Battery replacement grabbing device and control method for battery replacement grabbing device

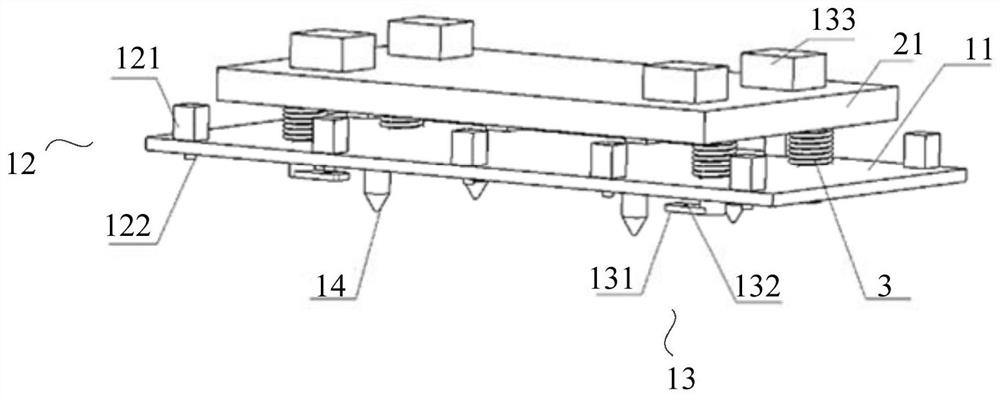

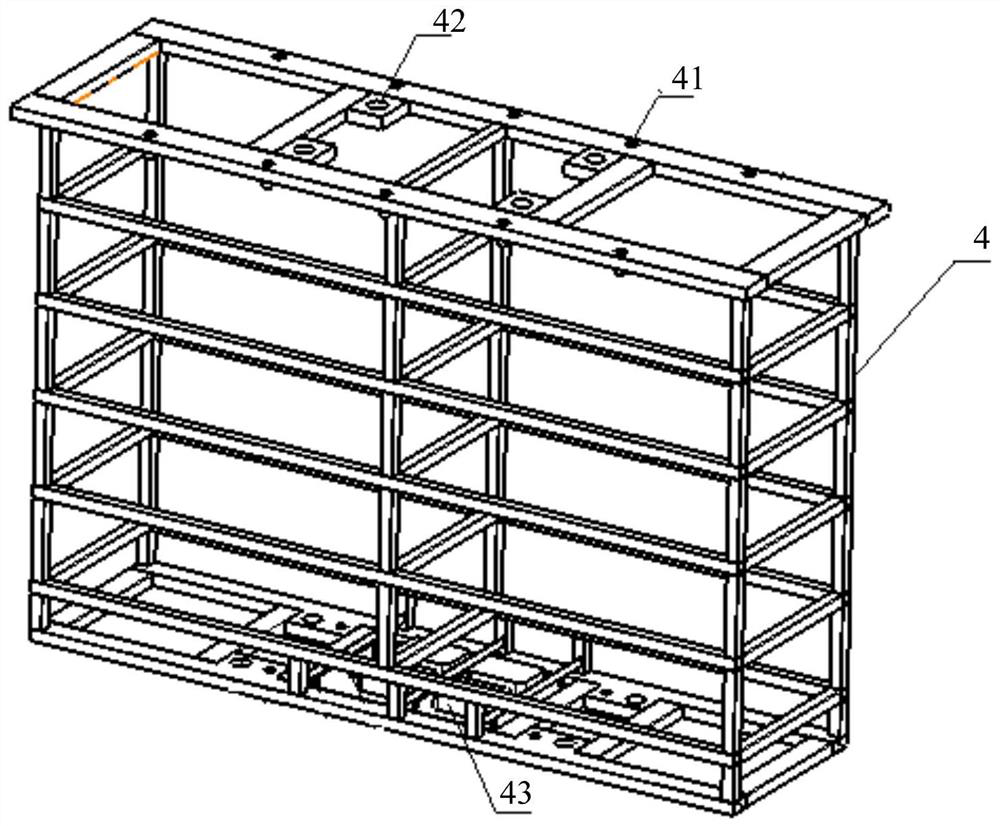

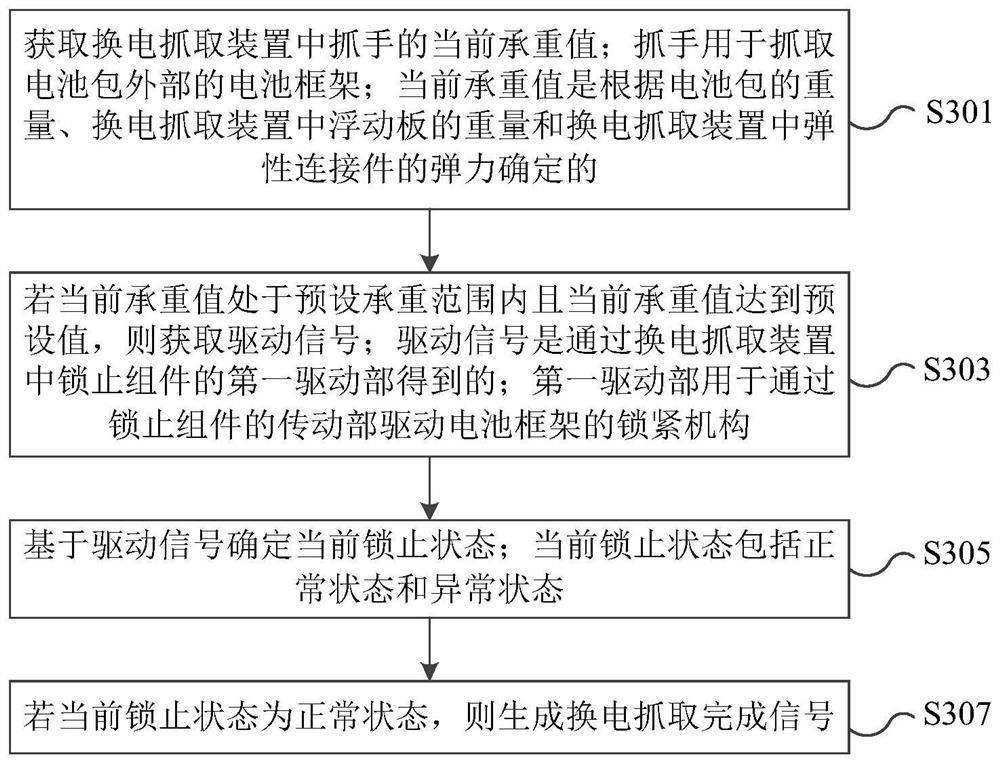

A technology of grabbing device and control method, which is applied to the control of battery swapping grabbing devices and the field of battery swapping grabbing devices, which can solve the problems of uneven load weight on the body, safety risks, and difficulty in positioning the battery swapping grabbing device in the station, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical scheme in the present application embodiment will be described in the present application, and it is understood that the described embodiments are intended to be described herein, not all of the embodiments of the present application. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without making creative labor are the scope of the present application.

[0042] It should be noted that the specification and claims of the present application and the terms "first", "second", "second", and the like are used to distinguish a similar object without having to describe a particular order or ahead order. It is to be understood that the data such as use can be interchangeable in appropriate, so that the embodiments of the present application described herein can be implemented in the order other than those illustrated or described herein. Moreover, the terms "including" and "having" and any ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap