Garbage clearing and transporting system and method

A technology for garbage and clearing boxes, applied in garbage cleaning, trash cans, garbage collection, etc., can solve the problem that users and cleaning personnel are easily infected by viruses, and achieve the effect of reducing the risk of virus infection, reducing the risk of infection, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

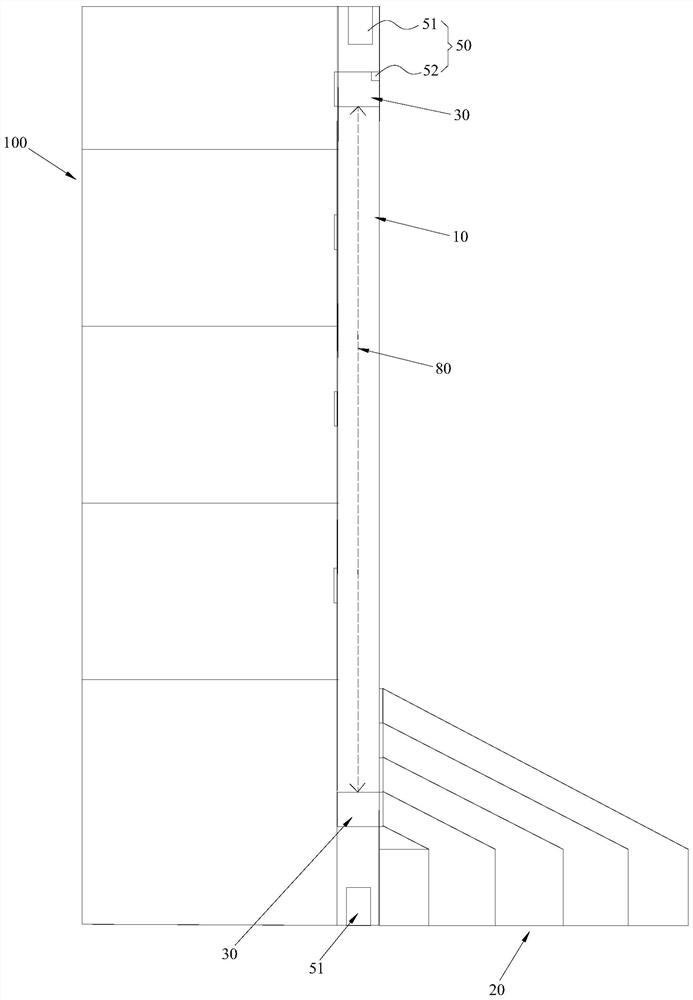

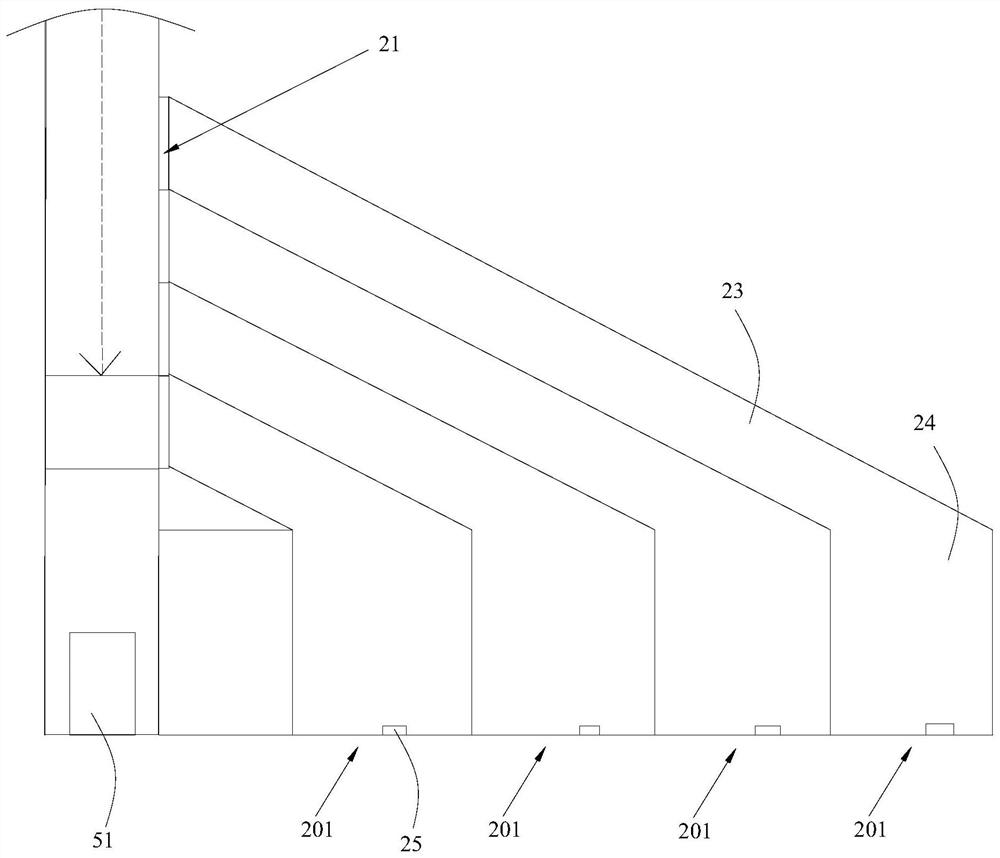

[0074] see figure 2 , the refuse storage bin 20 further includes a vertical section 24 extending vertically downward from the inclined section 23 . The inclined sections 23 of the four sub-boxes 201 are distributed sequentially along the vertical direction, and the vertical sections 24 of the four sub-boxes 201 are distributed sequentially along the horizontal direction.

[0075] see figure 2 The bottom of the garbage storage box 20 is provided with a first pressure sensor 25, specifically, the first pressure sensor 25 is located at the bottom of the vertical section 24, the first pressure sensor 25 is used to sense the weight of the garbage in the garbage storage box 20, and When the weight of the garbage in the garbage storage box 20 reaches the preset value, the feedback is sent to the removal robot 40, and the removal robot 40 runs to the corresponding garbage storage box 20 to hand over the garbage after receiving the feedback. Specifically, both the first pressure se...

Embodiment 2

[0078] The technical features of the garbage removal system in this embodiment are basically the same as those of the garbage removal system in Embodiment 1, the difference is that in this embodiment, please refer to Figure 6 , the garbage storage box 20 also includes a horizontal section 29, and the horizontal section 29 extends horizontally from the inclined section 23 outwards. The inclined sections 23 of the four sub-boxes 201 are distributed sequentially along the vertical direction, and the horizontal sections 29 of the four sub-boxes 201 are also distributed sequentially along the vertical direction.

[0079] see Figure 6 to Figure 8 The bottom of the garbage storage box 20 is provided with a conveyor belt 26, and the conveyor belt 26 is located at the bottom of the horizontal section 29. The garbage enters from the second garbage receiving port 21 and slides directly to the conveyor belt 26 via the inclined section 23, and passes through the conveyor belt 26. to del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com