PCB of plunger type intank urea pump controller and wiring method thereof

A wiring method and a urea pump technology, which are applied in printed circuit making wiring diagrams, printed circuit manufacturing, printed circuits connected with non-printed electrical components, etc., can solve problems such as crystal oscillator wiring other signal interference, program errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

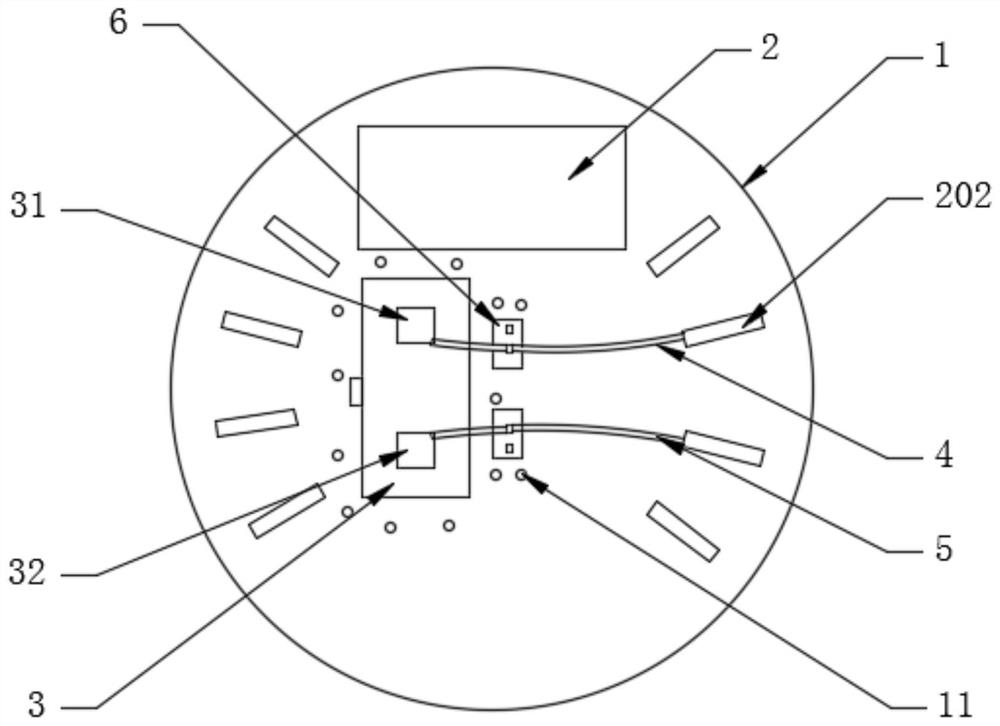

[0033] see figure 1 , a plunger type intank urea pump controller PCB, PCB1 is provided with a microprocessor 2, a crystal oscillator 3, a signal line 4 and a signal line 2 5, and the microprocessor 2 includes a pin 21 and a pin 2 22; the crystal oscillator 3 includes a first pin 31 and a second pin 32; the signal line one 4 connects the first pin 21 to the first pin 31; the signal line two 5 connects the The second pin 22 is connected to the second pin 32; The lengths of the traces between them should be approximately equal, that is, the lengths of the first signal line 4 and the second signal line 5 are approximately equal, and the first signal line 4 and the second signal line 5 are arranged as arcs, so that all The signal provided by the crystal oscillator 3 is more stable;

Embodiment 2

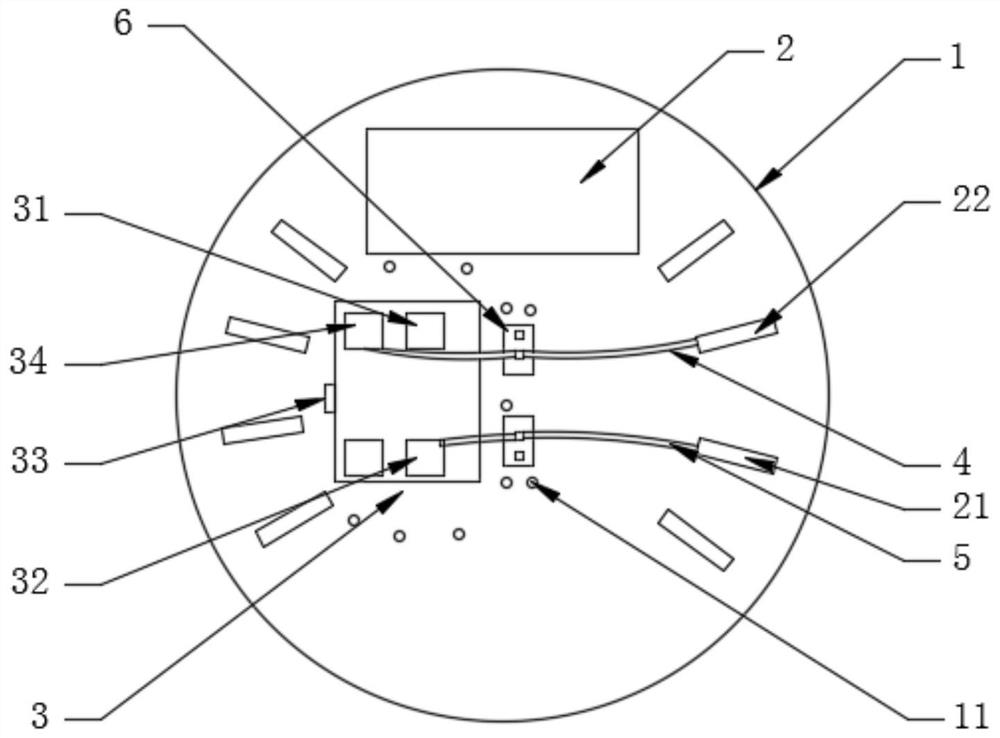

[0035] see figure 2 , figure 2 It is a structural schematic diagram of another embodiment of the PCB of the plunger type intank urea pump controller PCB of the present invention, since the linear distance between the first pin 21 and the first pin 31 is different from that between the pin two 22 to The straight-line distances between the two pins 32 are not equal, therefore, to achieve equal lengths of the signal line one 4 and the signal line two 5, they can be arranged as follows figure 2 The arc shown in Fig. The range of interference can be further narrowed. Compared with the right-angle routing in the prior art, the signal line 1 4 and the signal line 2 5 in the embodiment both follow an arc, which can make the signal transmission effect better;

[0036] In this embodiment, the microprocessor 2 and the crystal oscillator 3 are reasonably wired on the PCB 1 to prevent the signal from being disturbed, so that the plunger type intank urea pump controller PCB frequency,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com