A Welding Method for Circumferential Weld on Exhaust Tube

A technology of circular welding seam and welding method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of reduced welding speed, increased welding time, increased welding difficulty, etc., and achieves the goal of ensuring accuracy and avoiding offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

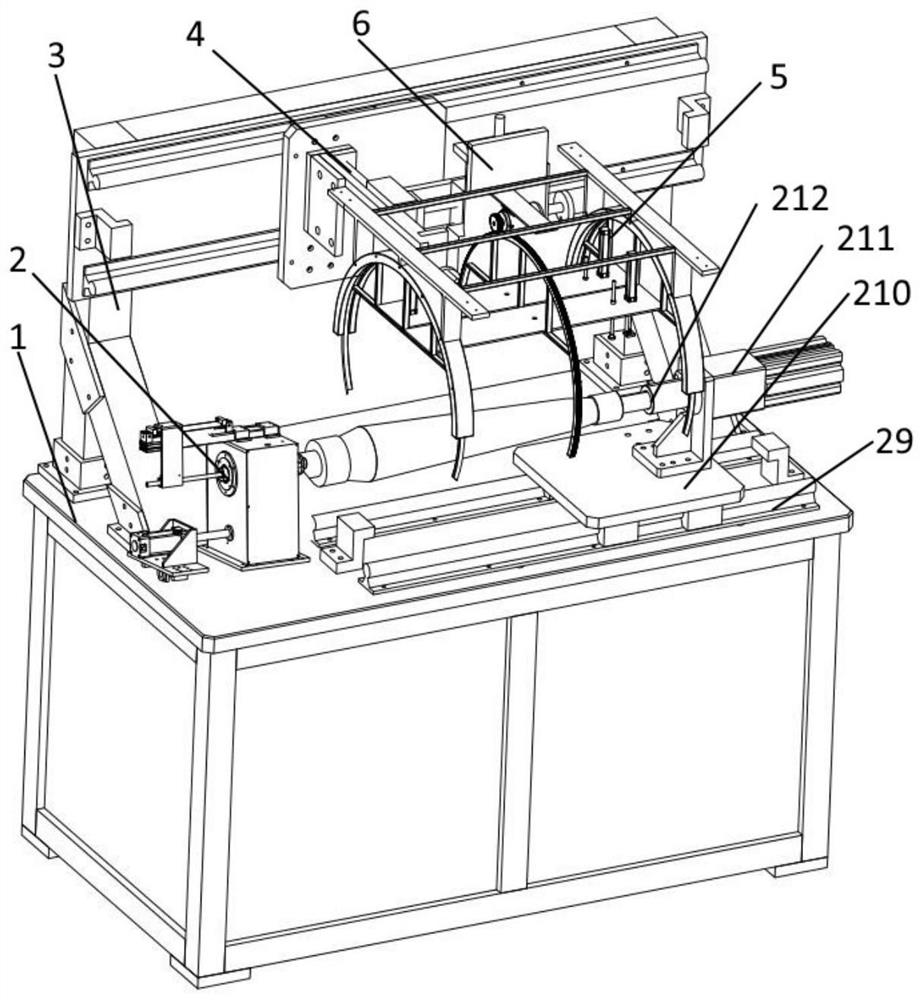

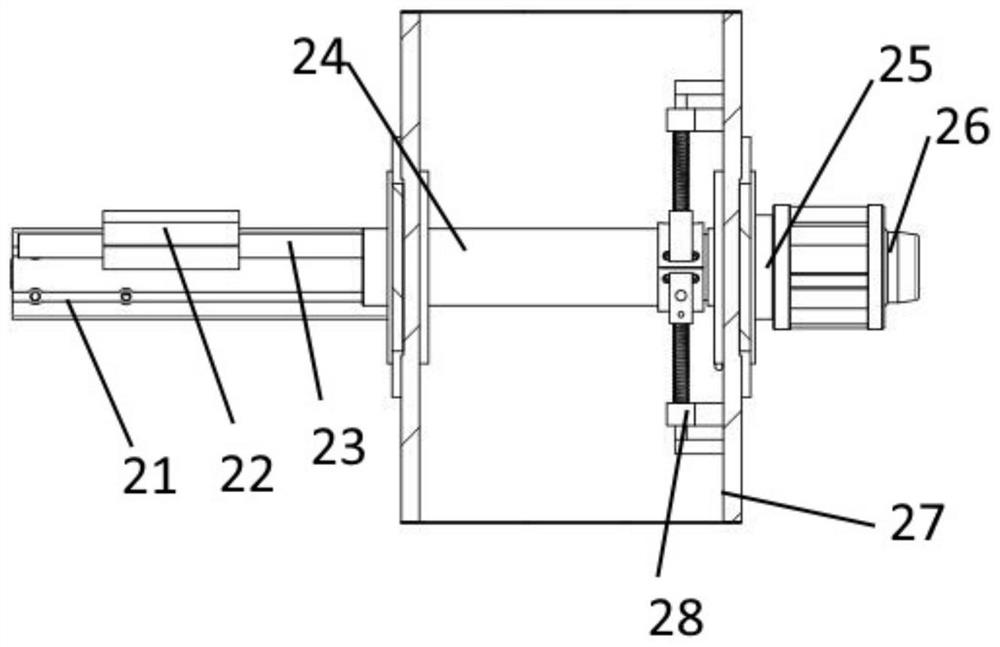

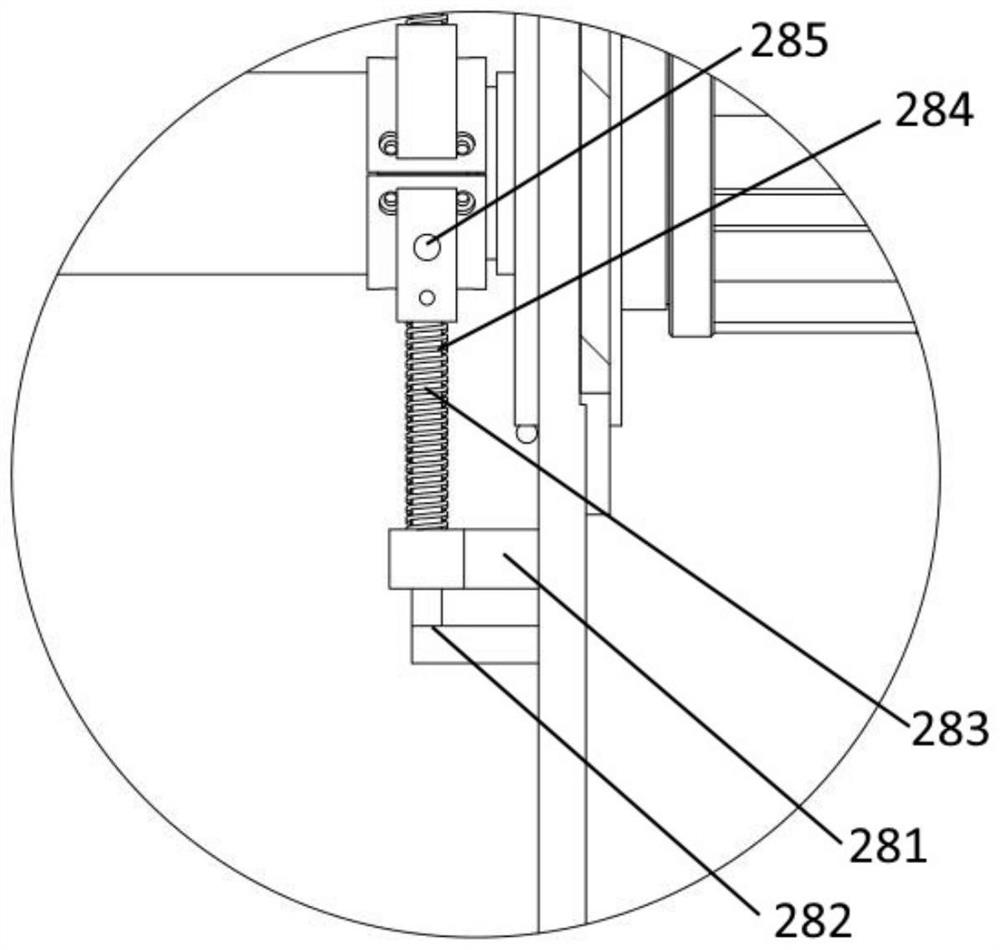

[0037] After the applicant's research and analysis, this problem occurs (when the diameter of the exhaust pipe is large, the area of the circular seam that needs to be welded will increase at this time, which will increase the difficulty of welding, and then will also increase the welding time. , which in turn causes a decrease in the welding rate), the reason is that most of the existing welding devices have only one welding position, and the welding time is too long during the welding work. Some enterprises will choose to use two welding devices in order to increase the welding rate. And then by setting a plurality of welding devices, and then can finish the welding work to exhaust pipe simultaneously, but most welding devices all are to be positioned at the exhaust pipe length direction, and then when the diameter of exhaust pipe is bigger, with single The welding time of the welding device is the same, and thus the welding time cannot be reduced. Only when there are multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com