A concrete point compaction system and its application process

A concrete and dense technology, which is applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve problems such as left and right shaking, increased construction costs, uneven concrete areas, etc., to reduce manufacturing costs, improve compactness, and compactness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

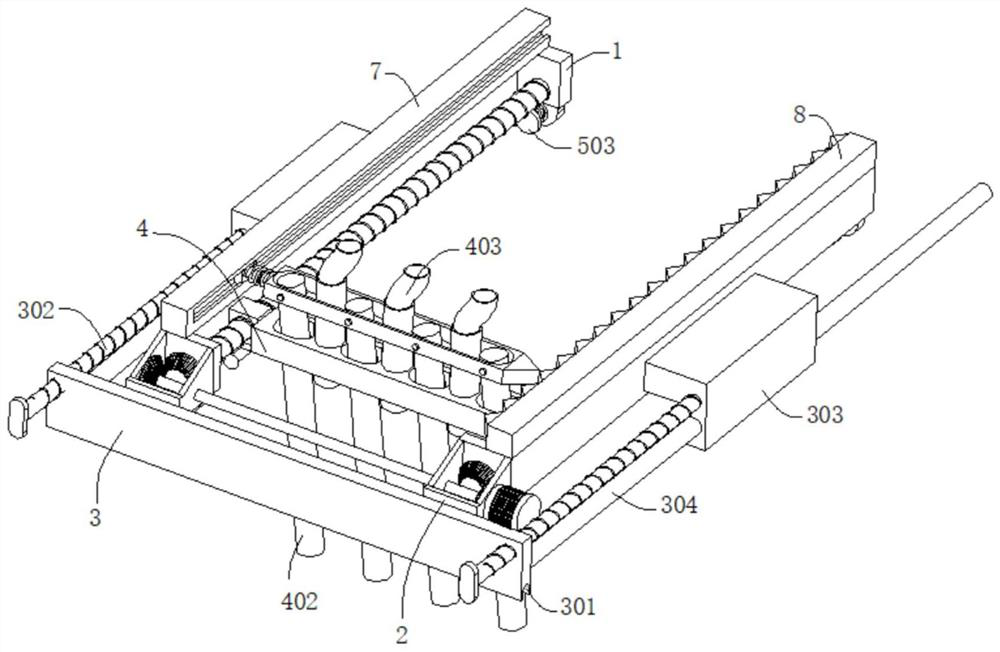

[0040] refer to Figure 1-9 , a concrete point compaction system, comprising two fixing frames 1, the outer walls of the two fixing frames 1 are fixedly connected with a positioning block 303, and the outer wall of the positioning block 303 is rotatably connected with a threaded rod 302 through a first bearing, and the threaded rod 302 is far away from the positioning One end of the block 303 is fixedly connected with a handle 3021, the outer wall of the threaded rod 302 is threadedly connected with a positioning plate 3, the bottom wall of the positioning plate 3 is dug with a draw-in groove 301, the outer wall of the positioning plate 3 is fixedly connected with a guide rod 304, and the positioning block 303 is slidingly connected to the The outer wall of the guide rod 304 and the outer walls of the two fixed frames 1 are fixedly connected with the housing 2, the outer wall of the housing 2 is connected with the first motor 201, the output end of the first motor 201 is connec...

Embodiment 2

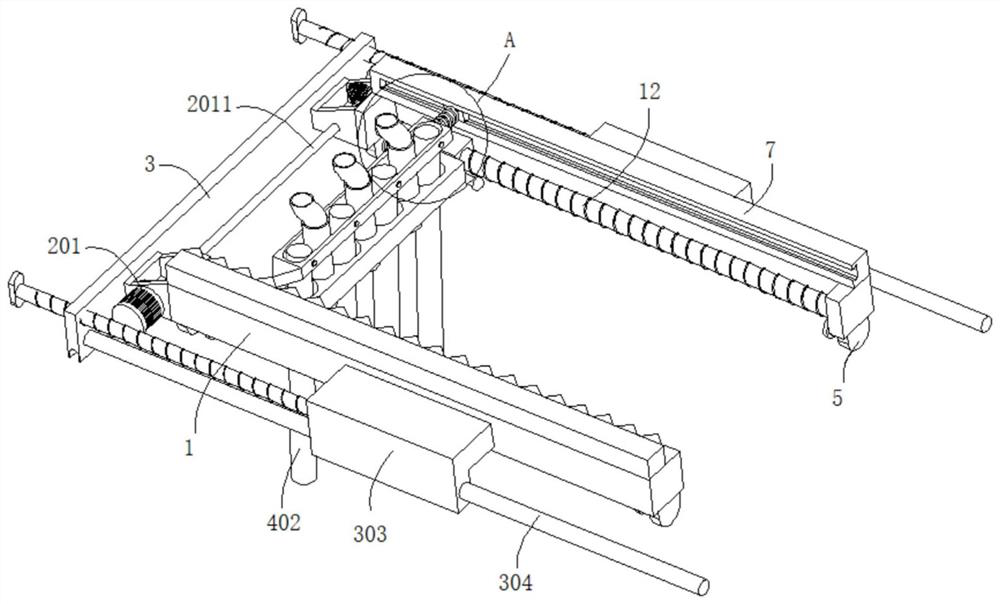

[0043] refer to Figure 1-10 , a concrete point compaction system, which is basically the same as that of Embodiment 1, furthermore, both ends of the fixed frame 1 are fixedly connected with connecting plates 5, and the outer walls of the two connecting plates 5 are connected with travel switches 501, two The travel switches 501 are electrically connected to the first motor 201 , and the bottom of the sleeve 122 is connected with a knocking member 6 matched with the travel switches 501 .

[0044] The knocking member 6 includes a knocking rod 601 and two knocking balls 602 , the knocking rod 601 is fixedly connected to the bottom of the sleeve 122 , and the two knocking balls 602 are respectively connected to two sides of the knocking rod 601 .

[0045] The outer wall of the connecting plate 5 is connected with a first elastic element 502, and the end of the first elastic element 502 far away from the connecting plate 5 is connected with a force plate 503, and the outer walls o...

Embodiment 3

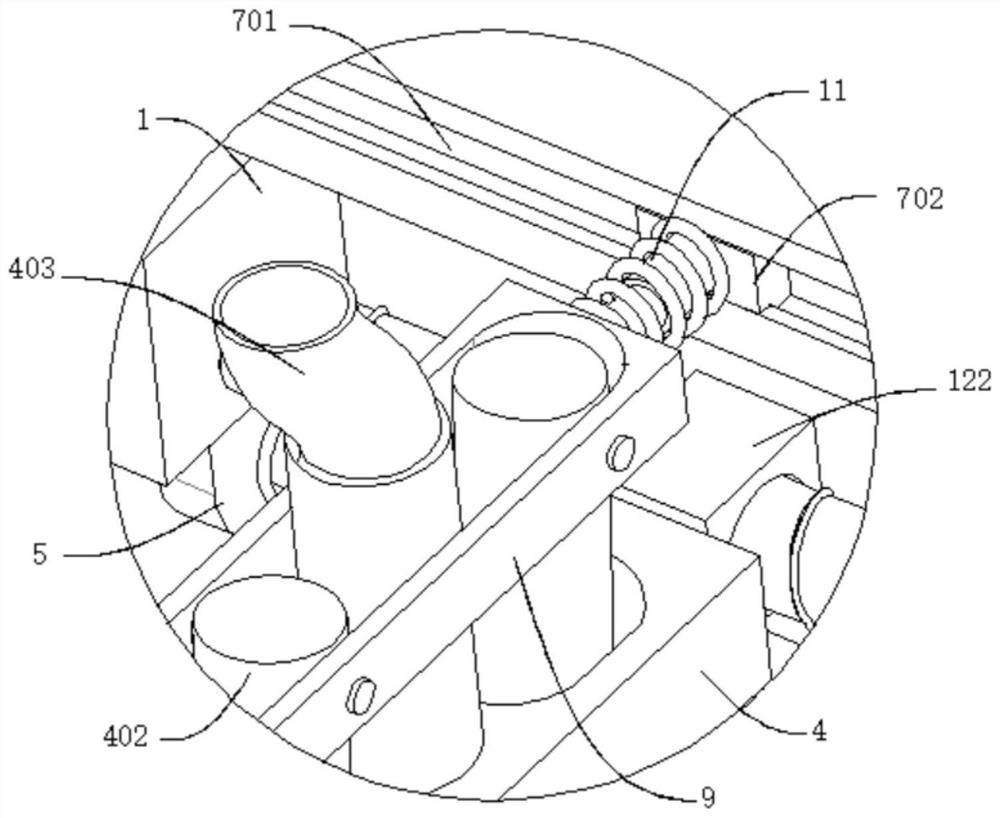

[0048] refer to Figure 1-10 , a concrete point compaction system, which is basically the same as that of Embodiment 2, furthermore, the tops of the two fixing frames 1 are respectively connected with a first connecting block 7 and a second connecting block 8, and the outer wall of the first connecting block 7 is excavated There is a chute 701 , the inner wall of the chute 701 is slidably connected with a slider 702 , and the outer wall of the second connecting block 8 is connected with a protrusion 801 .

[0049] The chute 701 is configured as a convex groove, and the slider 702 is adapted to the chute 701 .

[0050] The top of the vibrating rod 402 is connected with a movable plate 9, and the movable plate 9 is movably connected with the top of the vibrating rod 402 through a pin shaft. One end of the block 10 is connected with a spring telescopic rod 11 , and the end of the spring telescopic rod 11 away from the movable plate 9 is connected to the outer wall of the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com