Armored cable rounding equipment

An armored cable, full-circle technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of cable fire resistance decline, uneven fireproof powder filling, and uniform filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

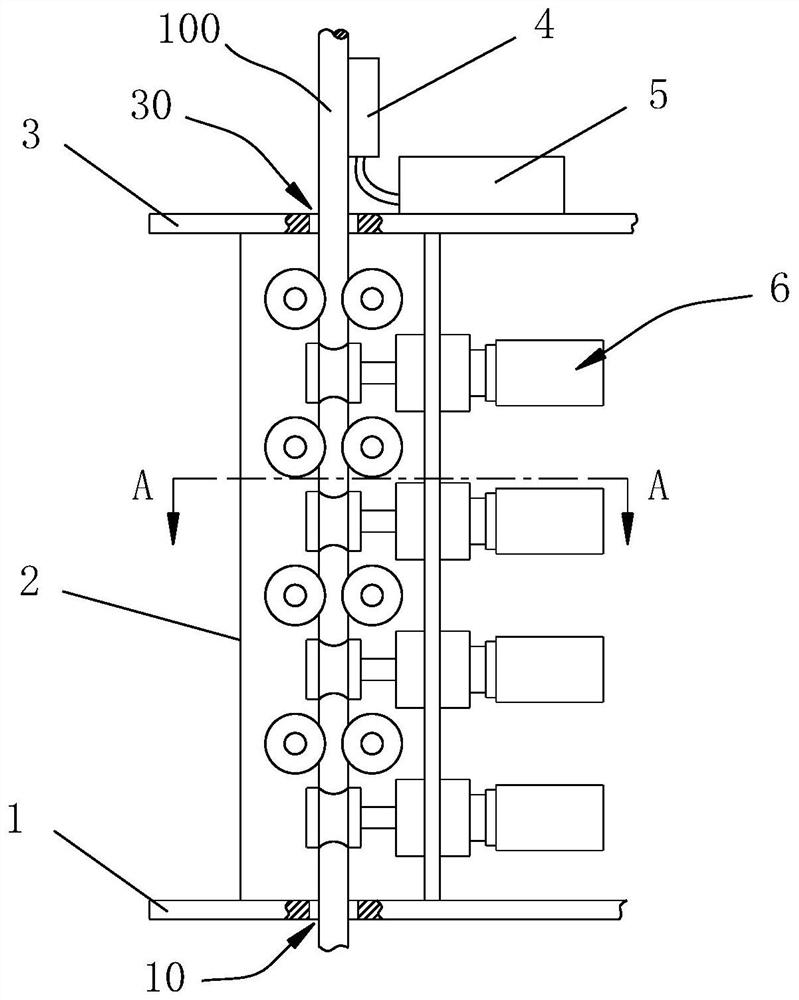

[0020] refer to figure 1 The armored cable 100 full circle equipment provided in this embodiment is a vertical structure, which is installed on the production line of the armored cable 100, after a metal sheath armoring and powder filling process, and the cable passes through the metal sheath. The armoring and powder filling process welds a circular metal sheath and fills a fireproof powder filler, then processes it into an armored cable 100, and then enters the round device of the armored cable 100, wherein the entire armored cable 100 The circular equipment includes: a frame, a predetermined number of full-circle mechanisms 6 and a vibration mechanism.

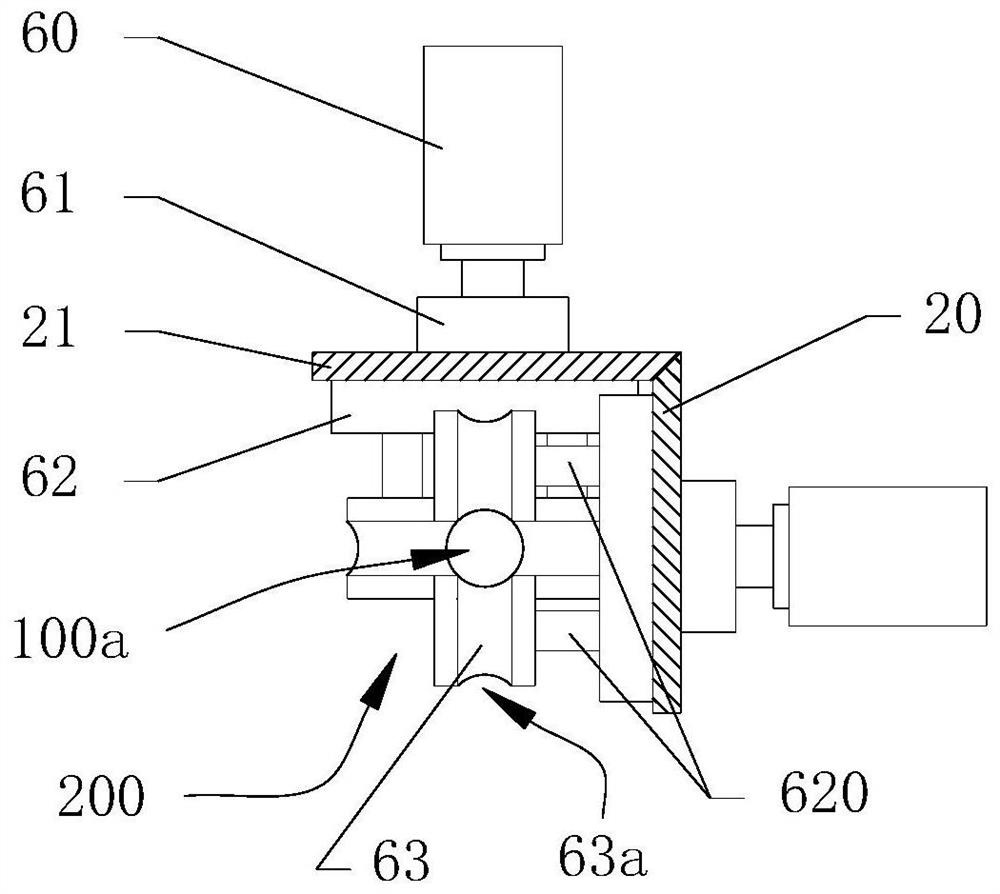

[0021] refer to Figure 5 , at the same time, the present embodiment provides a deceleration commutator 62 for the armored cable 100 full circle equipment, which includes a deceleration commutator input shaft 622 and a deceleration commutator input shaft 622 is provided with a For the output shaft 620 of the deceleration c...

Embodiment 2

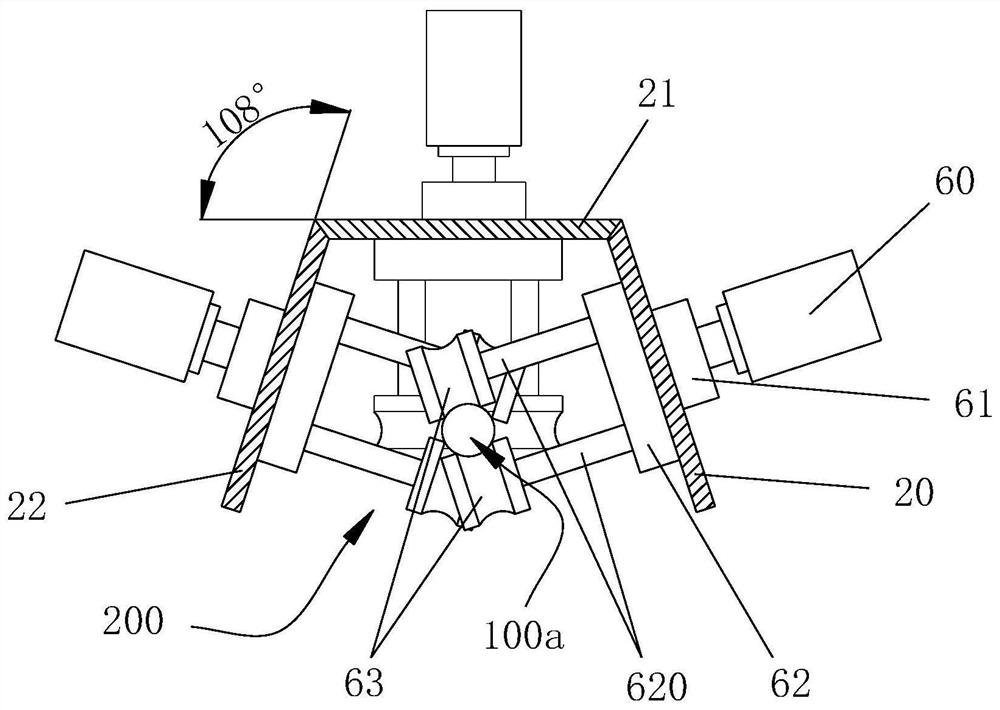

[0028] refer to figure 2 , image 3 as well as Figure 4 , this embodiment 2 has been improved on the basis of the scheme of embodiment 1, and the unimproved parts are consistent with embodiment 1, and its improvement scheme: the support angle frame 2 includes three support plates, and the three support plates They are respectively the first support plate 20, the second support plate 21 and the third support plate 22. The first support plate 20, the second support plate 21 and the third support plate 22 are connected in turn to form the In the full-circle space 200, the included angle between two adjacent support plates is 108° or 120°, and the full-circle mechanisms 6 are installed on three support plates respectively, and are arranged alternately with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com