A dismantling device for troubleshooting an air compressor intake valve and a method of using the same

A technology of air compressors and air intake valves, which is applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of inability to achieve multi-station demolition operations and general demolition efficiency, and achieve improved demolition efficiency, Reduce labor intensity and use reasonable and perfect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

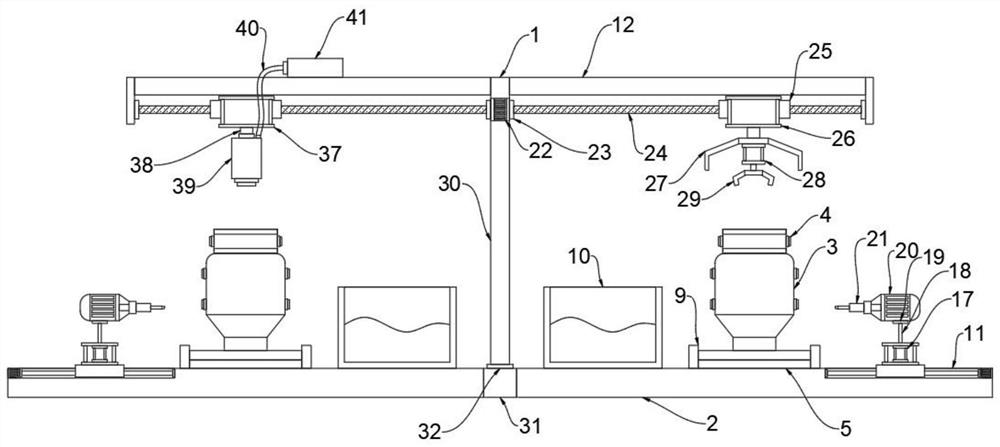

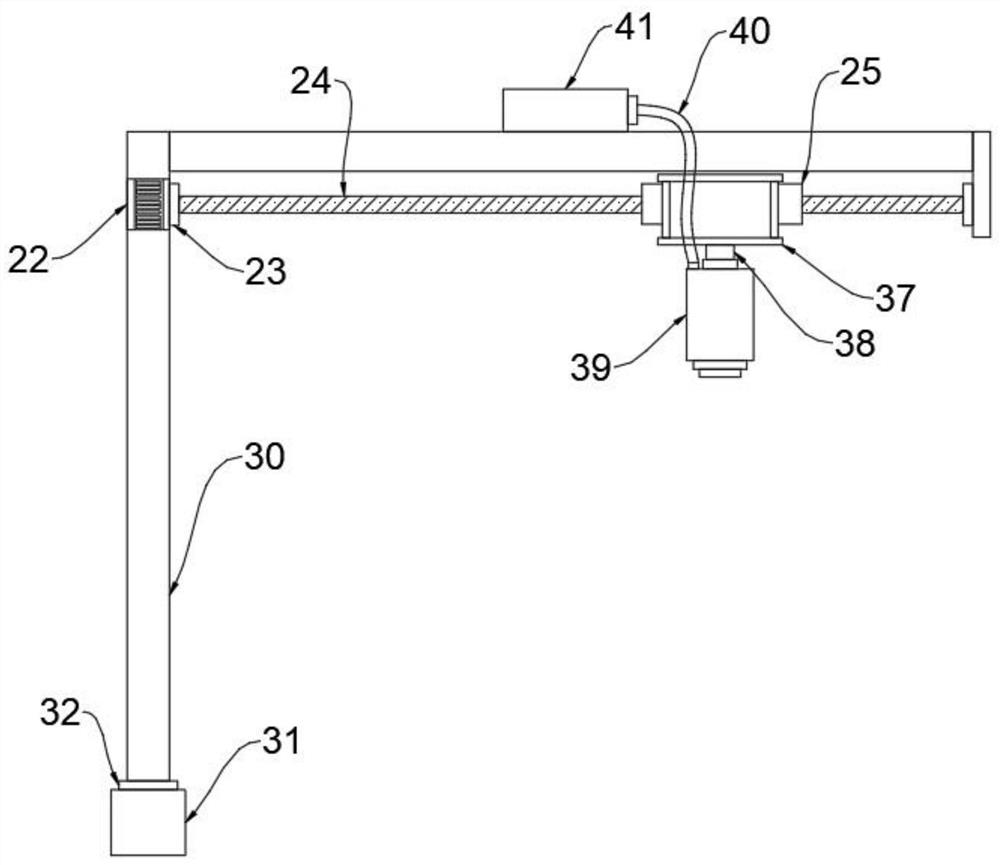

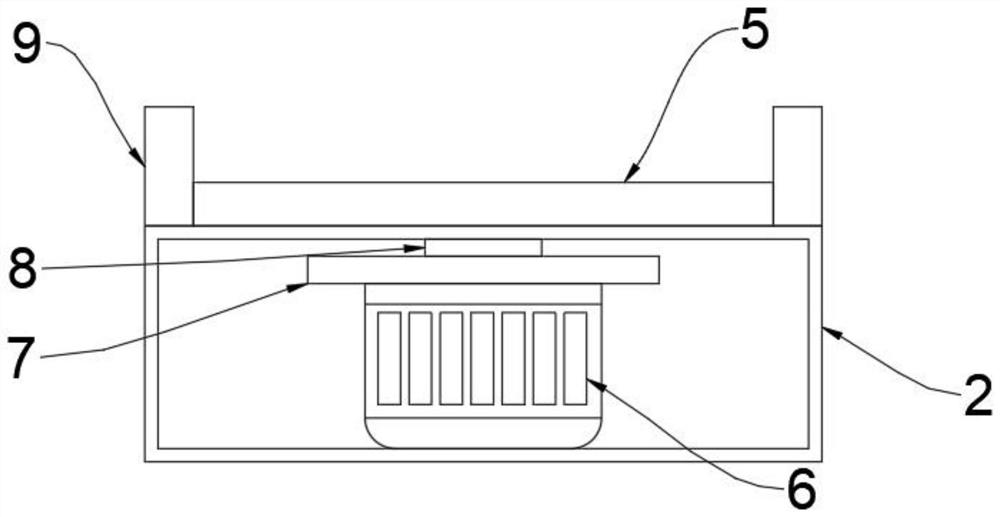

[0031] see Figure 1-5, an embodiment provided by the present invention: a dismantling device for fault handling of an air compressor intake valve, comprising an intake valve fault dismantling mechanism body 1, and the intake valve fault dismantling mechanism body 1 is dismantled by an operation platform 2 and a side part. The mechanism 11 and the upper dismantling mechanism 12 are composed. A rotary table driving mechanism 31 is fixedly installed at the intermediate position of the adjacent operation platform 2, and three rotary table driving mechanisms 31 are installed, and a second rotary table driving mechanism 31 is fixedly installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com