Measurement control device, packaging device equipped with said measurement control device, and measurement control method

A technology of measurement control and quantity control, applied in measuring devices, conveyor control devices, packaging, etc., can solve problems such as difficult film packaging, "appearance" deterioration, and the inability to accurately detect the G length of the packaged object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

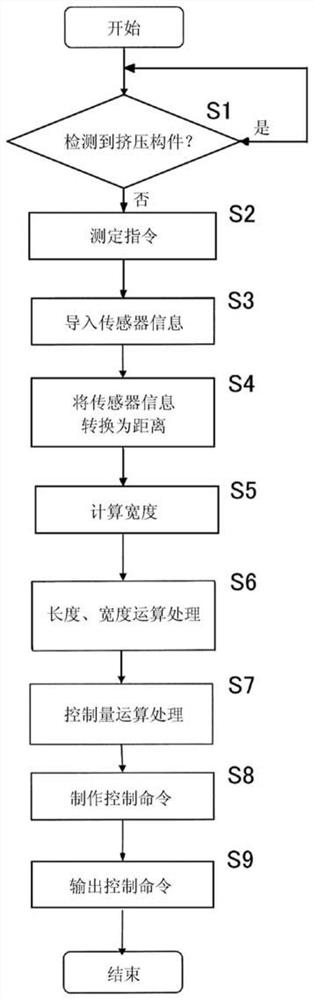

[0132] Image 6 It shows an example of the processing operation of the computing unit 21 of the measurement control device according to the embodiment.

[0133] First, in step S11, the introduction of the information signal from the sensor unit 1 is started.

[0134] When the introduction of the information signal from the sensor unit 1 is completed in step S11, the process proceeds to step S12. In step S12, the information signal from the sensor unit 1 is converted into a distance.

[0135] If the information signal from the sensor unit 1 is converted into a distance in step S2, then proceed to step S3, and calculate the width of the packaged object G based on the distance information converted in step S2.

[0136] Then enter step S14, further add the length information of the packaged object G from the width information of the packaged object G obtained in step S13, and calculate the width and length, that is, the overall shape of the packaged object G.

[0137] Next, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com