Production process and production system of dodecylbenzene sulfonic acid

A technology of dodecylbenzenesulfonic acid and dodecylbenzene, applied in the preparation of sulfonic acid, organic chemistry and other directions, can solve the problems of sulfonated product quality impact, production line shutdown, high process air requirements, etc., to shorten the time The effect of the occurrence process, the use of less equipment costs, and the reduction of process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

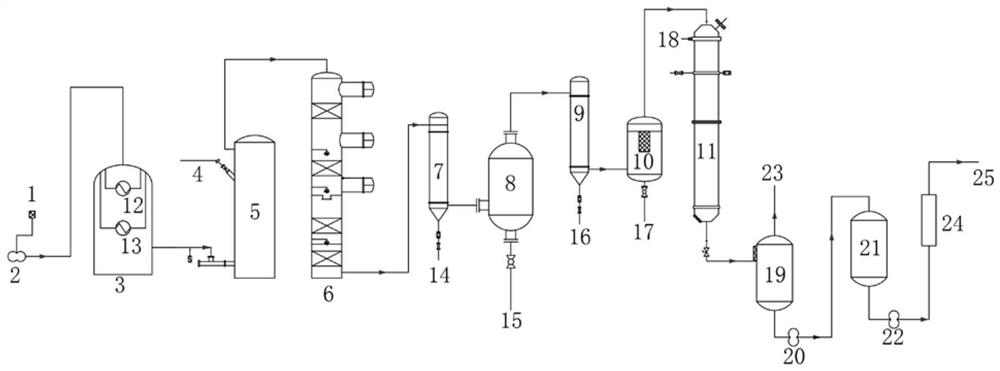

[0037] The present embodiment provides a kind of production technology of dodecylbenzenesulfonic acid, comprising:

[0038] After the external air is removed by the filter, it enters the Roots blower for compression treatment, and the pressure at the outlet of the blower can reach 55KPa; the pressurized hot air then enters the air low-temperature condenser to cool down at about 8°C, and then directly flows from the bottom of the sulfur furnace Enter (for comparison, the cooling gas of a pipeline continues to be carried out according to the original process pipeline), contact with the liquid sulfur transported by the liquid sulfur pump on the upper part of the furnace, ignite and burn, the flow rate of liquid sulfur is 330kg / h, and the sulfur furnace exits SO 2 / air mixed gas temperature at 650°C; high temperature SO 2 / The air mixed gas is cooled to 450°C by the partition air cooler and enters the conversion tower, and the gas temperature at the outlet of the conversion tower ...

Embodiment example 2

[0045] The present embodiment provides a kind of production technology of dodecylbenzenesulfonic acid, comprising:

[0046] After the outside air is removed by the filter, it enters the Roots blower for compression treatment, and the pressure at the outlet of the blower can reach 58KPa; the pressurized hot air then enters the air low-temperature condenser to cool down at about 10°C, and then directly flows from the bottom of the sulfur furnace Enter, contact with the liquid sulfur transported by the liquid sulfur pump in the upper part of the furnace, ignite and burn, the flow rate of liquid sulfur is 350kg / h, and the outlet of the sulfur burning furnace is SO 2 / air mixed gas temperature at 650°C; high temperature SO 2 / The air mixed gas is cooled to 450°C by the partition air cooler and enters the conversion tower, and the gas temperature at the outlet of the conversion tower is 450°C; the SO at the outlet of the conversion tower 3 The / air mixed gas enters the first-stage ...

Embodiment example 3

[0052] The present embodiment provides a kind of production technology of dodecylbenzenesulfonic acid, comprising:

[0053] After the outside air is removed by the filter, it enters the Roots blower for compression treatment, and the pressure at the outlet of the blower can reach 60KPa; the pressurized hot air then enters the air low-temperature condenser to cool down at about 8°C, and then directly flows from the bottom of the sulfur furnace Enter, contact with the liquid sulfur transported by the liquid sulfur pump in the upper part of the furnace, ignite and burn, the flow rate of liquid sulfur is 354kg / h, and the outlet of the sulfur burning furnace is SO 2 / air mixed gas temperature at 650°C; high temperature SO 2 / The air mixed gas is cooled to 450°C by the partition air cooler and enters the conversion tower, and the gas temperature at the outlet of the conversion tower is 450°C; the SO at the outlet of the conversion tower 3 The / air mixed gas enters the first-stage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com