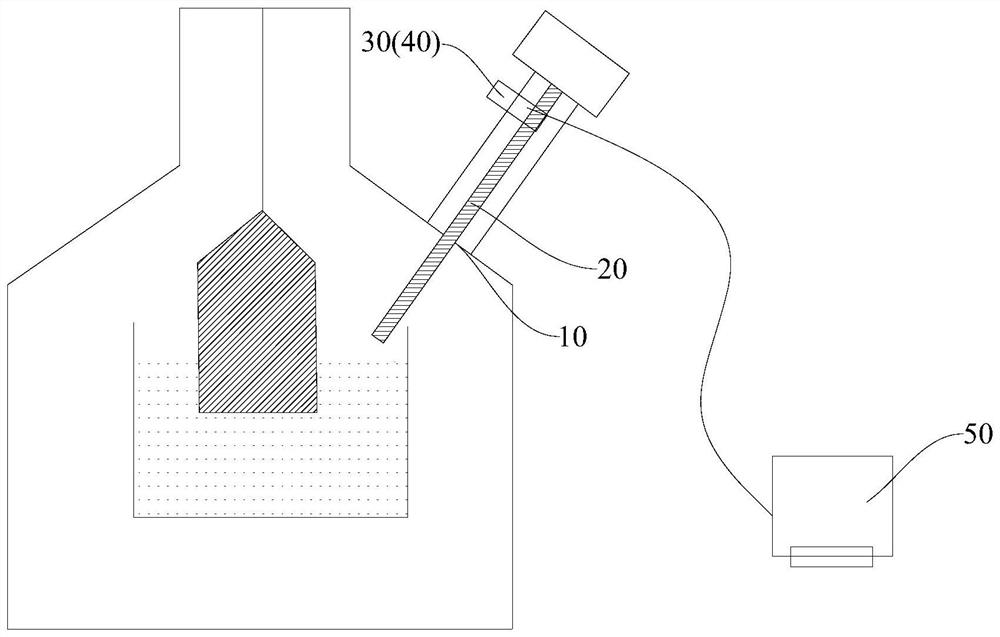

[0068] (3) Diborane is passed into the single crystal furnace in the 6th hour, the 12th hour, and the 20th hour when the equal-diameter growth stage begins. The concentration of diborane is 500ppm, and the gas flow rate of feeding diborane is 300sccm , the access time is 1 minute.

[0069] (4) Obtain n-type single crystal silicon.

Embodiment 2

[0071] (1) Melt the polysilicon raw material and n-type dopant to obtain molten silicon. The mass of polysilicon raw material is 250kg, and the doping amount of n-type dopant is 0.67g, according to the normal chemical process.

[0072] (2) introducing a seed crystal and pulling it straight so that the molten silicon grows into a crystal and goes through the stages of necking, shouldering, and equal diameter growth;

[0073] (3) in the 3rd hour, the 9th hour, the 15th hour, the 23rd hour in the equidiametrical growth stage, pass into diborane in the single crystal furnace, the concentration of diborane is 300ppm, pass into diborane The gas flow rate is 100 sccm, and the passing time is 0.5-1 minute.

[0074] (4) Obtain n-type single crystal silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com