Two-roll extrusion coating production method of energy storage electrode

A technology for energy storage electrodes and production methods, applied in electrode rolling/calendering, battery electrodes, electrode manufacturing, etc., can solve the problems of reducing battery energy density, wasting materials, and large amount of positive electrode material dressings, etc. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

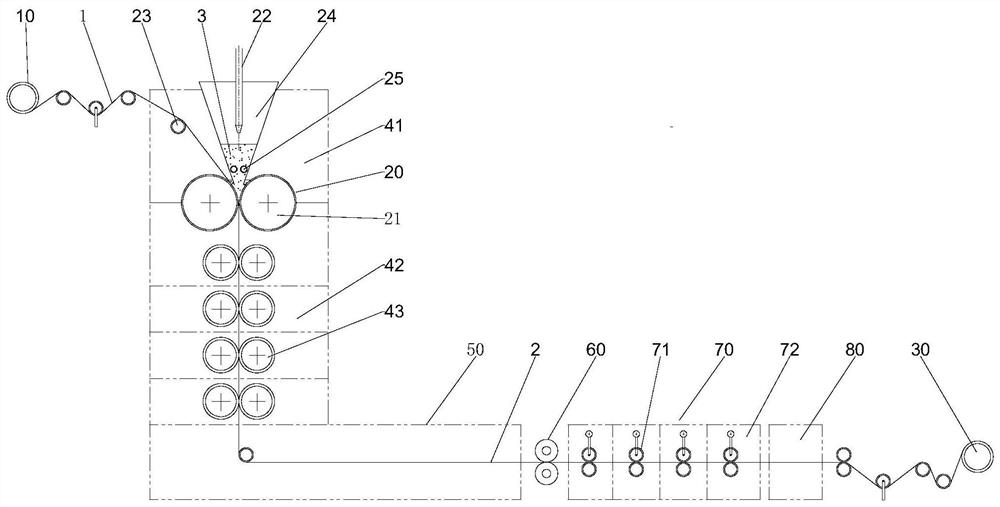

[0058] like figure 1 As shown, it is a schematic structural diagram of the two-roll extrusion coating production equipment for energy storage electrodes in Example 1 of the two-roll extrusion coating production method for energy storage electrodes of the present invention. The double-roll extrusion coating production equipment for the energy storage electrode includes:

[0059] Unwinding mechanism 10: for unwinding the current collector strip 1;

[0060] Extrusion coating device 20: used for extrusion coating the electrode material layer on the current collector strip 1 and obtaining the electrode strip 2;

[0061] Winding mechanism 30 : used for winding the prepared electrode strip 2 .

[0062] Specifically, the extrusion coating device 20 includes a group of extrusion rollers, and the group of extrusion rollers includes two extrusion rollers 21 whose axes are parallel to each other; The feeding device of the electrode material 3;

[0063] Between the unwinding mechanism ...

Embodiment 2

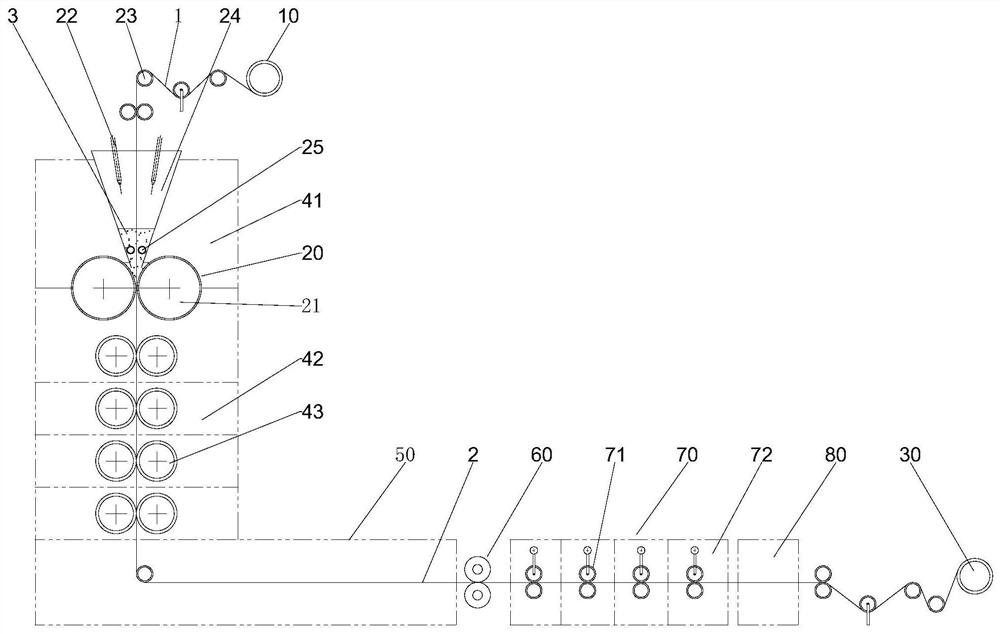

[0090] like figure 2 As shown, it is a schematic structural diagram of a two-roll extrusion coating production equipment for energy storage electrodes in Example 2 of the two-roll extrusion coating production method for energy storage electrodes of the present invention. The double-roll extrusion coating production equipment for the energy storage electrode includes:

[0091] Unwinding mechanism 10: for unwinding the current collector strip 1;

[0092] Extrusion coating device 20: used for extrusion coating the electrode material layer on the current collector strip 1 and obtaining the electrode strip 2;

[0093] Winding mechanism 30 : used for winding the prepared electrode strip 2 .

[0094] Specifically, the extrusion coating device 20 includes a group of extrusion rollers, and the group of extrusion rollers includes two extrusion rollers 21 whose axes are parallel to each other; The feeding device of the electrode material 3;

[0095] Between the unwinding mechanism 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com